Method for preparing silicon carbide refractory material by taking polycarbosilane as binding agent

A technology of polycarbosilane and refractory materials, which is applied in the field of preparing silicon carbide refractory materials, and can solve problems such as low operating temperature, low grade of silicon carbide refractory materials, and difficulty in preparing thick-sized products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

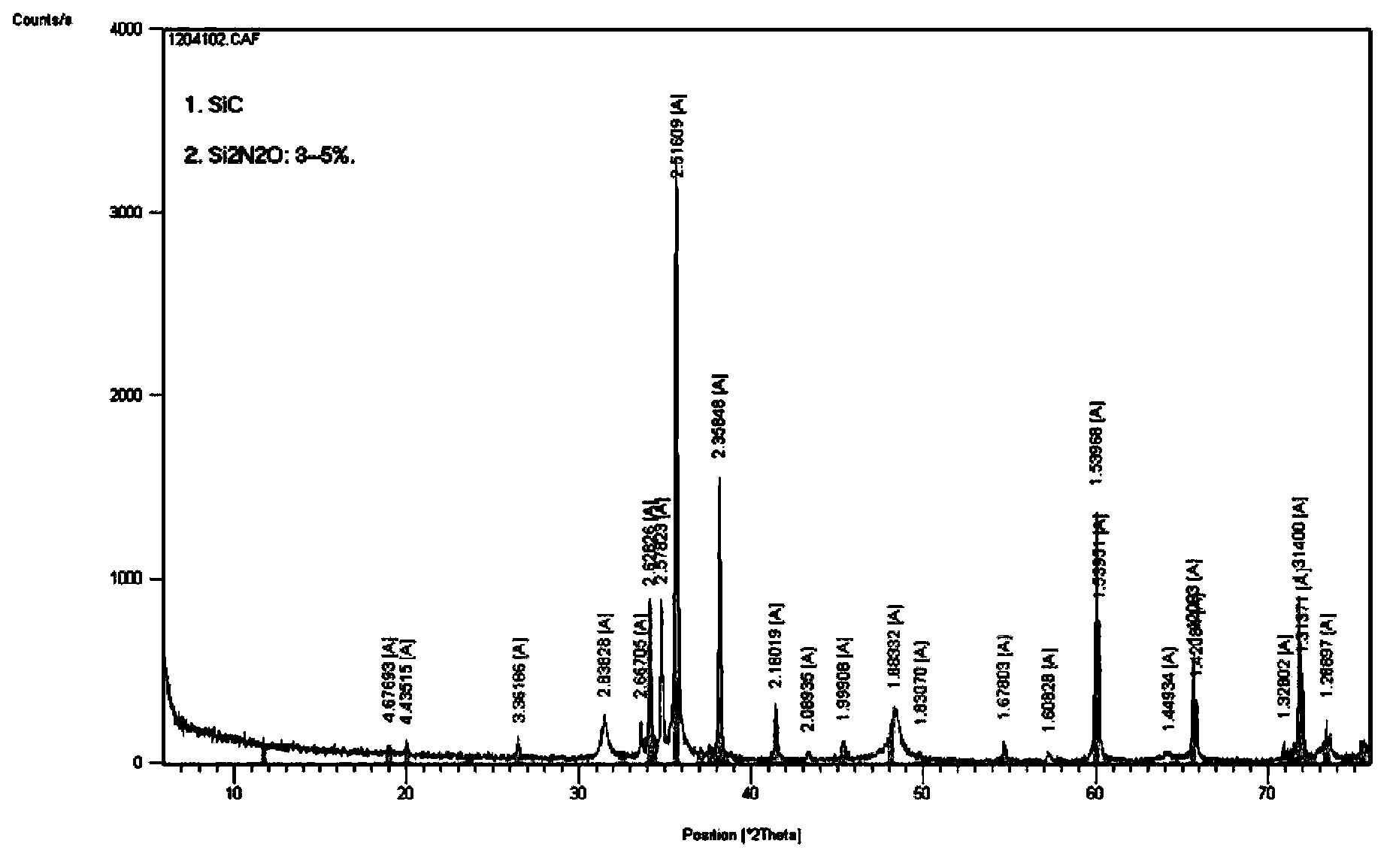

[0032] Polycarbosilane is used as a binder, and silicon carbide particles (particle sizes are 1.43-2.5mm, 0.5-1.43mm, 240 mesh, 2000 mesh) are used to form raw materials, and the mass percentages are 3% and 67% respectively. , 10%, 15%, 5% of the proportion of weighing. The above raw materials were kneaded on a planetary forced mixer for 10 minutes, and the uniformly mixed materials were machine-pressed into a green body, and then the green body was dried in an oven at 100°C for 6 hours. The dried samples were placed in a vacuum furnace and sintered at 1300 °C for 5 h. see figure 1 , the phase composition of the product detected by XRD is mainly silicon carbide phase, a small amount of Si 2 N 2 O is due to slight oxidation of the sample during sintering; see figure 2 , after the precursor is sintered, a large number of fibrous nano-whiskers are formed inside the product; the product body density is 2.55g cm -3 , The flexural strength is 30.6MPa.

Embodiment 2

[0034] Polycarbosilane is used as a binder, and silicon carbide particles (particle sizes are 1.43-2.5mm, 0.5-1.43mm, 240 mesh, 2000 mesh) are used to form raw materials, and the mass percentages are 7% and 60% respectively. , 8%, 16%, 9% weighing. The above raw materials were kneaded on a planetary forced mixer for 20 minutes, and the uniformly mixed materials were pounded to form a green body, and then the green body was dried in an oven at 110°C for 4 hours. The dried samples were placed in an argon atmosphere furnace and sintered at 1500 °C for 1 h. The phase composition of the product detected by XRD is mainly silicon carbide phase, and the volume density of the product is 2.58g cm -3 , The flexural strength is 31.1MPa.

Embodiment 3

[0036] Polycarbosilane is used as a binder, and silicon carbide particles (particle sizes are 1.43-2.5mm, 0.5-1.43mm, 240 mesh, 2000 mesh) are used to form raw materials, and the mass percentages are 10% and 55% respectively. , 5%, 20%, 10% of the proportion of weighing. The above raw materials were kneaded on a planetary forced mixer for 5 minutes, and the uniformly mixed materials were machine-pressed to form a green body, and then the green body was dried in an oven at 80°C for 12 hours. The dried samples were placed in a vacuum furnace and sintered at 1400 °C for 3 h. The phase composition of the product detected by XRD is mainly silicon carbide phase, and the volume density of the product is 2.6g cm-3 , The flexural strength is 35.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Body dense | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Body dense | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com