Method and device for determining sample toughness in pipeline steel drop weight tear test

A technology of falling weight tearing and pipeline steel, which is applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problem of shear area ratio deviation and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

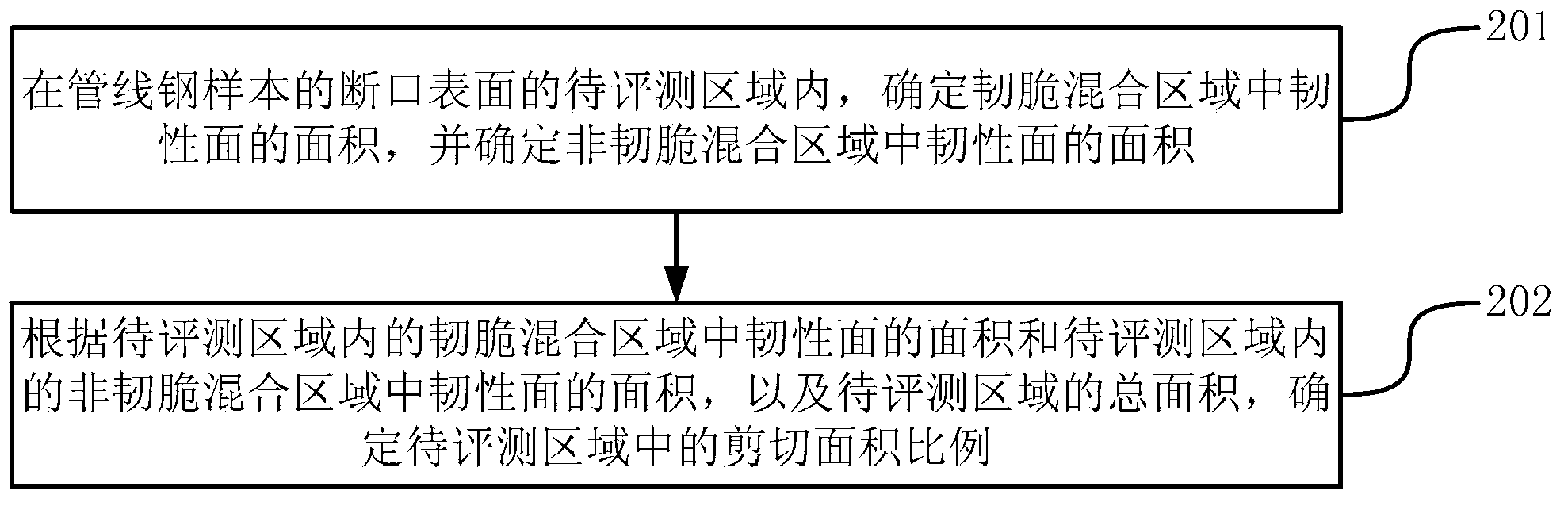

[0044] The embodiment of the present invention provides a method for determining the toughness of a sample in a pipeline steel drop weight tearing test, such as figure 2 As shown, the processing flow of the method may include the following steps:

[0045] Step 201, in the region to be evaluated on the fracture surface of the pipeline steel sample, determine the area of the ductile surface in the ductile-brittle mixed region, and determine the area of the ductile surface in the non-ductile-brittle mixed region. Wherein, the ductile-brittle mixed region is a triangular-like region in which the tough surface and the brittle surface are distributed in stripes at intervals.

[0046] Step 202, according to the area of the tough surface in the ductile-brittle mixed region in the region to be evaluated, the area of the ductile surface in the non-ductile and brittle mixed region in the region to be evaluated, and the total area of the region to be evaluated, determine the sh...

Embodiment 2

[0049] The embodiment of the present invention provides a method for determining the toughness of a sample in a pipeline steel drop weight tearing test, which will be described in conjunction with specific implementation methods below figure 2 The processing flow shown will be described in detail, and the specific content may be as follows.

[0050] Step 201, in the region to be evaluated on the fracture surface of the pipeline steel sample, determine the area of the ductile surface in the ductile-brittle mixed region, and determine the area of the ductile surface in the non-ductile-brittle mixed region.

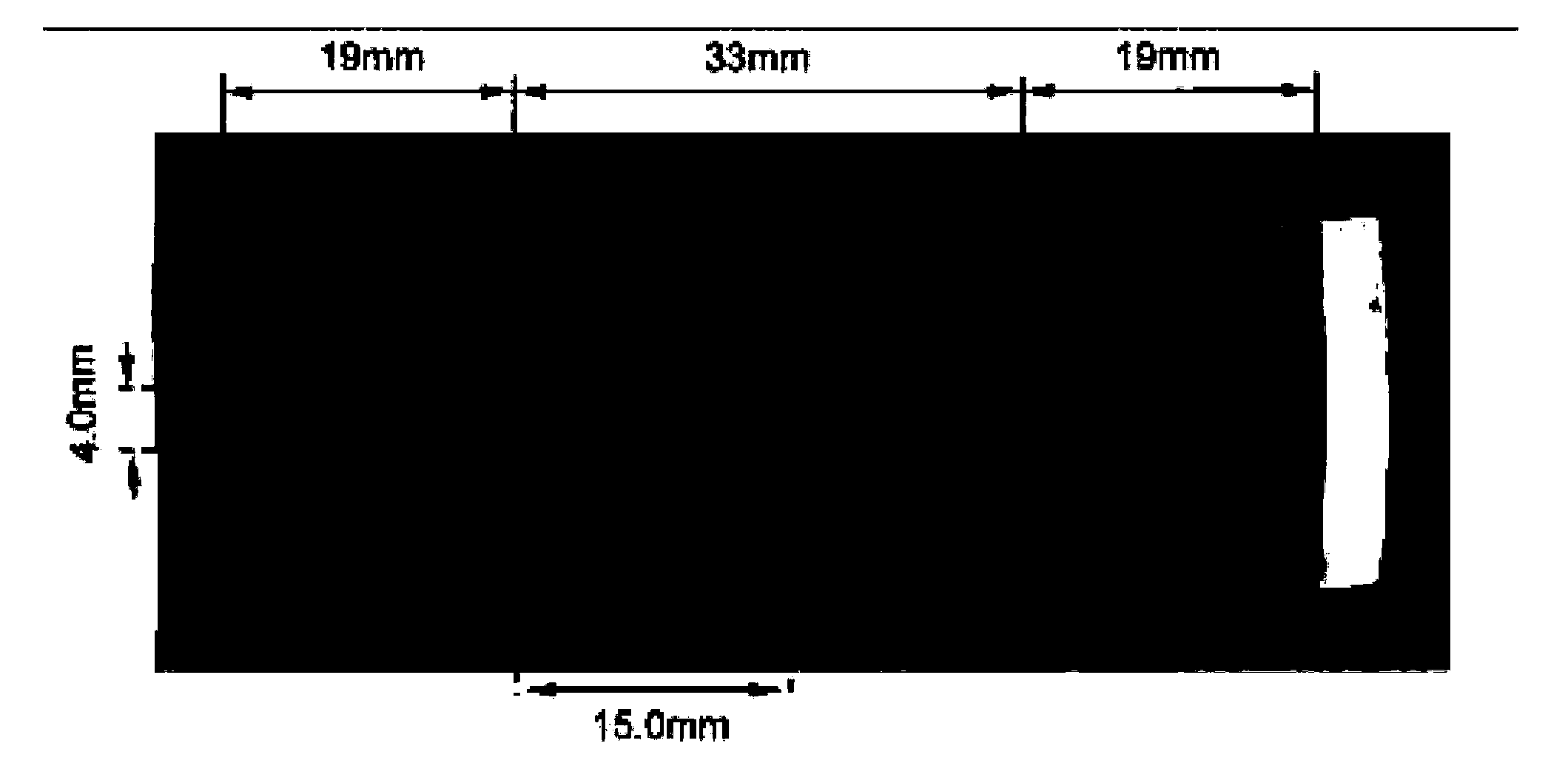

[0051] Among them, X80 (pipeline steel type) pipeline steel can be used for 0°C pipeline steel drop weight tearing test. The area to be evaluated can be as figure 1 The region where the middle width of the fracture surface of the pipeline steel sample is taken is 33mm. The ductile-brittle mixed region in the area to be evaluated is figure 1 Areas 1, 2 in . The non-d...

Embodiment 3

[0067] Based on the same technical idea, the embodiment of the present invention also provides a device for determining the toughness of a sample in a pipeline steel drop weight tear test, such as Figure 6 As shown, the device includes:

[0068] The first determination module 610 is used to determine the area of the ductile surface in the ductile-brittle mixed region and determine the area of the ductile surface in the non-ductile-brittle mixed region in the area to be evaluated on the fracture surface of the pipeline steel sample, wherein the ductile The brittle mixed area is a triangular area in which the ductile surface and the brittle surface are distributed in stripes at intervals;

[0069] The second determining module 620 is used for determining the area of the tough surface in the ductile-brittle mixed region in the region to be evaluated and the area of the ductile surface in the non-ductile and brittle mixed region in the region to be evaluated, and the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com