Preparation method of photocatalytic ultrafilter membrane material with visible light activity

An ultrafiltration membrane and visible light technology, applied in the field of photocatalytic materials, can solve the problems of easy loss of TiO2, the invasion of nanoparticles into the human body and other species, and limit the application of titanium dioxide photocatalysis, so as to promote the transfer and transfer of electrons and improve hydrophilicity and anti-pollution properties, and the effect of improving the photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

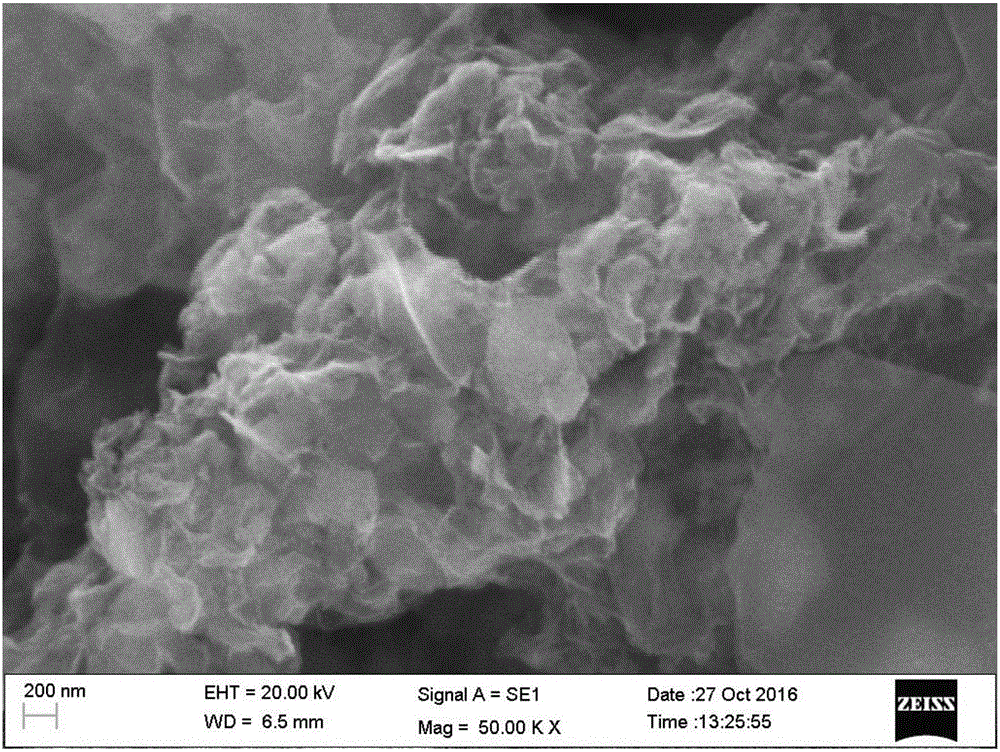

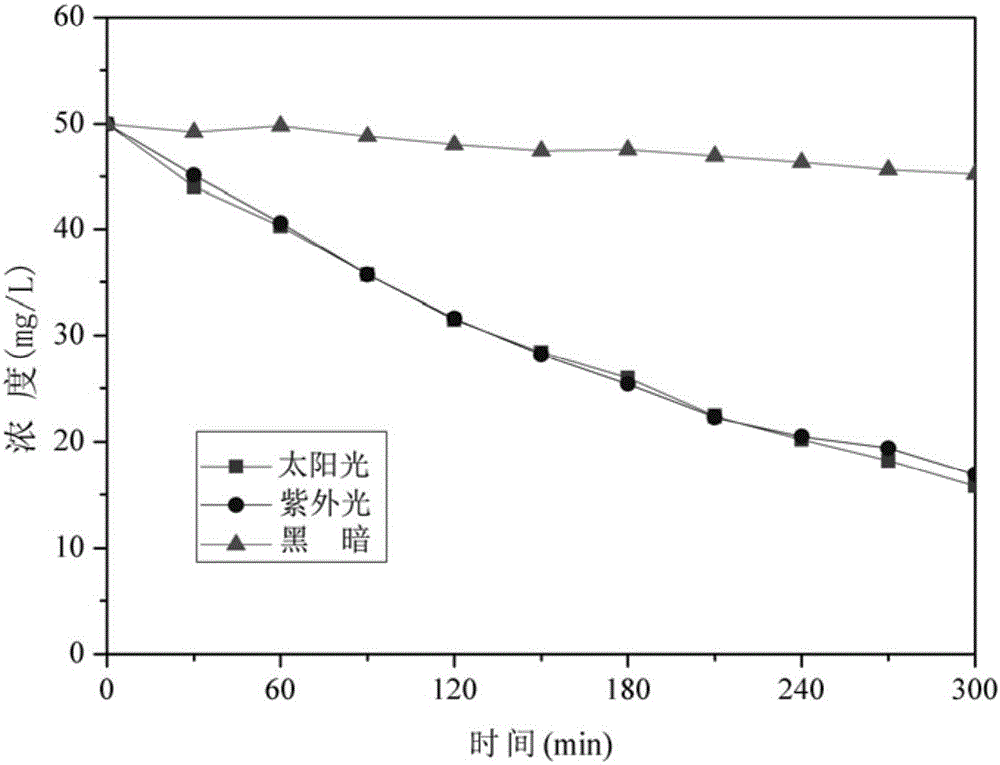

[0025] Such as Figure 1 ~ Figure 2 Shown, a kind of preparation method of photocatalytic ultrafiltration membrane material with visible light activity comprises the following steps:

[0026] (1) Preparation of N-TiO 2 Powder: Mix 10ml of butyl titanate with 40ml of absolute ethanol to form solution A, mix 0.486g of urea, 10ml of absolute ethanol, 4ml of pure water and 2ml of glacial acetic acid, and adjust the pH to 2 to form solution B. Add solution B to solution A drop by drop, continue to stir for 30 minutes to make it completely mixed, let it stand for about 3 hours to form a gel, put it in a blast drying oven for 24 hours at 100°C, grind it after cooling, put it in Heating to 500°C for 2 hours in a resistance furnace at a rate of 2°C / min, then taking it out after natural cooling to obtain N-TiO 2 powder.

[0027] (2) Preparation of N-TiO 2 / GO particles: measure 0.025g GO and pour it into 100mL pure water, ultrasonically oscillate to make it evenly dispersed, then me...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 is only:

[0034] The volume ratio of butyl titanate to absolute ethanol in solution A in S01 is 1:6, the volume ratio of absolute ethanol in solution B to butyl titanate in solution A is 1:0.5, pure water and butyl titanate The volume ratio of glacial acetic acid to butyl titanate is 1:2, the volume ratio of glacial acetic acid to butyl titanate is 1:4, the mass ratio of urea to butyl titanate is 1:8, and the solution used to adjust pH is 6mol / L hydrochloric acid. The pH is 1.5.

[0035] The temperature during drying in S01 was 60°C, and during calcination, the temperature was raised to 500°C for 2 hours at a rate of 1°C / min.

[0036] GO and N-TiO in S02 2 The mass ratio of the powder is 1:19, the high temperature environment is 150° C., and the reaction time is 12 hours.

[0037] The mass percentage of polysulfone, N-methylpyrrolidone and polyvinylpyrrolidone is 15.6:84:0.4.

[0038] The thickness of the film...

Embodiment 3

[0041] The difference between this embodiment and embodiment 1 is only:

[0042] The volume ratio of butyl titanate in solution A to absolute ethanol in S01 is 1:5, the volume ratio of absolute ethanol in solution B to butyl titanate in solution A is 1:0.8, and pure water and butyl titanate The volume ratio of glacial acetic acid to butyl titanate is 1:3, the volume ratio of glacial acetic acid to butyl titanate is 1:6, the mass ratio of urea to butyl titanate is 1:15, and the solution used to adjust pH is 6mol / L hydrochloric acid. The pH is 2.2.

[0043] The drying temperature in S01 was 150°C, and the temperature was raised to 500°C for 2 hours at a rate of 3°C / min during calcination.

[0044] GO and N-TiO in S02 2 The mass ratio of the powder is 1:19, the high temperature environment is 200° C., and the reaction time is 20 h.

[0045] The mass percentage of polysulfone, N-methylpyrrolidone and polyvinylpyrrolidone is 20:78:2.

[0046] The thickness of the film applicato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com