Method for preparing biodegradable polyesteramide through chain extension

A polyester amide, biodegradable technology, applied in the field of high molecular weight biodegradable polyester amide, can solve the problems of high equipment requirements, high vacuum degree, low content of polyester amide amide bonds, etc., to achieve time-saving reaction level, easy Easy to control and respond to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

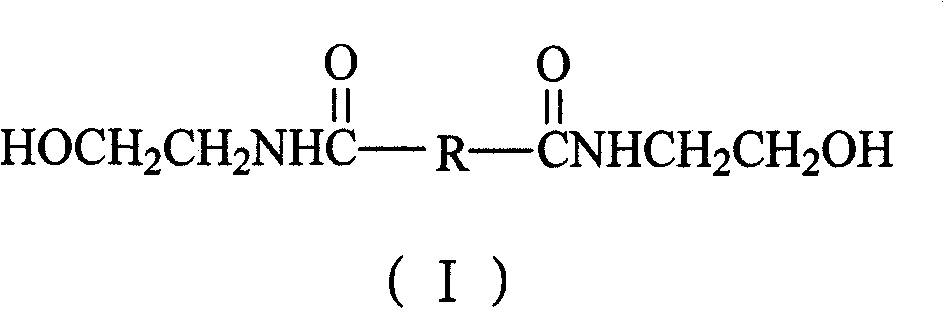

[0052] 1) Preparation of polyester amide prepolymer (PEA): take by weight 50 parts of adipic acid, 27.7 parts of 1,4-butanediol, 8.6 parts of N, N'-two (2-hydroxyethyl ) after mixing terephthalamide and 0.26 parts of dibutyltin oxide, under the protection of nitrogen, the temperature is gradually raised from 160°C to 200°C for polycondensation reaction, after collecting 70-80% of the generated water, use a decompression device instead, First use a water pump to gradually reduce the pressure for 3-4 hours, then use an oil pump to reduce the pressure to 2mmHg, and continue the reaction at a temperature range of 190-210°C for 3-4 hours to obtain an intrinsic viscosity of 0.22dL / g and an acid value of 16.7mgKOH / g, a PEA prepolymer with a hydroxyl value of 6.6mgKOH / g;

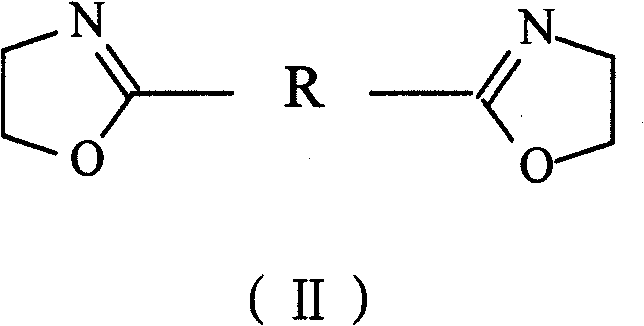

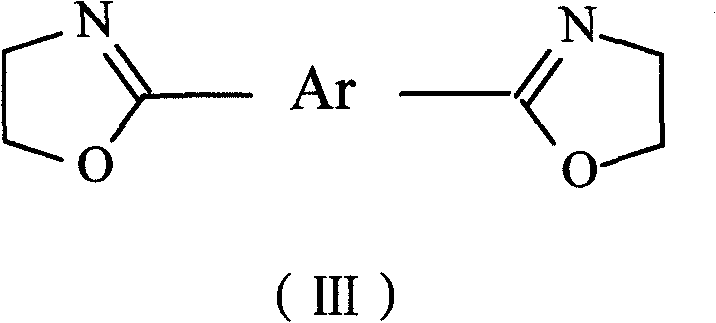

[0053] 2) Weigh 100 parts of the PEA prepolymer prepared in step 1), 2.0 parts of N, N'-terephthaloyl biscaprolactam, 1,4-phenyl-bis(2-oxazoline) in parts by weight 3.5 parts and 0.1 part of p-toluenesulfonic acid...

Embodiment 2

[0055] 1) The consumption of 1,4-butanediol is 29.3 parts, and other conditions are identical with embodiment 1 step 1), synthetic intrinsic viscosity is 0.28dL / g, acid value is 4.3mgKOH / g, hydroxyl value is 24.4mgKOH / g of PEA prepolymer;

[0056] 2) Weigh 100 parts of the PEA prepolymer prepared in step 1), 7.3 parts of N, N'-adipyl biscaprolactam, 1,4-phenyl-bis(2-oxazoline) in parts by weight 0.9 parts and 0.2 parts of p-toluenesulfonic acid were reacted at 200°C under normal pressure for 0.5 hours under the protection of nitrogen, and then reacted in a 3mmHg decompression system for 1 hour. The intrinsic viscosity of the obtained polymer was 1.05dL / g.

Embodiment 3

[0058] 1) The amount of 1,4-butanediol is 26.2 parts, the amount of N, N'-di(2-hydroxyethyl) terephthalamide is 17.1 parts, the catalyst is stannous chloride, and another 0.2 parts are added Phosphorous acid, other conditions are exactly the same as embodiment 1 step 1), and the synthetic intrinsic viscosity is the PEA prepolymer of 0.30dL / g, acid value 14.6mgKOH / g, hydroxyl value 15.0mgKOH / g;

[0059] 2) Weigh 100 parts of PEA prepolymer prepared in step 1), 4.6 parts of N, N'-adipyl biscaprolactam, and 3.1 parts of 1,4-phenyl-bis(2-oxazoline) in parts by weight , 0.1 part of p-toluenesulfonic acid, reacted at 220°C under normal pressure for 0.5 hours under the protection of nitrogen, and then reacted in a 5mmHg reduced pressure system for 2.5 hours. The intrinsic viscosity of the obtained polymer was 0.73dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com