Halogen -free flame-proof ABS resin and its preparing method

A kind of resin and epoxy resin technology, applied in the field of flame retardant resin, can solve the problems of difficult flame retardant plastic flame retardant modification, poor flame retardant efficiency, no flame retardant, etc., to achieve stable product quality and high production efficiency , Good effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

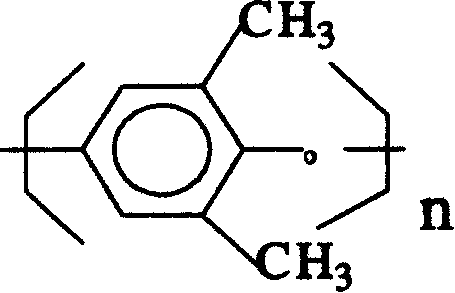

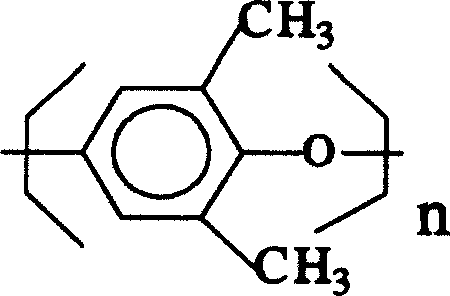

Image

Examples

Embodiment 1

[0021] The components and parts by weight of the novel halogen-free flame-retardant ABS resin of the present invention are shown in Table 1, and the physical properties are shown in Table 2. Among them, the ABS resin is 8391 of DOW Company, the PPE is S202A of Asahi Kasei Company, the TPP is the product of Dahachi Chemical Company, the epoxy resin is E-51 of Shanghai Resin Co., Ltd., and the antioxidant is 1010 of ciba refinement.

[0022] The preparation method is as follows: the first step is to mix ABS resin, polyphenylene ether, phosphonate, epoxy resin, light and heat stabilizer and other components uniformly through high-speed stirring; the second step is to feed the above mixture The feeder is fed into the extruder, fully melted and compounded under the conveying and shearing action of the screw, and then extruded through the machine head, drawn, cooled, pelletized, and finally packaged.

[0023] The aspect ratio of the twin-screw extruder used in the preparation method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notch shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com