High-fluidity polyester composition and preparation method

A composition and high-flow technology, applied in the field of polymer composition and its preparation, can solve the problems of excessive polyol addition, high volatile matter, unfavorable industrial production and use, etc., and achieve stable product quality and high production efficiency , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0035] A preparation method of high flow polyester composition, the method may further comprise the steps:

[0036] (1) prepare raw materials according to the component and content in table 1, wherein a is polybutylene terephthalate, the Ultradur B4500 of Basf; b is polyethylene terephthalate, the PET of Shanghai Petrochemical; c d is CIBA IG-1010; e is CIBA IG-168; f is Rohm&Hass' Paraloid EXL-2691A; g is Atfona's Lotader AX8900; h is 2500 mesh talcum powder ; i is 536 of JuShi.

[0037] (2) Put the thermoplastic polyester, flow accelerator, toughening agent and antioxidant in the high-speed mixer according to the above ratio, control the rotating speed at 650rpm, and the time is 30min. After stirring and mixing evenly, the obtained mixture is fed by the main It is fed into the twin-screw extruder, and then the inorganic reinforcing filler is fed into the extruder through side feeding, extruded and pelletized to obtain the product. The screw aspect ratio of the twin-screw e...

Embodiment 6

[0056] A preparation method of high flow polyester composition, the method may further comprise the steps:

[0057] (1) Prepare materials according to the following components and contents:

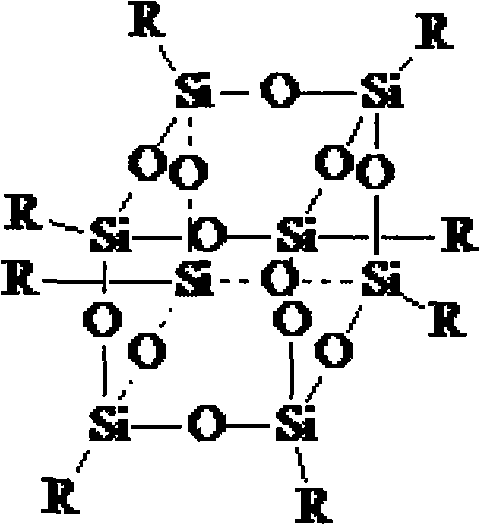

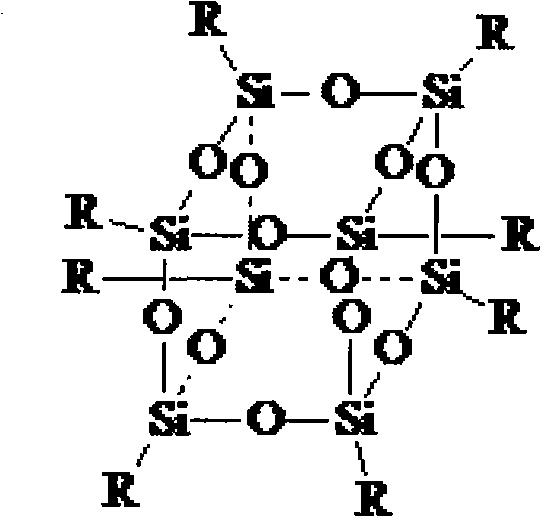

[0058] 24kg thermoplastic polyester, 0.1kg flow promoter, 1kg antioxidant, 15kg toughening agent, wherein the thermoplastic polyester is polyethylene terephthalate (PET), and the intrinsic viscosity when measuring o-chlorophenol solution at 25°C is 0.52; the flow enhancer is octaphenyl clathrate silsesquioxane, and its structure is as follows:

[0059]

[0060] Wherein R is a methyl group; the antioxidant is triphenyl phosphate (TPP); the toughening agent is acrylonitrile-butadiene-acrylate copolymer (ASA).

[0061] (2) Stir and mix thermoplastic polyester, flow accelerator, toughening agent and antioxidant according to the above ratio through a high-speed mixer, and send the main feed into the twin-screw extruder to control the length of the twin-screw extruder. The diameter ratio i...

Embodiment 7

[0063] A preparation method of high flow polyester composition, the method may further comprise the steps:

[0064] (1) Prepare materials according to the following components and contents:

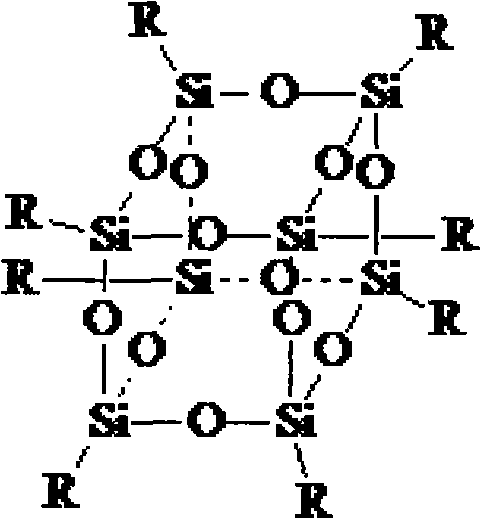

[0065] 100kg of thermoplastic polyester, 5kg of flow promoter, 0.1kg of antioxidant, 50kg of inorganic reinforcing material, wherein the thermoplastic polyester is polybutylene terephthalate (PBT), and the intrinsic viscosity of o-chlorophenol solution is measured at 25°C is 0.45; the flow enhancer is octaphenyl clathrate silsesquioxane, and the structure is as follows:

[0066]

[0067] Wherein R is an epoxy group; the antioxidant is tetrakis[β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester; the inorganic reinforcing material is talcum powder.

[0068] (2) Stir and mix thermoplastic polyester, flow promoter and antioxidant according to the above ratio through a high-speed mixer, and send it into the twin-screw extruder from the main feed, and then add inorganic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com