High-heat-resistance high-toughness ABS (acrylonitrile-butadiene-styrene) resin and preparation method thereof

An ABS resin, high-toughness technology, applied in the polymer field, can solve the problems of the heat-resistant temperature of the parts not meeting the requirements, the impact toughness is reduced, etc., and achieve the effects of stable product quality, improved heat-resistant temperature and toughness, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of ABS resin with high heat resistance and high toughness is:

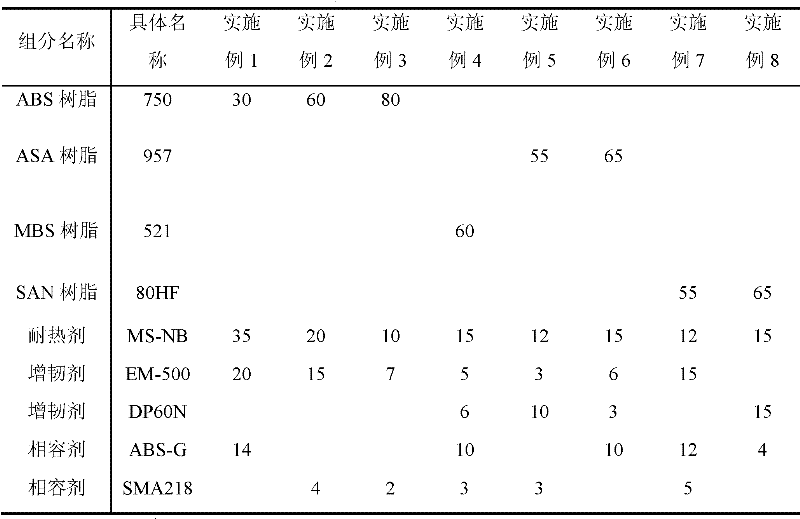

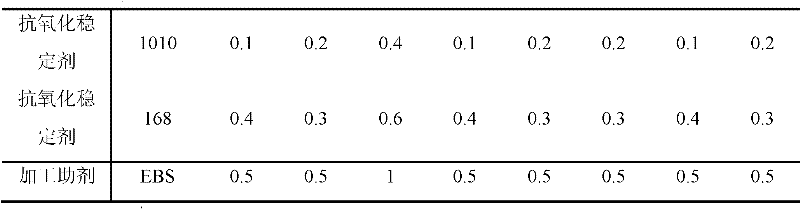

[0043] (1) take ABS resin, toughening agent, compatibilizer, antioxidant and processing aid by the proportioning in table 2;

[0044] (2) Put each component in the step (1) into a high-speed mixer, and the high-speed mixer speed is 50 rpm / min and fully mixed for 5 minutes;

[0045] (3) With a metering and conveying device, the mixed material in step (2) is sent into the twin-screw extruder, and fully mixed through the shearing action of the screw, wherein the long diameter of the twin-screw extruder is 40 : 1, the screw speed is 150 rpm, the working temperature range of the twin-screw extrusion is 180°C in the first zone, 200°C in the second zone, 215°C in the third zone, 215°C in the fourth zone, 220°C in the head, and stay for 1 to 2 minutes , after extrusion, drawing, cooling, pelletizing; packaging into finished products.

Embodiment 2

[0047] (1) take ABS resin, toughening agent, compatibilizer, antioxidant and processing aid by the proportioning in table 2;

[0048] (2) Put each component in the step (1) into a high-speed mixer, and the high-speed mixer speed is 80 rpm / min and fully mixed for 4 minutes;

[0049] (3) With a metering and conveying device, the mixed material in step (2) is sent into the twin-screw extruder, and fully mixed through the shearing action of the screw, wherein the long diameter of the twin-screw extruder is 40 : 1, the screw speed is 300 rpm, the working temperature range of the twin-screw extrusion is 180°C for the first zone, 195°C for the second zone, 205°C for the third zone, 215°C for the fourth zone, 210°C for the head, and stay for 1 to 2 minutes , after extrusion, drawing, cooling, pelletizing; packaging into finished products.

Embodiment 3

[0051] (1) take ABS resin, toughening agent, compatibilizer, antioxidant and processing aid by the proportioning in table 2;

[0052] (2) Put each component in the step (1) into a high-speed mixer, and the speed of the high-speed mixer is 120 rpm / min and fully mixed for 4 minutes;

[0053] (3) With a metering and conveying device, the mixed material in step (2) is sent into the twin-screw extruder, through the shearing action of the screw, fully mixed, wherein the long diameter of the twin-screw extruder is 42 : 1, the screw speed is 350 rpm, the working temperature range of twin-screw extrusion is 180°C in the first zone, 195°C in the second zone, 200°C in the third zone, 210°C in the fourth zone, 205°C in the head, and stay for 1 to 2 minutes , after extrusion, drawing, cooling, pelletizing; packaging into finished products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com