Characterization method for stress softening and instantaneous residual strain in elastomer tearing mode

A residual strain, elastic body technology, applied in the direction of strength characteristics, testing material strength using applied repetitive force/pulsation force, instrumentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

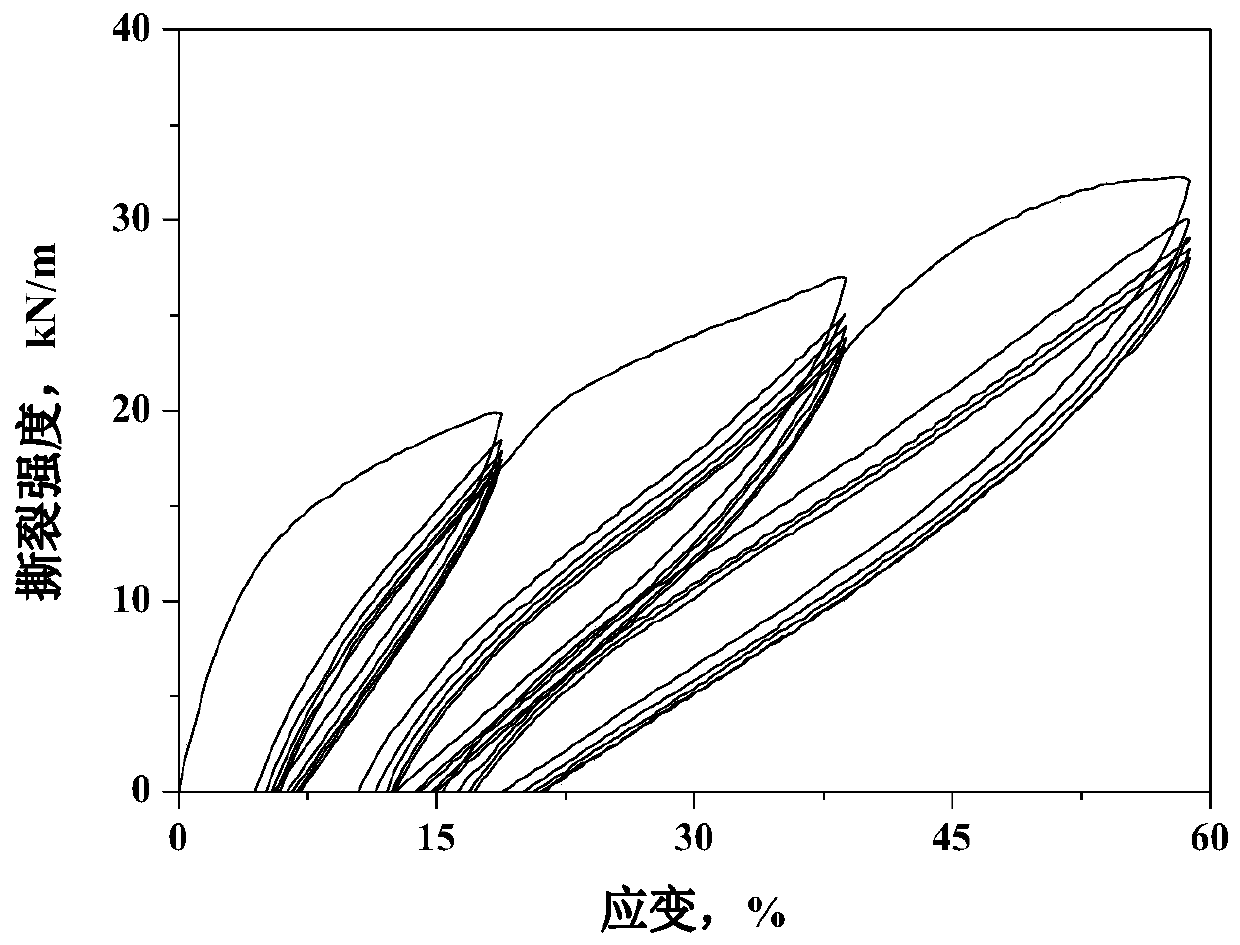

[0018] Example 1: Characterization of Uniaxial Cyclic Tear Stress Softening and Transient Residual Strain of SBS Thermoplastic Elastomer

[0019] Prepare the tear sample of SBS thermoplastic elastomer by molding method, the thickness of the sample is 1.77mm, the SBS brand is YH-792, the styrene content is 40%, the sample should not have air bubbles, impurities and damage, and the initial distance between the marking lines of the sample is 50mm . The GT-TCS-2000 universal material testing machine was used to carry out the uniaxial cyclic tear test on the sample, and the tear strains were 20%, 40% and 60%, respectively. The tear sample and relaxation test in the uniaxial cyclic tear process The speed of the sample is 50mm / min; the sample is continuously torn for 5 times under the tear strain set by the program; the tear strength-strain curve is shown in figure 1 .

[0020] according to figure 1 The quantitative data of uniaxial cyclic tear stress softening and instantaneous r...

Embodiment 2

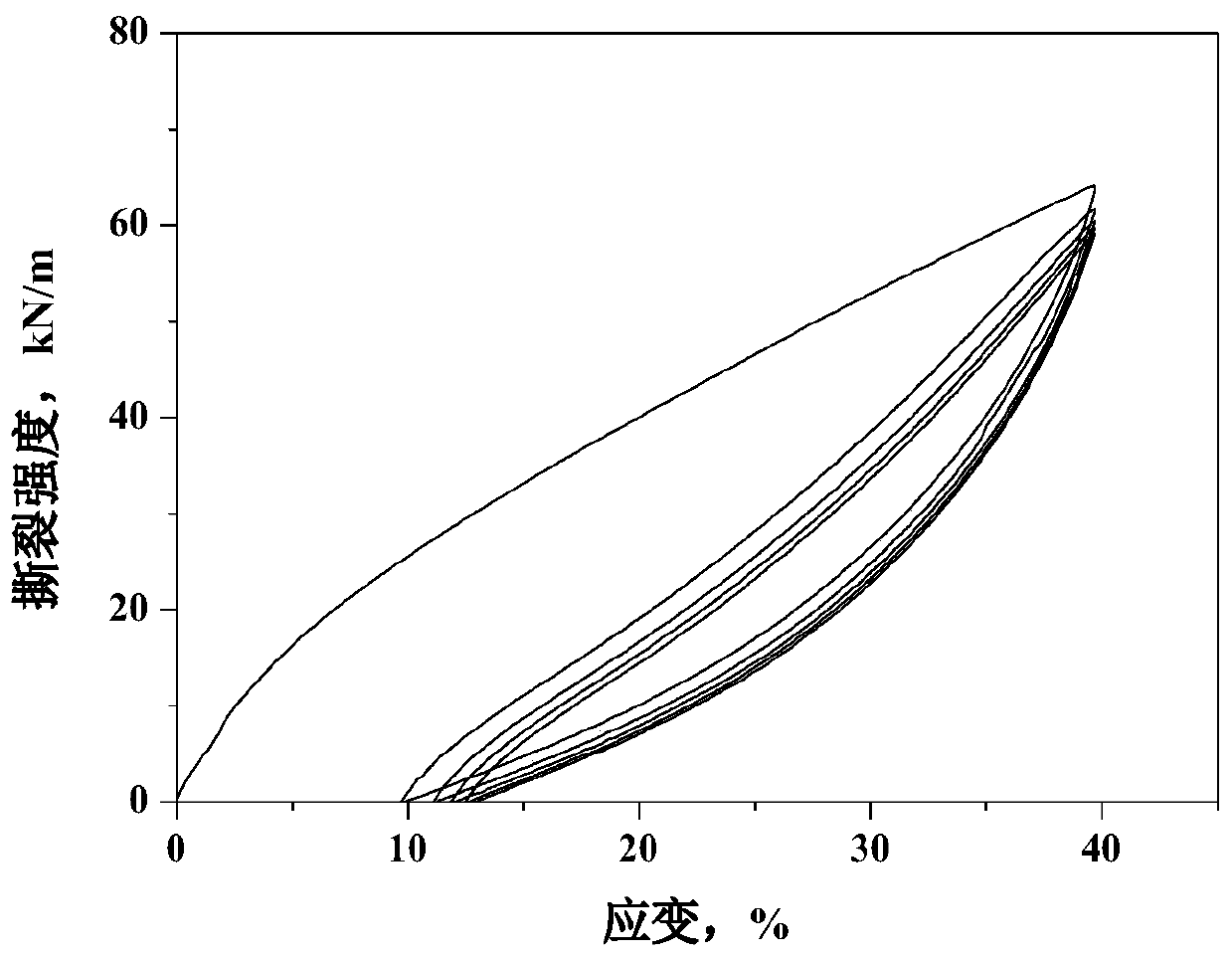

[0021] Example 2: Characterization of uniaxial cyclic tear stress softening and transient residual strain of PP / EPDM thermoplastic vulcanizate

[0022] The tear sample of PP / EPDM thermoplastic vulcanizate was prepared by molding method. The thickness of the sample was 2.12mm. It was prepared by dynamic vulcanization of sulfur vulcanization system. There should be air bubbles, impurities and damage, and the initial distance between the marking lines of the sample is 50mm. Adopt GT-TCS-2000 universal material testing machine to carry out uniaxial cyclic tear test to the sample, the tear strain is 40%, and the speed of the tearing sample and the relaxation sample in the uniaxial cyclic tearing process are both 50mm / min; The sample is continuously torn for 5 times under the tear strain set by the program; the tear strength-strain curve is shown in figure 2 .

[0023] according to figure 2 The quantitative data of uniaxial cyclic tear stress softening and instantaneous residu...

Embodiment 3

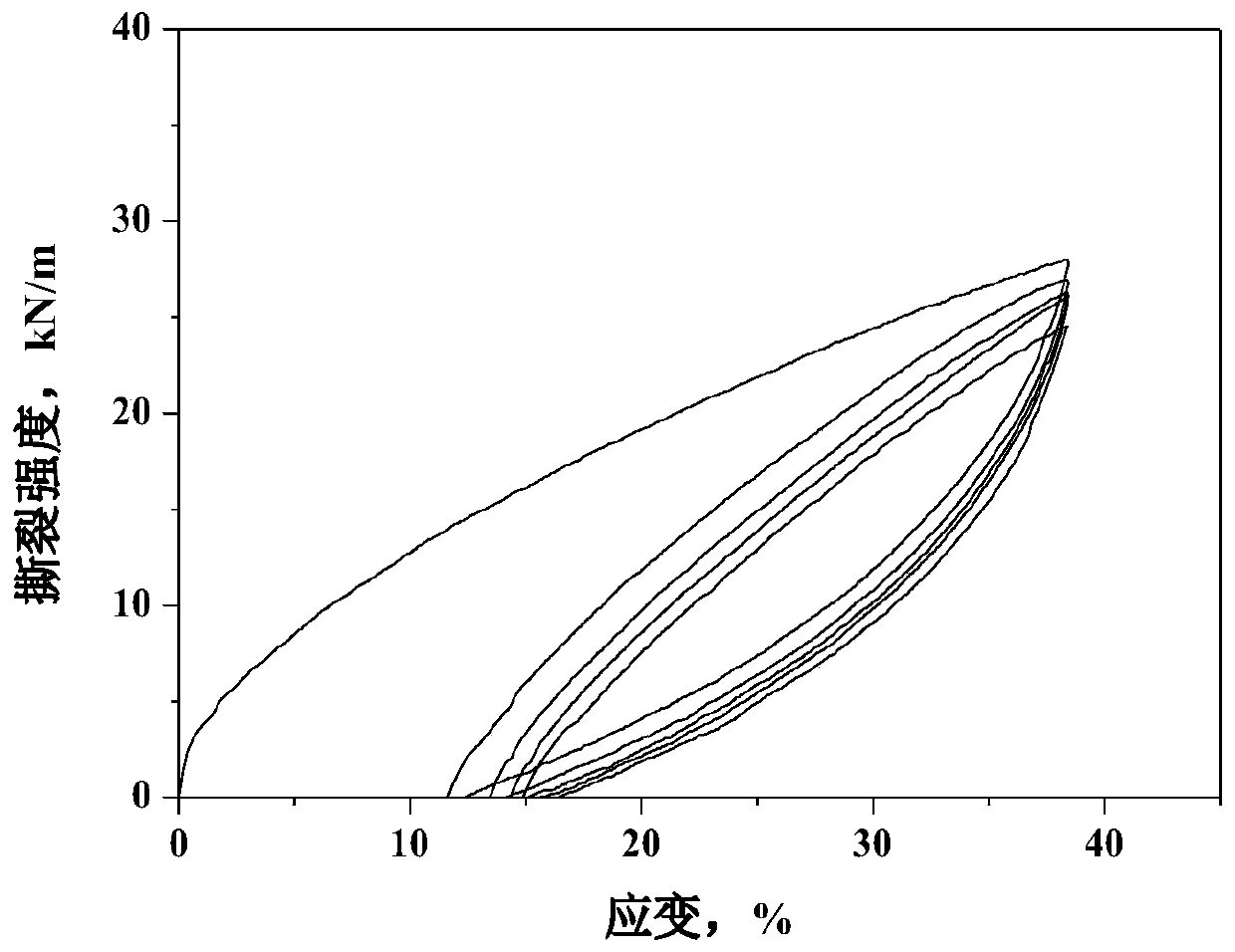

[0024] Example 3: Characterization of uniaxial cyclic tear stress softening and transient residual strain of EAA / NBR thermoplastic vulcanizate

[0025] The tear sample of EAA / NBR thermoplastic vulcanizate was prepared by molding method. The thickness of the sample was 1.71mm. It was prepared by dynamic vulcanization of peroxide vulcanization system. The sample should not have air bubbles, impurities and damage, and the initial distance between the marking lines of the sample is 50mm. Adopt GT-TCS-2000 universal material testing machine to carry out uniaxial cyclic tear test to the sample, the tear strain is 40%, and the speed of the tearing sample and the relaxation sample in the uniaxial cyclic tearing process are both 50mm / min; The sample is continuously torn for 5 times under the tear strain set by the program; the tear strength-strain curve is shown in image 3 .

[0026] according to image 3 The quantitative data of uniaxial cyclic tear stress softening and instantan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com