Evaluation method of abnormal fracture in drop weight tear test of steel pipe

A technology of drop weight tearing test and evaluation method, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of no recognized and reliable judgment criteria, and solve the problem of judging abnormal fractures Effect

Active Publication Date: 2012-05-23

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But so far, there is still no recognized and reliable criterion for judging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

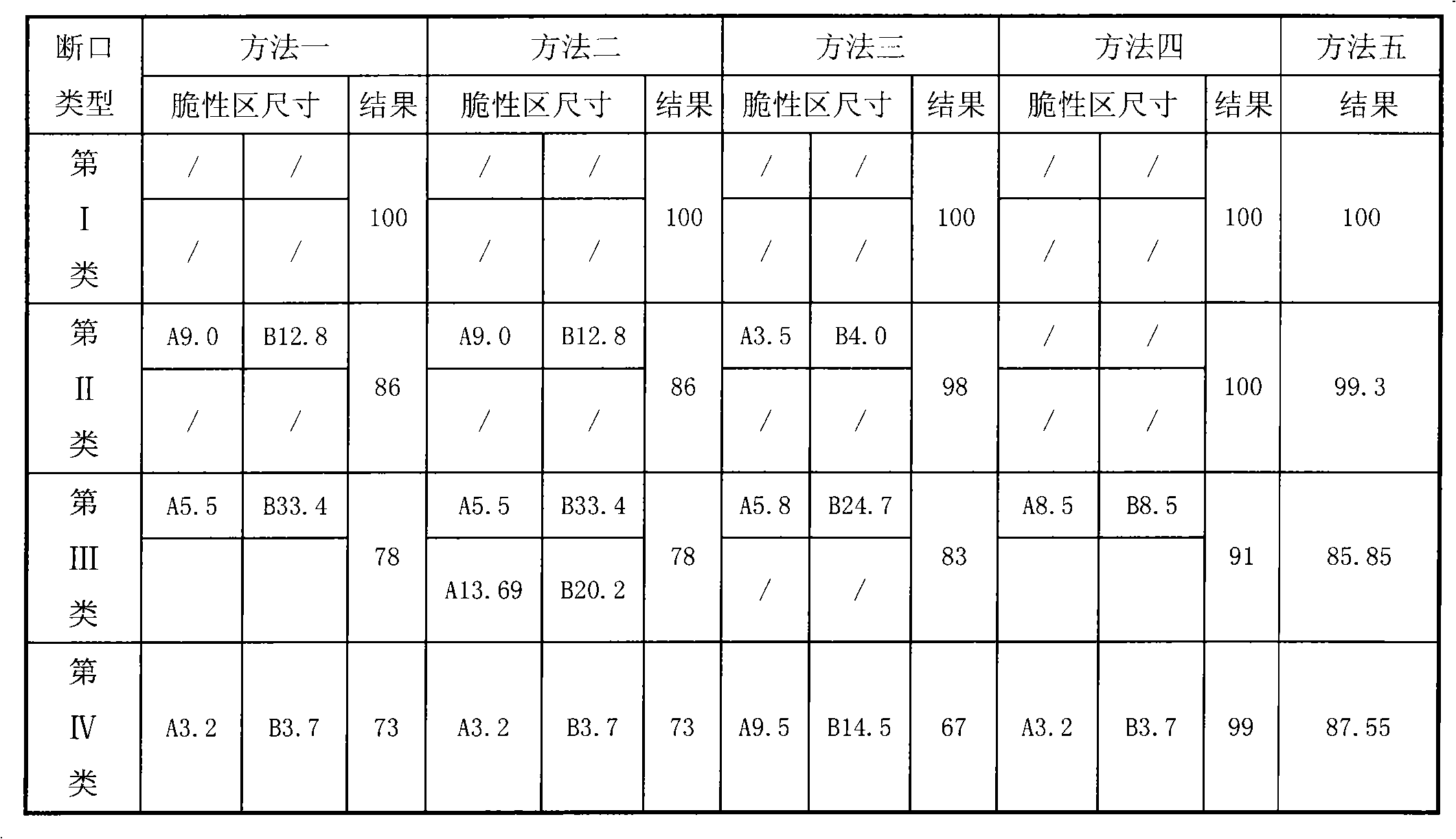

[0028] According to the above five methods, four typical abnormal fractures were judged, and the results are shown in Table 1.

[0029] Table 1 The actual fracture evaluation results (%)

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an evaluation method of an abnormal fracture in a drop weight tear test of a steel pipe; according to the distribution characteristics of brittle zones in the abnormal fracture, the abnormal fracture is classified into four types: in a first type of abnormal brittle fracture, the brittle zones are distributed within one 1 wall thickness on a hammering side; in a second type of abnormal brittle fracture, the brittle zones are on the hammering side and are distributed out of one wall thickness; in a third type of abnormal brittle fracture, the brittle zones are distributed in the middle part of fracture ligament, and exceed the centerline of the fracture ligament from the hammering side; and in a fourth type of abnormal brittle fracture, brittle zones appear earlier, and the nearest distance of the zones from the fracture is less than 1 wall thickness. The invention provides the evaluation methods of fracture classification and the abnormal fracture of the drop weight tear test of high-grade large-aperture high-pressure gas transmission pipeline steel and the steel pipe, solves the difficult problem of abnormal fracture evaluation, and meets the needs of quality control and acceptance evaluation of the high-grade pipeline steel and steep pipe.

Description

technical field [0001] The invention relates to a fracture evaluation method of a high-grade pipeline steel and a steel pipe in a drop weight tearing test, and in particular proposes an evaluation method for an abnormal fracture, which is used for quality control and acceptance evaluation of a high-grade pipeline steel and steel pipe. Background technique [0002] In order to improve the limitations of the Charpy impact test in evaluating the toughness and ductile-brittle transition tendency of materials, a method for the toughness and ductile-brittle transition tendency of materials by the full-wall drop weight tear test (DWTT) has been developed internationally. And established the standard of drop weight tearing test method for pipeline steel and ship plate, which has been widely used in its quality control and acceptance evaluation. [0003] However, with the development and application of high-strength pipeline steel, abnormal fracture problems often appear in DWTT expe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/303G01N3/34

Inventor 陈宏达冯耀荣郭生武柴惠芬

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com