Base metal for high-toughness clad steel plate giving weld with excellent toughness, and process for producing clad steel plate

A technology of composite steel plate and welded part, which is applied in the direction of manufacturing tools, welding equipment, chemical instruments and methods, etc., can solve the problems of increased manufacturing cost and achieve the effect of excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

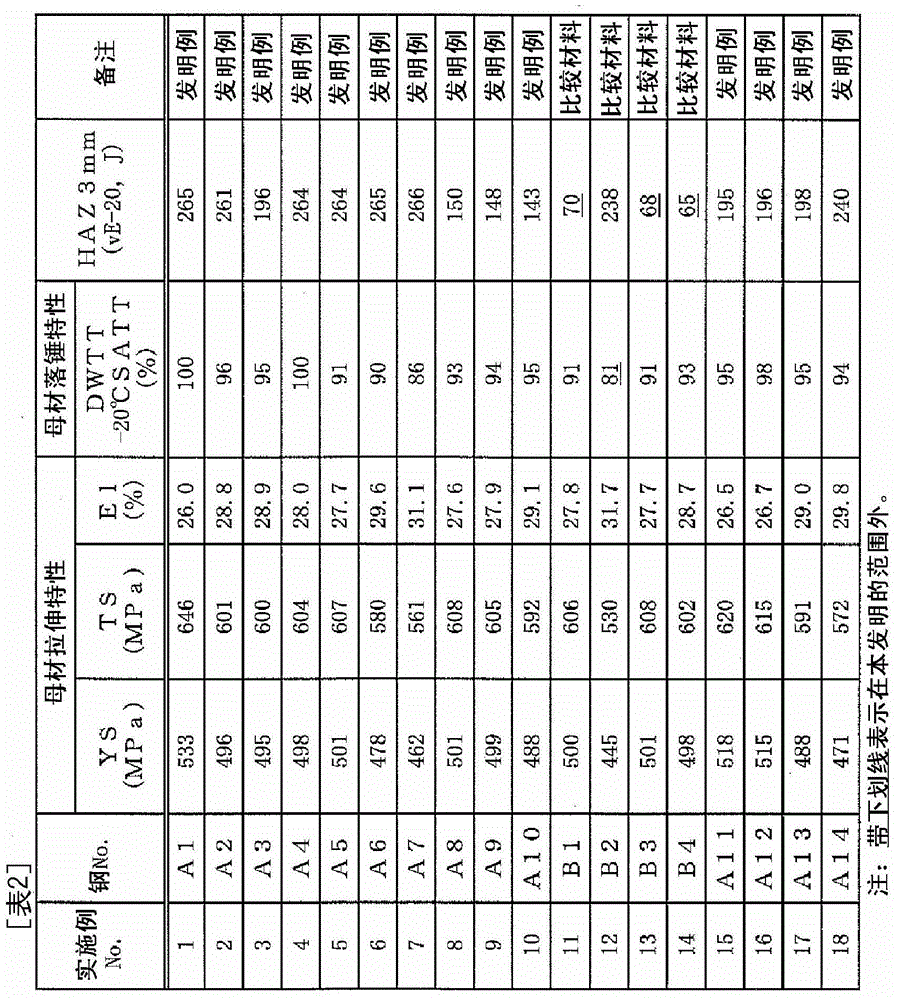

[0089] Hereinafter, examples of the present invention will be described while comparing with comparative examples. Here, the evaluation of weld toughness was performed by a Charpy test. The notch position of the Charpy test piece was set at a position shifted by 3 mm (HAZ 3 mm) from the joint portion which is the boundary between the weld metal and the base metal to the base metal side. Carried out at a test temperature of -20°C. In the present invention, the absorbed energy (vE-20° C.) at -20° C. is 100 J or more as excellent in toughness.

[0090] In addition, the toughness of the base material was evaluated by a DWTT test (drop weight characteristic) at -20°C. In the present invention, the ductile fracture ratio in the DWTT test at -20°C is 85% or more, which means that the toughness of the base material is excellent.

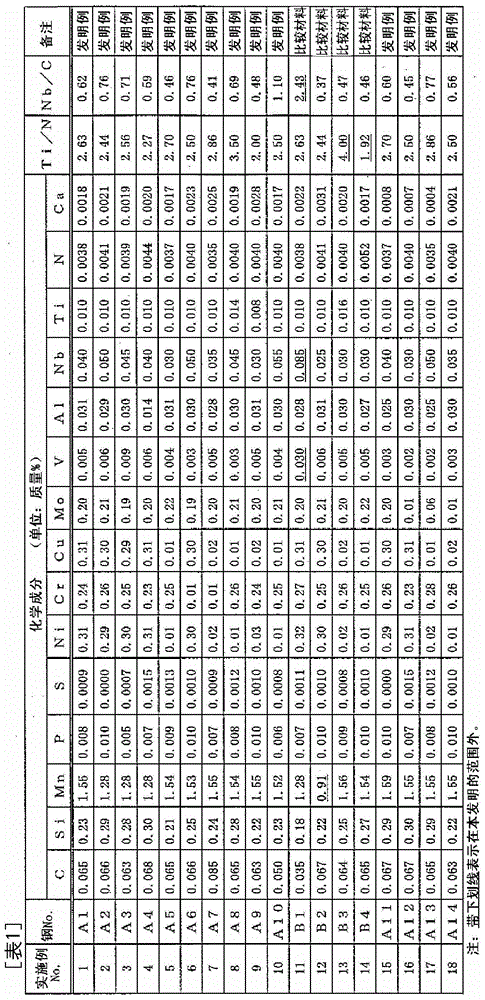

[0091] Using base metals and Alloy625 having the chemical compositions shown in Table 1, clad steel sheets were produced. Regarding the manufacturing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com