Method for preparing non-fired and non-steamed bricks by using sintering dry desulphurization byproduct

A technology of non-burning, non-steaming bricks and desulfurization by-products is applied in the field of comprehensive utilization of resources, which can solve the problems of few desulfurization by-products and comprehensive utilization problems, and achieve the effects of improving early mechanical properties, improving mechanical properties, and product energy saving and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

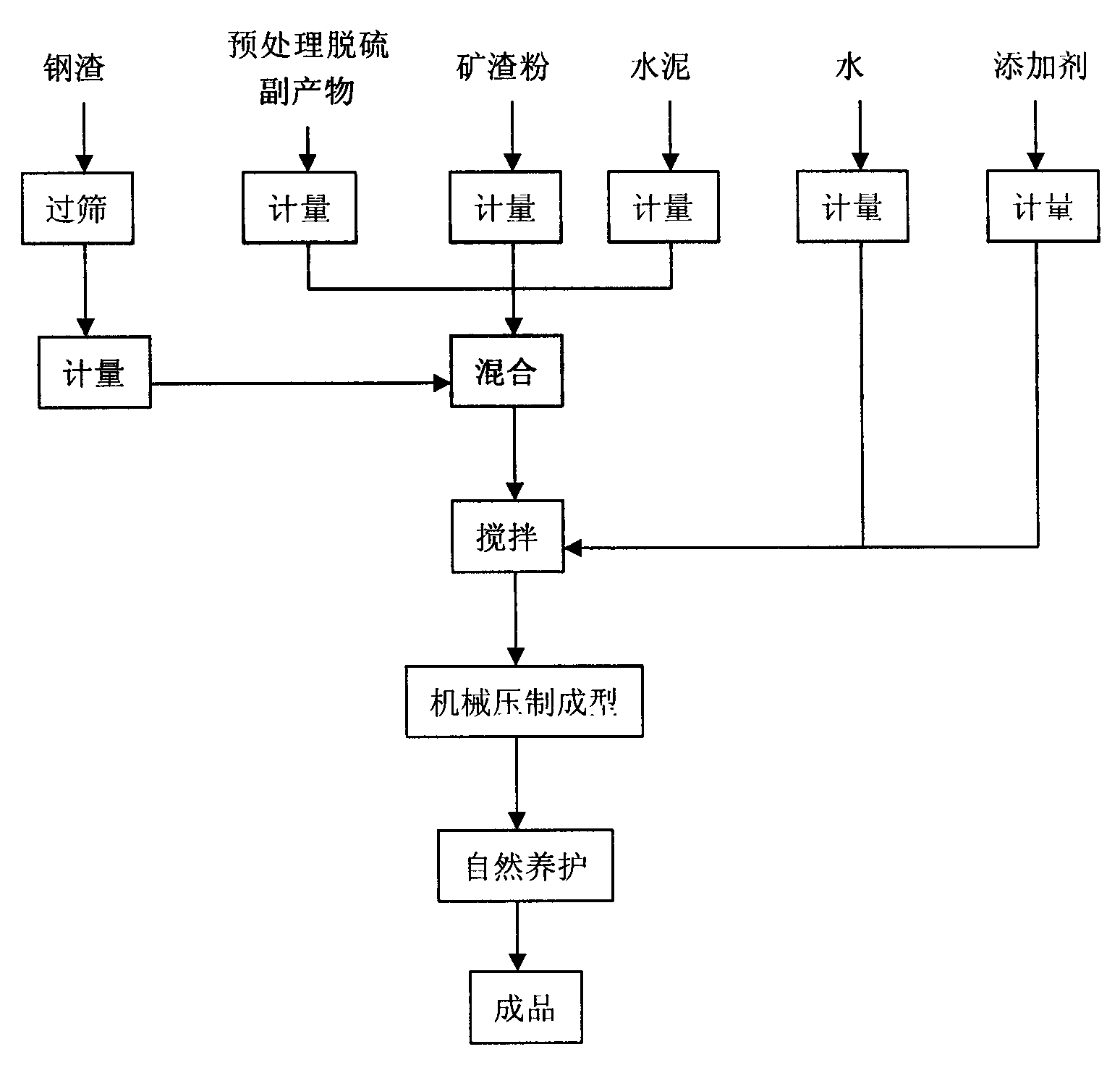

Method used

Image

Examples

Example Embodiment

[0029] Example 1:

[0030] Refer to the national standard "Test Methods for Wall Bricks" GB / T2542-92 for experiment and performance testing.

[0031] The desulfurization by-product is mixed with water to prepare a mixture with a concentration of 60%, and air is blown into it to mix and stir, and the stirring time is 20 minutes. The mud cake after the mixture is filtered by a filter press is naturally dried in the air to a moisture content of 20%.

[0032] The steel slag after the stewing slag treatment is piled up for another 180 days, and it is sieved to take 3mm~10mm granular materials.

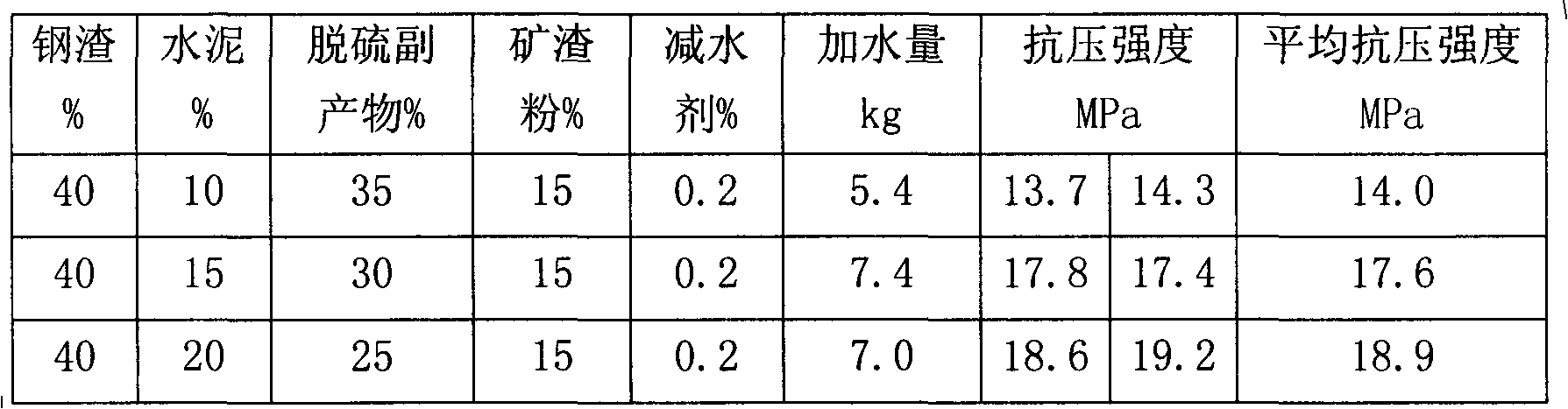

[0033] The materials are measured and mixed according to the material structure shown in Table 1, after stirring for 5 minutes, they are fed into the brick making machine and molded by mechanical compression, and cured under natural conditions for 28 days to obtain the finished double-free bricks.

[0034] Table 1 The influence of desulfurization by-product content on the mechanical properties of no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com