Measuring scale for drop weight tear tests and method for measuring fracture surfaces of drop weight tear test samples

A technology of drop weight tearing test and measurement method, which is applied in the direction of measuring device, mechanical measuring device, ruler for direct reading, etc., can solve the problems of inability to guarantee the quality of judgment, affect work efficiency, and high judgment cost, and achieve good utilization The effect of value, ease of operation, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

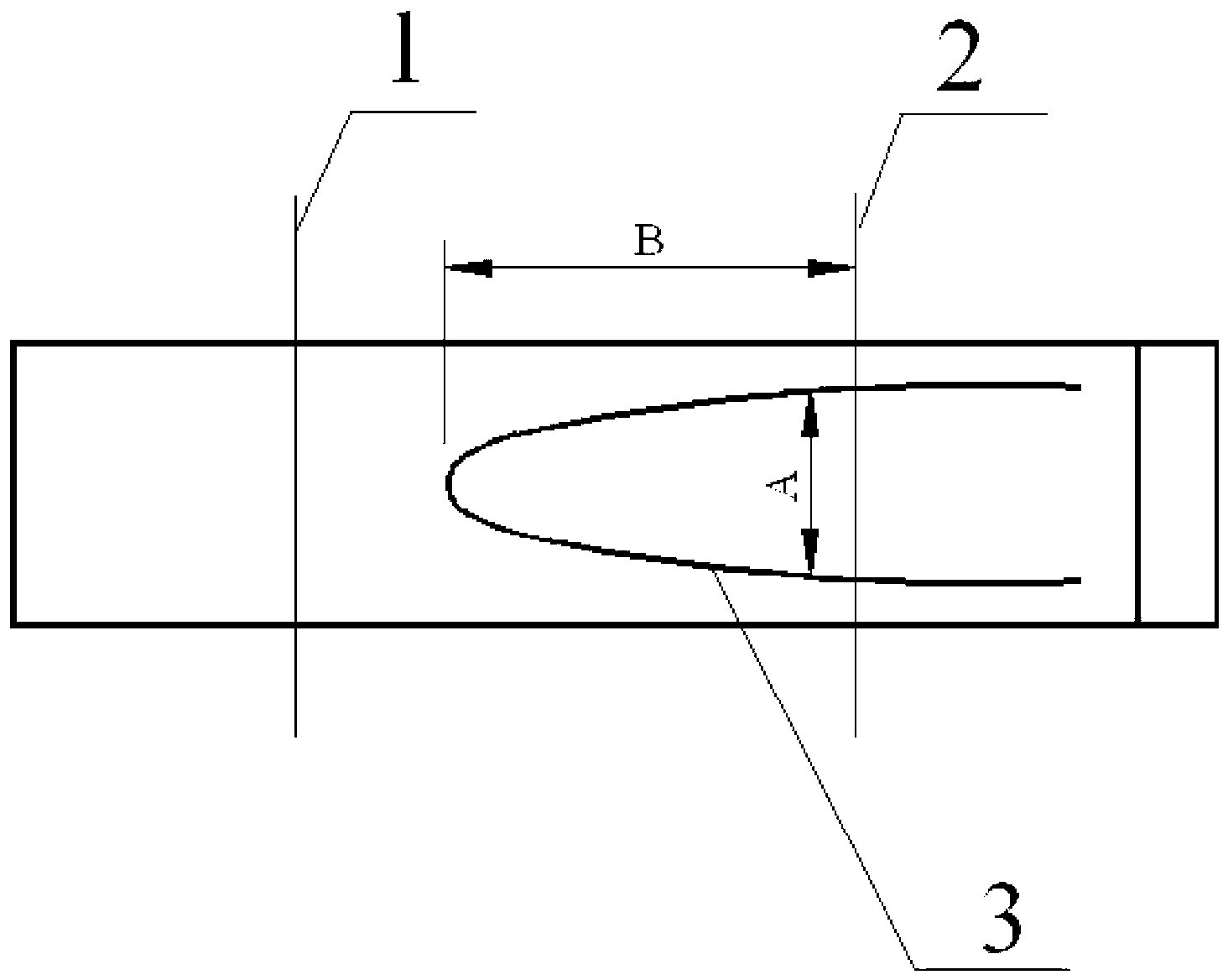

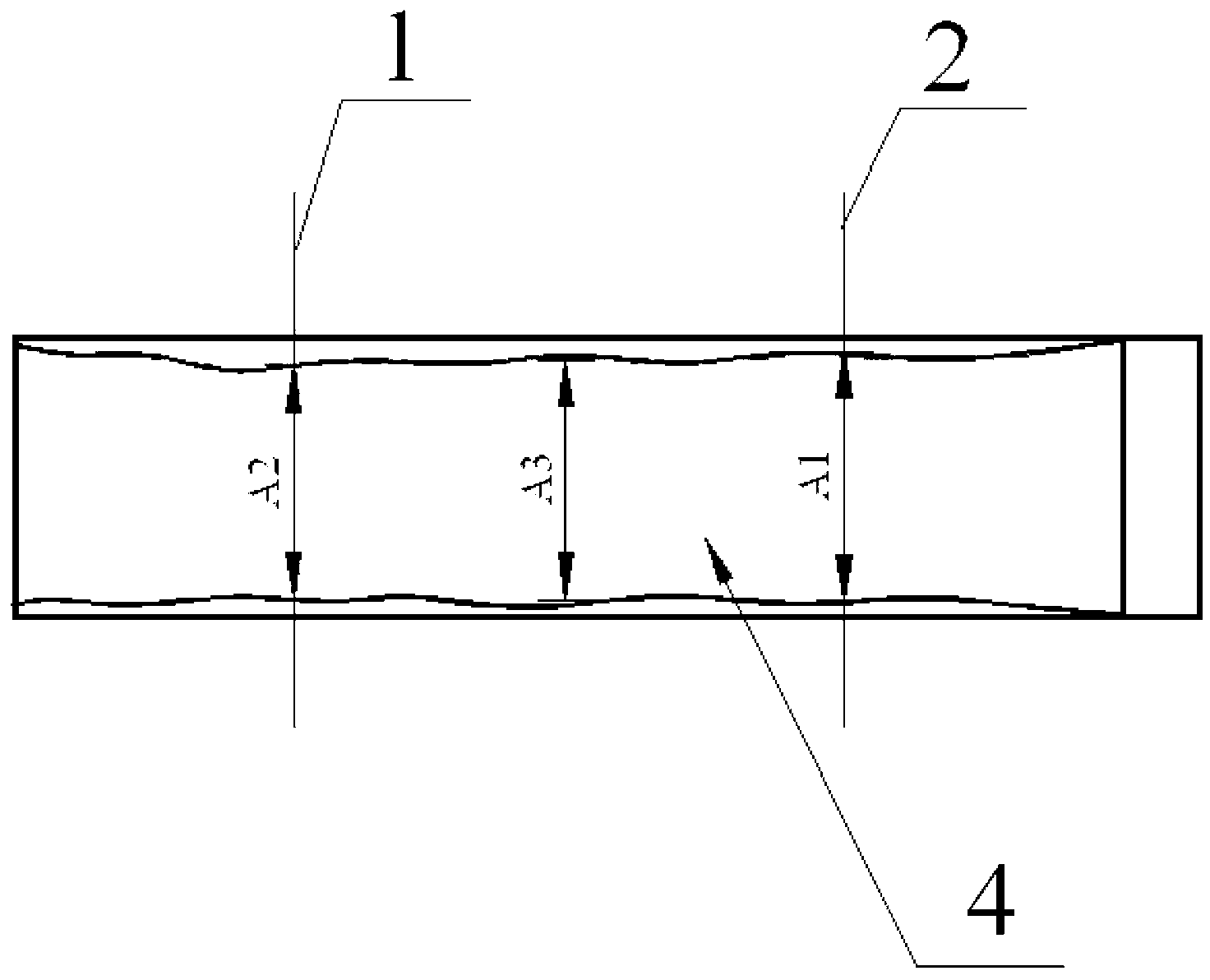

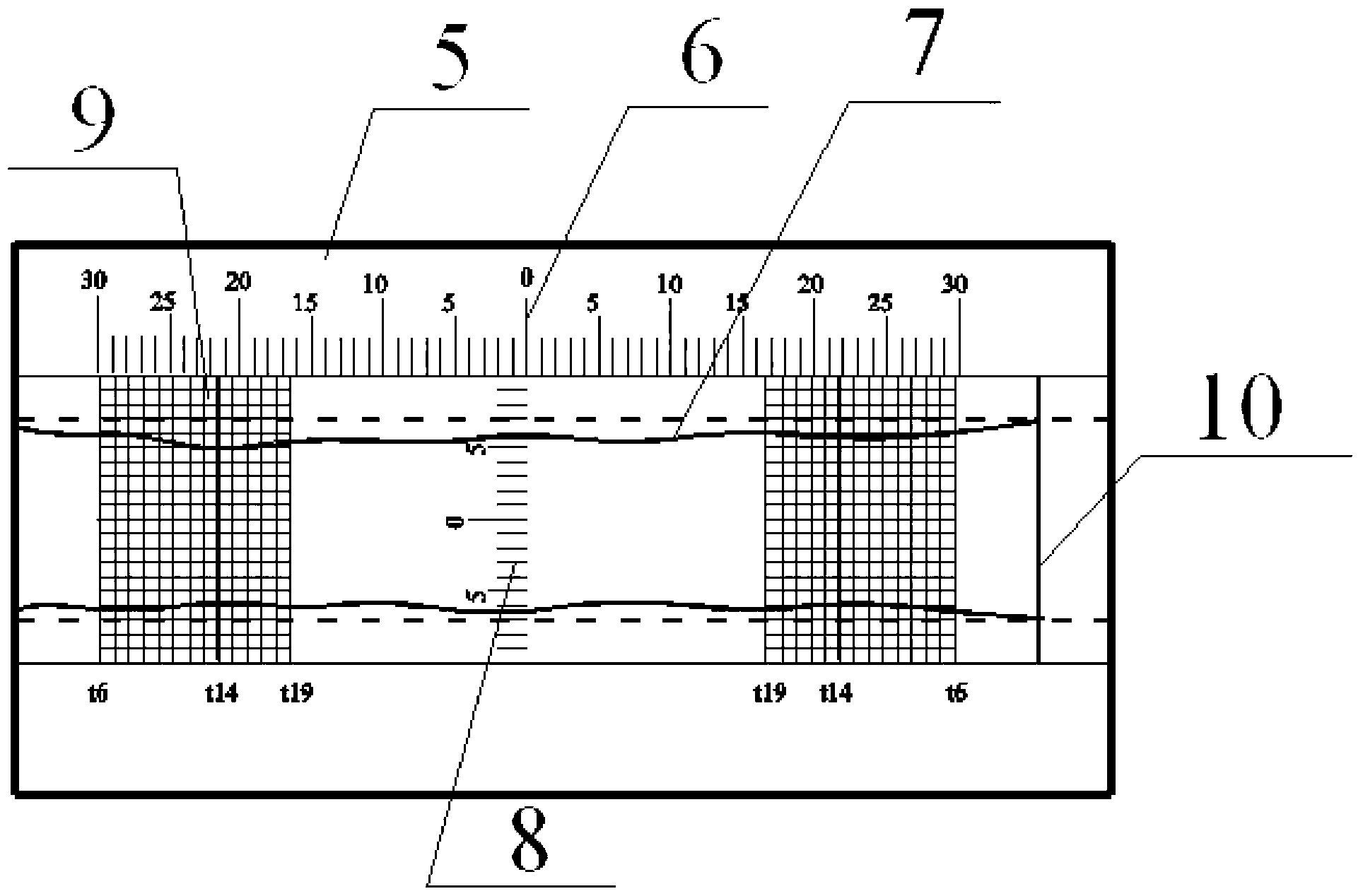

[0045] refer to Figure 1 to Figure 3 , The embodiment of the present invention provides a measuring ruler for a drop weight tear test, comprising a measuring ruler body 5, the measuring area of the measuring ruler body 5 has a length of 76.2mm and a width of 40mm. The thickness of the measuring ruler body 5 is 1 mm, the material is a transparent material, and the size of the length 76.2 mm is exactly the same as the fracture length of the sample 7 . The upper part of the measuring ruler body 5 is marked with a horizontal scale line 6, the length of the horizontal scale line is 60mm, and the distance between the horizontal scale lines is 1mm, and the horizontal scale line 6 is used for measuring figure 1 Moderately ductile fracture zone 3 length B. Measuring scale body 5 middle part is drawn with vertical scale line 8, and horizontal scale line 6 is perpendicular to vertical scale line 8, and the length of vertical scale line 8 is 20mm, and the spacing between vertical scal...

Embodiment 2

[0049] refer to figure 1 , figure 2 with Figure 4 , In this embodiment, the sample 7 with a thickness of 16 mm is taken as an example, and its fracture type belongs to ductile fracture. The specific position of the line t can be determined as t16 firstly by using the grids 9 on the left and right sides, and then the length of the ductile fracture zone 3 can be measured by the horizontal scale 6 . Finally, use the vertical scale line 8 to measure the width of the ductile fracture zone 3 at the t-line 2 on the notch side, and then calculate the shear section ratio SA according to the corresponding formula.

[0050] The measuring ruler is reasonable in design, easy to operate and low in production cost. The t-line 1 on the hammer side and the t-line 2 on the notch side can be quickly positioned without drawing auxiliary lines. More importantly, the measuring ruler does not need other measuring tools, and the measuring ruler can directly measure various characteristic dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com