Continuous mining technique for thin coal layer of opencast coal mine

A technology of open-pit coal mine and process method, which is applied in open-pit mine mining, ground mining, earth square drilling, etc., and can solve problems such as low efficiency, difficult centralized crushing, and increased mining costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing:

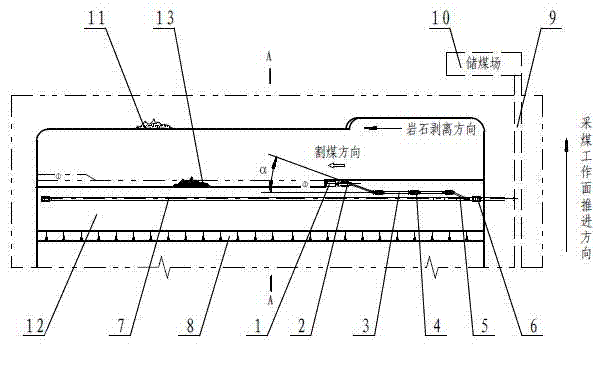

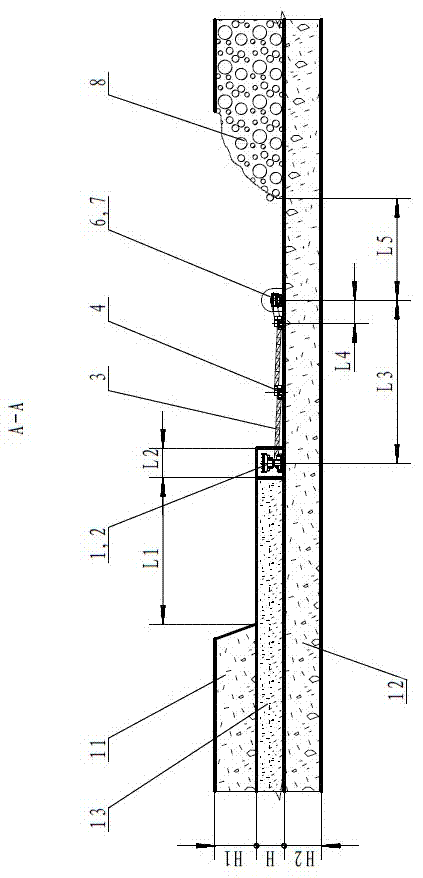

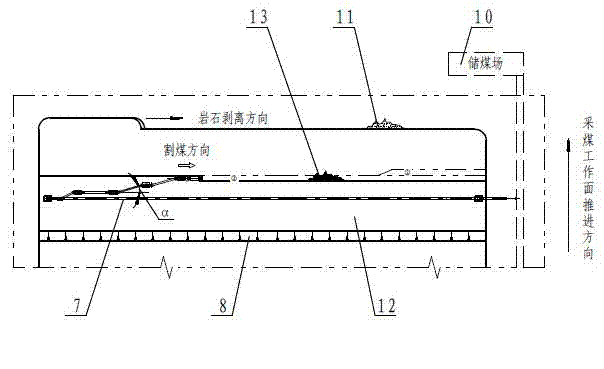

[0057] As shown in Figures 1, 2, 3, and 4, they are the layout diagrams of the first, second, third, and Nth mining widths. The equipment layout of each mining width is the same, which is the working cycle of continuous mining equipment. After the excavation is completed, enter the next step. The equipment layout is carried out according to the method of excavation-crushing-transferring-transportation. The position and connection of each equipment must be correct and the installation should be firm.

[0058] The layout of the mining area is as follows: the lower part of the upper rock layer 11 is the coal seam 13, the lower part of the coal seam 13 is the lower rock layer 12, the working face belt conveyor 7 is installed on the lower rock layer 12, and the open-pit coal mine continuous mining is arranged successively at the starting point of the coal cutting direction. Coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com