Hydrophobic silicon dioxide/polyimide aerogel composite material and preparation method

A polyimide wet gel and silica technology, applied in the field of high-performance porous materials, can solve the problems of molecular weight reduction, flammability, difficulty in realizing airgel scale, rapid and efficient preparation, etc., and achieve improved hydrophobicity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

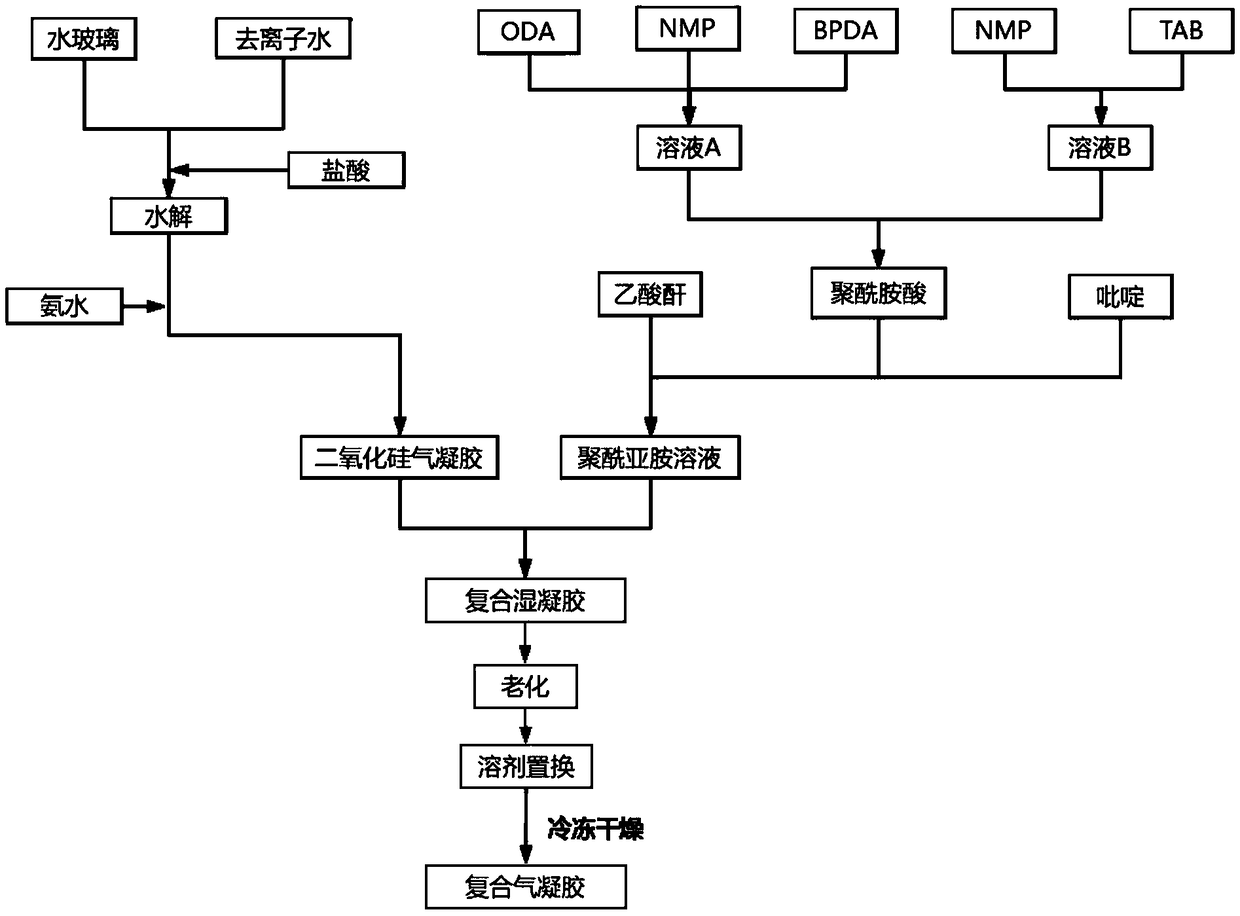

[0082] The present invention also provides a preparation method of silica / polyimide airgel composite material, comprising the following steps:

[0083] 1) After the polyimide wet gel mixture mixed with silica airgel powder is left to stand, it is then placed in an organic solvent for replacement to obtain a substituted polyimide composite wet gel;

[0084] 2) Submerging the substituted polyimide composite wet gel obtained in the above steps in tert-butanol and / or cyclohexane for further replacement to obtain a semi-finished product;

[0085] 3) After the semi-finished product obtained in the above steps is freeze-dried, a silica / polyimide airgel composite material is obtained.

[0086] The selection, ratio and parameters of raw materials or products in the above-mentioned preparation method of the present invention, and corresponding optimization principles etc., if not specified, are similar to the selection of raw materials in the aforementioned silica / polyimide airgel compo...

Embodiment 1

[0184] Silica airgel

[0185] Take water=30ml and water glass=10ml and mix and stir in a beaker to obtain solution A. Take concentrated HCl=5ml, add solution A into the HCl solution for hydrolysis reaction, slow down the speed and test the pH when adding half of it, add a pH regulator, continue to add solution A (color from yellow to transparent, pH 1~2→5~6 ),gel.

[0186] Grind the wet gel, add HMDSO = 80Ml, n-hexane = 20ml, then add 5ml of concentrated hydrochloric acid, stir and separate layers to indicate that the modification is complete.

[0187] see figure 2 , figure 2 Appearance diagram of the layered hydrophobically modified silica airgel prepared for the present invention.

[0188] The airgel powder is obtained after the upper layer is taken and dried.

[0189] composite airgel

[0190] First, dissolve 4,4'-aminodiphenyl ether (ODA, 8mmol) in the solvent 1-methyl-2-pyrrolidone (NMP, 33ml) and stir until it is completely dissolved, then add 3,3',4,4'-biphenyl ...

Embodiment 2 and 3

[0201] Referring to the above method, composite materials with silica airgel powder addition ratios of 10% and 20% were prepared respectively.

[0202] see Figure 4 , Figure 4 Scanning electron micrographs of hydrophobic silica / polyimide airgel composites with different ratios prepared for the examples of the present invention.

[0203] Performance tests were performed on the hydrophobic silica / polyimide airgel composite materials prepared in Examples 1-3 of the present invention.

[0204] see Figure 5 , Figure 5 The mechanical property curves of the hydrophobic silica / polyimide airgel composite material with different silica airgel doping amounts prepared in Example 1 of the present invention.

[0205] Depend on Figure 5 It can be seen that, according to the compressive stress-strain curve, as the compressive strain increases, the compressive stress continues to increase. The whole process is divided into three stages, the first stage is the contact stage, the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com