Silicon rubber/polypropylene thermoplastic vulcanizate and preparation method thereof

A technology of thermoplastic vulcanizate and polypropylene, which is applied in the field of polymer material processing, can solve the problems of reducing material elasticity and high temperature resistance, limited compatibilizing effect, and large molecular weight of compatibilizer, etc., and achieves excellent sealing performance and good physical mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

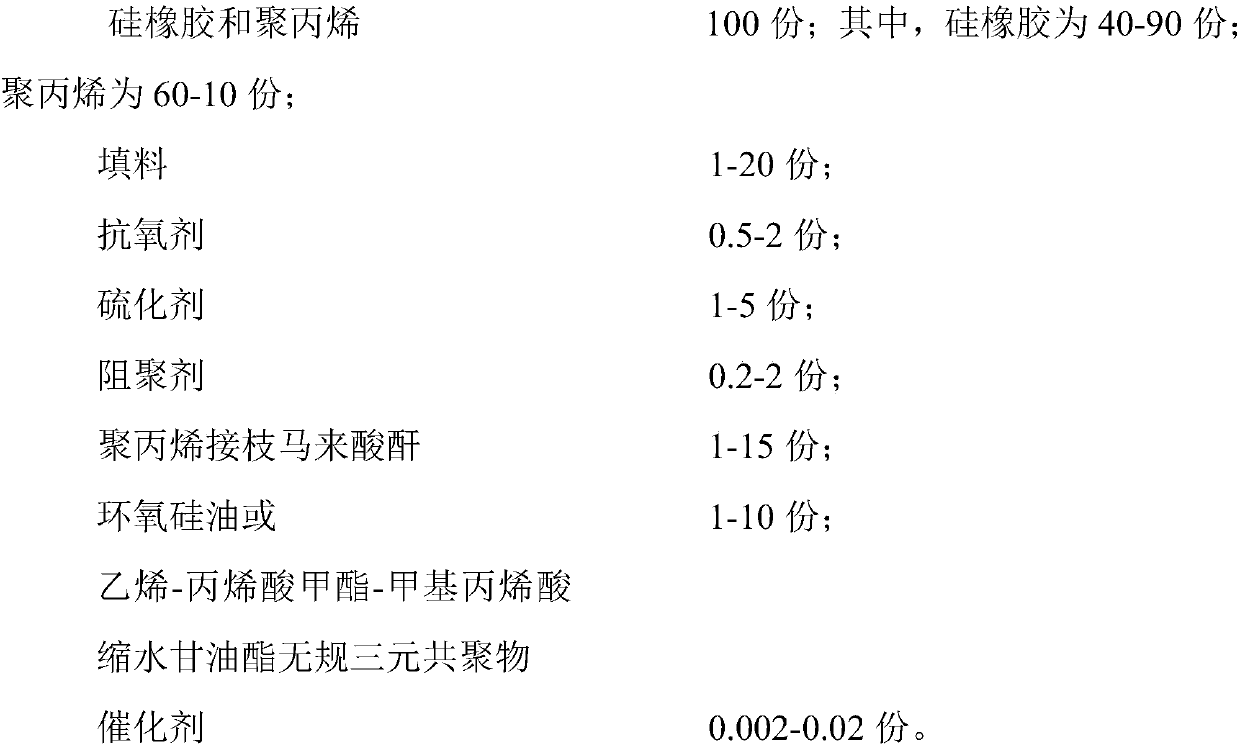

[0038] The basic composition and mass parts of the selected raw materials are as follows:

[0039]

[0040] According to the above formula, the silane-modified white carbon black and the methyl vinyl silicone rubber were fully mixed uniformly in an internal mixer at room temperature and 70 rpm to prepare a silicone rubber compound with a relatively high viscosity. Mix polypropylene and methyl vinyl silicone rubber at 220°C, add polypropylene grafted maleic anhydride, epoxy silicone oil, octadecyl dimethyl tertiary amine and antioxidant 1010 in proportion, wait until After mixing evenly, discharge the material and cool it to room temperature; then mix it evenly with vulcanizing agent and polymerization inhibitor at room temperature to obtain a rubber-plastic premix; put the rubber-plastic premix in a twin-screw extruder, and set the vulcanization temperature to 240°C , with a rotating speed of 500 rpm, and dynamic vulcanization to obtain a silicone rubber / polypropylene therm...

Embodiment 2

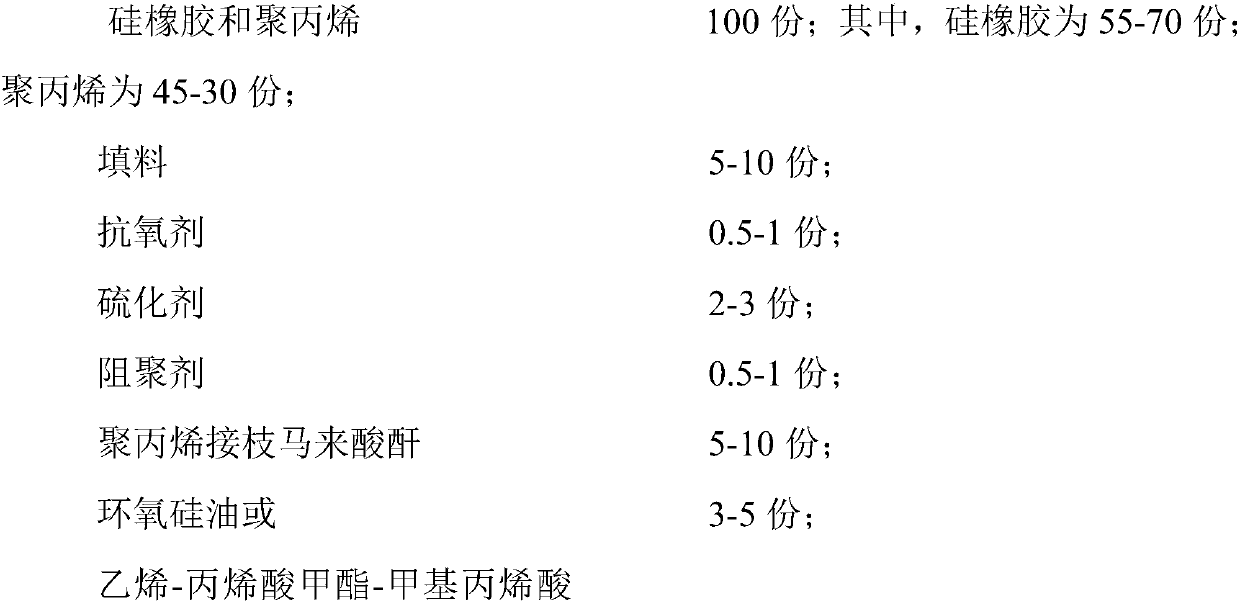

[0044] The basic composition and mass parts of the selected raw materials are as follows:

[0045]

[0046] According to the above formula, the silane-modified silica and methyl vinyl silicone rubber were fully mixed evenly in an internal mixer at room temperature and 70 rpm to prepare a silicone rubber compound with relatively high viscosity. Mix polypropylene and methyl vinyl silicone rubber at 180°C, add polypropylene grafted maleic anhydride, ethylene-methyl acrylate-glycidyl methacrylate random terpolymer, three Ethylamine and antioxidant 1010, after being mixed uniformly, the material is discharged and cooled to room temperature; then mixed with vulcanizing agent and polymerization inhibitor at room temperature to obtain a rubber-plastic premix; the rubber-plastic premix is placed in a twin-screw extruder In the machine, set the vulcanization temperature to 200°C and the rotation speed to 500rpm, and dynamically vulcanize to obtain a silicone rubber / polypropylene ther...

Embodiment 3

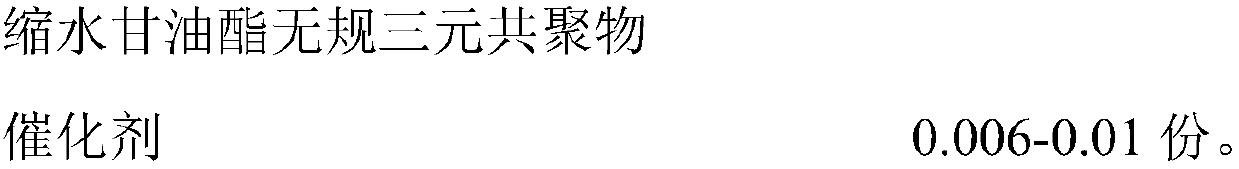

[0050] The basic composition and mass parts of the selected raw materials are as follows:

[0051]

[0052]

[0053] According to the above formula, the silane-modified white carbon black and methyl vinyl phenyl silicone rubber were fully mixed evenly in an internal mixer at room temperature and 70 rpm to prepare a silicone rubber compound with relatively high viscosity. Mix polypropylene and methyl vinyl phenyl silicone rubber compound at 260°C, add polypropylene grafted maleic anhydride, ethylene-methyl acrylate-glycidyl methacrylate random terpolymer in proportion , octadecyl dimethyl tertiary amine and antioxidant 1010, after being mixed evenly, the material is discharged and cooled to room temperature; then mixed with vulcanizing agent and polymerization inhibitor at room temperature to obtain a rubber-plastic premix; the rubber-plastic The premix was placed in a twin-screw extruder, the vulcanization temperature was set at 280° C., and the rotation speed was 700 rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com