Large deformation resistant multiphase X100 high-strength steel plate for large diameter pipeline and manufacturing method for steel plate

A large-diameter pipe and anti-large deformation technology, which is applied in the field of large-diameter pipe anti-large deformation multi-phase X100 high-strength steel plate and its manufacturing field, can solve the problems of low elongation, no uniform elongation, poor safety, etc., and achieve grain Outstanding refinement and strength improvement, easy production and promotion, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

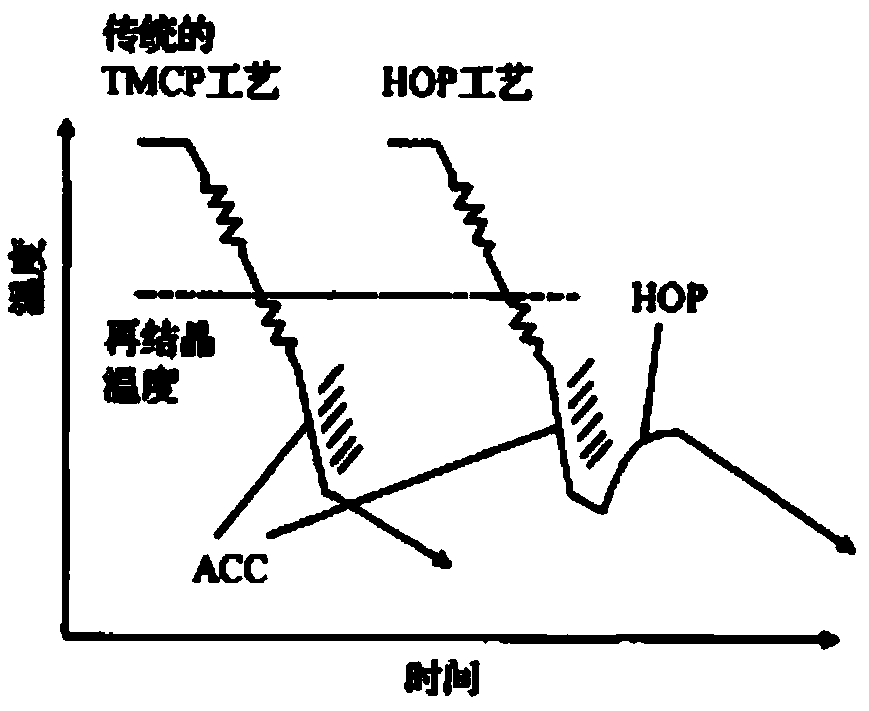

Method used

Image

Examples

Embodiment 1

[0035] The composition design of the anti-deformation X100 wide and thick steel plate involved in this implementation example is shown in Table 1:

[0036] Its preparation method concrete parameter is:

[0037] After the hot metal KR desulfurization treatment, the sulfur content of the molten iron is ≤0.004%, the converter smelting end point C is ≤0.04%, and the P is ≤0.007%. , Spheroidized inclusion morphology.

[0038] The steel smelting process of the present invention controls the addition sequence of alloy elements: deoxidation treatment is carried out after the converter, the amount of Al added during deoxidation is sufficient, and the first deoxidation is sufficient, and aluminum particles are added in the late stage of LF for deoxidation, and then Ti iron is added, and controlled according to the N content in the steel Add Ti content, Ti / N ratio is controlled at 2.6.

[0039] The slab continuous casting adopts dynamic soft reduction technology; in the slab reheating ...

Embodiment 2

[0044] The composition design of the anti-deformation X100 wide and thick steel plate involved in this implementation example is shown in Table 1:

[0045] Its preparation method concrete parameter is:

[0046] After the hot metal KR desulfurization treatment, the sulfur content of the molten iron is ≤0.004%, the converter smelting end point C is ≤0.04%, and the P is ≤0.007%. , Spheroidized inclusion morphology.

[0047] The steel smelting process of the present invention controls the addition sequence of alloy elements: deoxidation treatment is carried out after the converter, the amount of Al added during deoxidation is sufficient, and the first deoxidation is sufficient, and aluminum particles are added in the late stage of LF for deoxidation, and then Ti iron is added, and controlled according to the N content in the steel Add Ti content, Ti / N ratio is controlled at 2.8.

[0048] The slab continuous casting adopts dynamic soft reduction technology; in the slab reheating ...

Embodiment 3

[0053] The composition design of the anti-deformation X100 wide and thick steel plate involved in this implementation example is shown in Table 1:

[0054] Its preparation method concrete parameter is:

[0055] After the hot metal KR desulfurization treatment, the sulfur content of the molten iron is ≤0.004%, the converter smelting end point C is ≤0.04%, and the P is ≤0.007%. , Spheroidized inclusion morphology.

[0056] The steel smelting process of the present invention controls the addition sequence of alloy elements: deoxidation treatment is carried out after the converter, the amount of Al added during deoxidation is sufficient, and the first deoxidation is sufficient, and aluminum particles are added in the late stage of LF for deoxidation, and then Ti iron is added, and controlled according to the N content in the steel The Ti content is added, and the Ti / N ratio is controlled at 2.0.

[0057] The slab continuous casting adopts dynamic soft reduction technology; in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com