Method of calculating arrested toughness of pipeline by full dimensional bursting test of natural gas pipeline

A natural gas pipeline and blasting test technology, applied in the field of pipeline hazard protection, can solve the problems of waste of materials, difficulty in welding, inability to accurately determine the crack arrest toughness of pipelines, etc., and achieve the effects of saving pipeline production and construction costs, good application value, and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

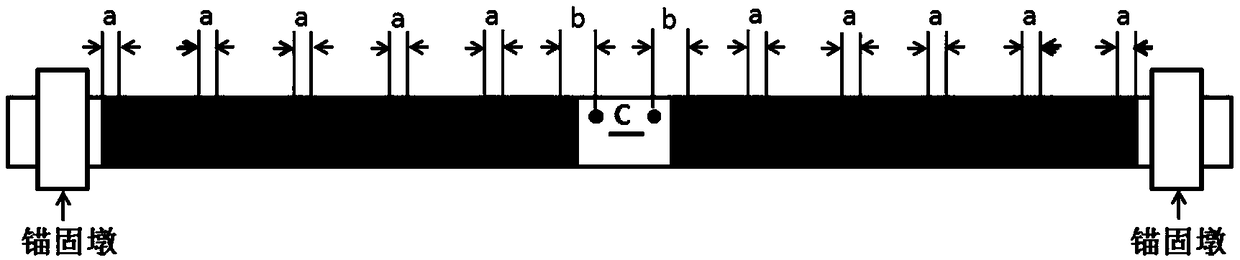

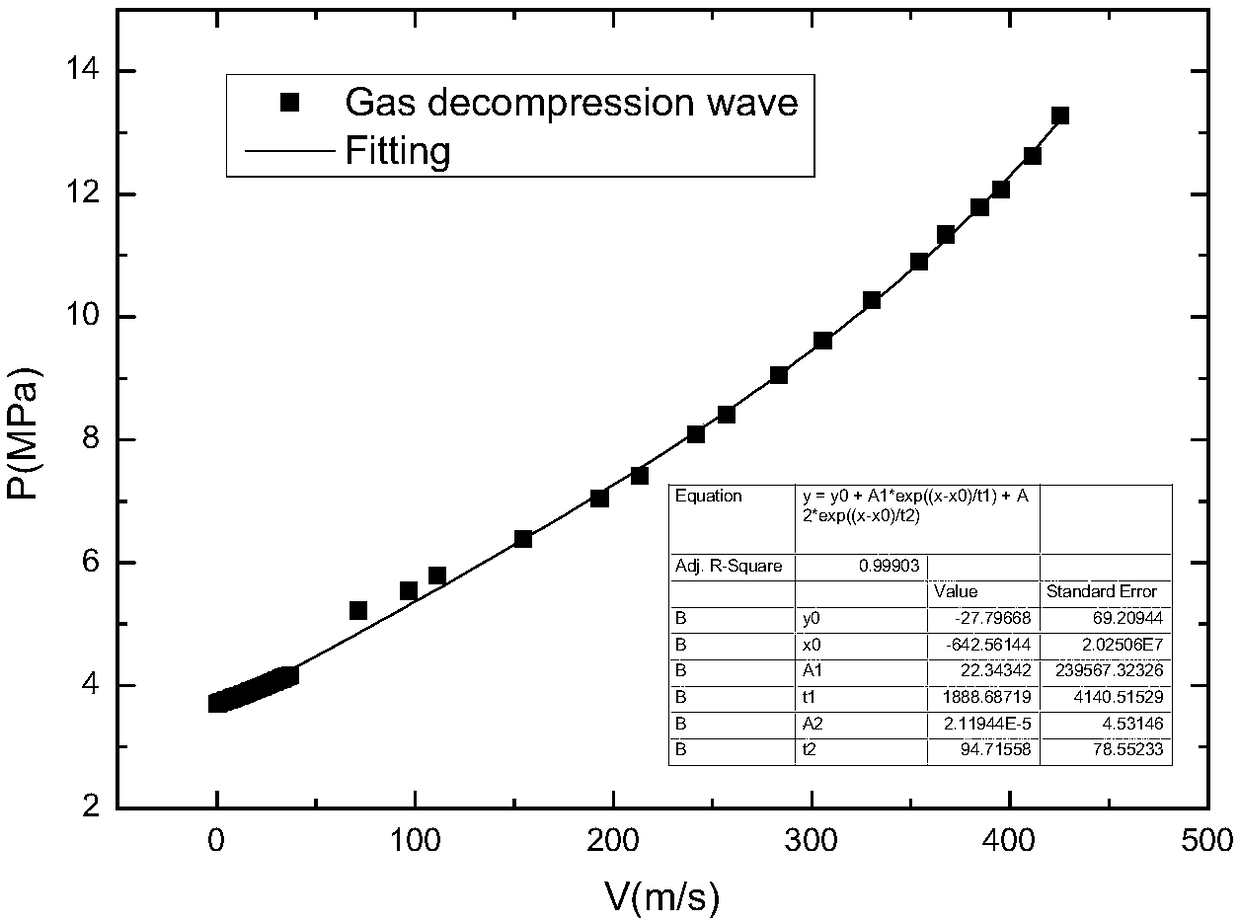

[0040] The test steel pipe is a spiral seam welded pipe with an outer diameter of 1422mm, a wall thickness of 18.4mm, and a gas internal pressure of 13.3MPa. Pressure sensors are installed at different positions of the natural gas pipeline axially and the busbar at 45°. The pressure sensors are used to measure the test process The gas pressure inside the steel pipe, the specific arrangement is as follows figure 1 and figure 2 As shown, record the pressure-time curve of the decompression wave during the blasting process at different positions, and then obtain the pressure-speed curve of the decompression wave of the steel pipe according to the pressure-time curve of the decompression wave during the blasting process at different positions, such as image 3 Shown.

[0041] 2) Obtain the pressure-crack growth rate curve of the pipe under different toughness conditions according to the steel pipe specifications and performance parameters.

[0042]

[0043]

[0044] Where P a Crack sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com