Low fog value polyester composition and preparation thereof

A technology of composition and fog value, which is applied in the field of polymer material preparation, can solve the problems of fogging of transparent lampshade materials, affecting the surface effect of metal plating layer, affecting the long-term use and appearance of car lights, etc., to improve the processing and molding efficiency, excellent Dimensional stability and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] formula:

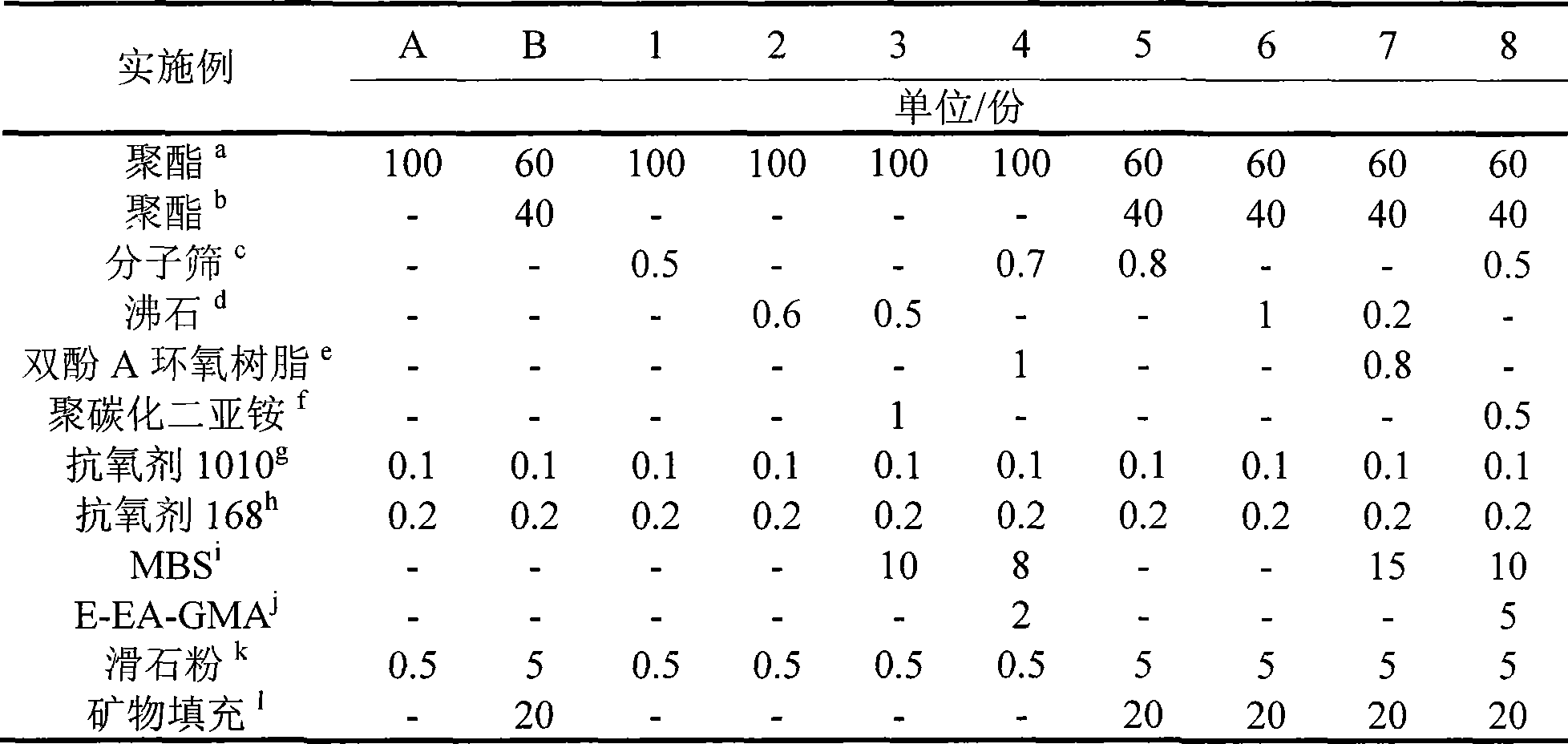

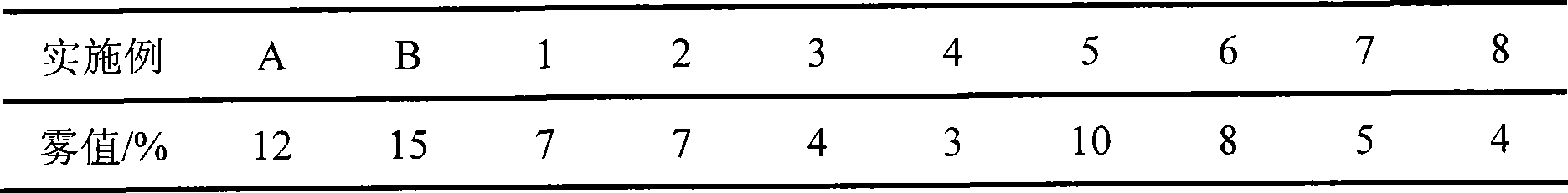

[0061] The formulations of Examples A and B and Examples 1-8 are shown in Table 1.

[0062] Table 1

[0063]

[0064] Among them: a is polybutylene terephthalate, Ultradur B4500 of Basf; b is polyethylene terephthalate, PET of Shanghai Petrochemical; c is 4A molecular sieve of Shanghai Sinopharm Reagent; d is Shanghai Sinopharm Reagent E is Shell’s EP1001; f is RheinChmie’s Stabaxol P200; g is CIBA’s IG-1010; h is CIBA’s IG-168; i is Rohm&Hass’s Paraloid EXL-2691A; j is Atfona’s Lotader AX8900; k is 2500 mesh talcum powder; 1 is Nyad 5000 from Nyco. Processing technology:

[0065] High-speed mixer: rotating speed 650rpm, time 30min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com