Process for preparing back point-contact crystalline-silicon solar cells

A point-contact and solar cell technology on the back, applied in the field of solar cells, can solve problems such as difficult mass production, poor opening effect of the passivation layer on the back, difficult ohmic contact, etc., to achieve enhanced adhesion and good optical back reflection Performance, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

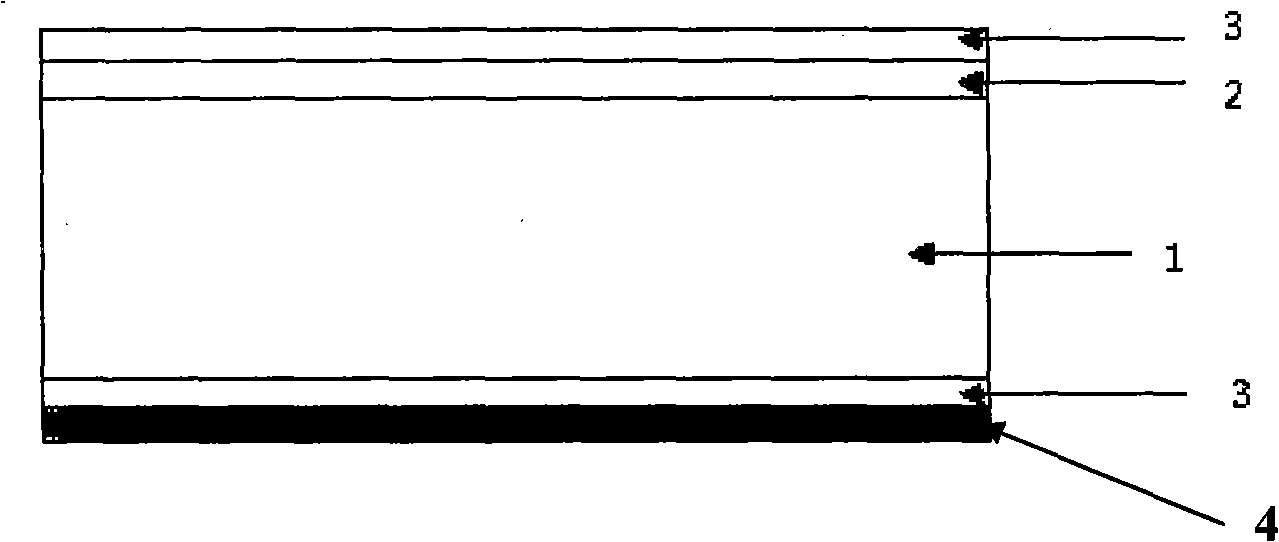

[0045] The preparation process of the rear point contact crystalline silicon solar cell provided in this embodiment, as attached figure 2 , 3 , 4, 5, 7 and 8, plate silicon dioxide 3 and silicon nitride 4 composite passivation film on the back of silicon chip 1, and adopt silicon paste screen printing on the composite passivation film with silicon paste with point contact pattern slurry layer 5, then use hydrofluoric acid solution to etch away the area not covered by the silicon paste layer in the composite passivation film, then screen print the aluminum paste layer 7 on the back of the silicon chip, and make the aluminum paste layer and the silicon paste layer by sintering A silicon-aluminum alloy layer 8 is formed on the contact surface, and the silicon-aluminum alloy layer 8 further enhances the adhesion of the aluminum layer. Because the thickness of the aluminum paste layer is relatively large, it can effectively prevent the aluminum paste from being applied to the SiO ...

Embodiment 2

[0059] as attached Figure 1-9 Shown: the preparation process of the rear point contact crystalline silicon solar cell provided in this embodiment includes the following steps:

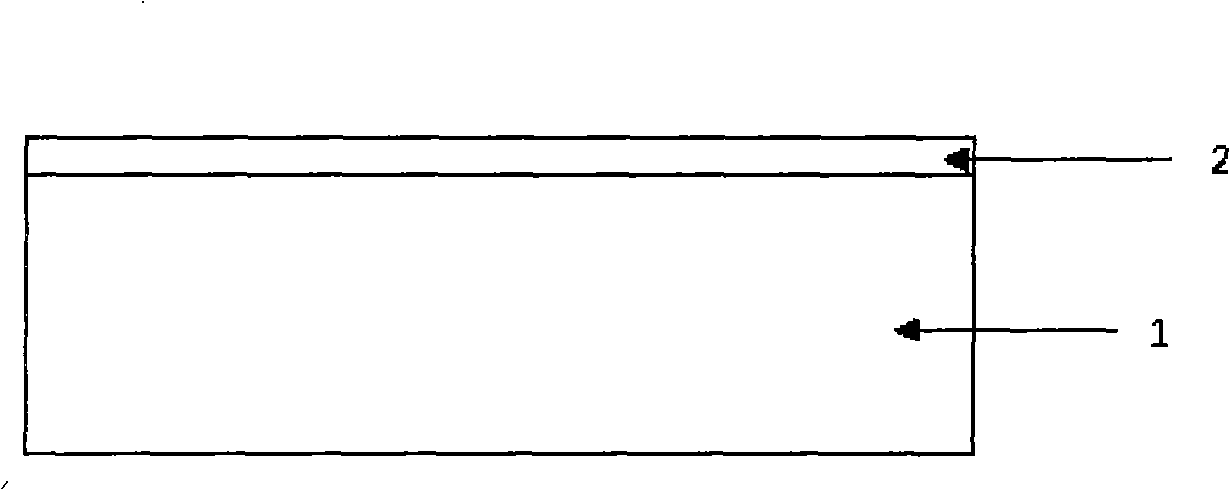

[0060] (1) forming an N-type layer 2 through diffusion on the front surface of the silicon wafer 1;

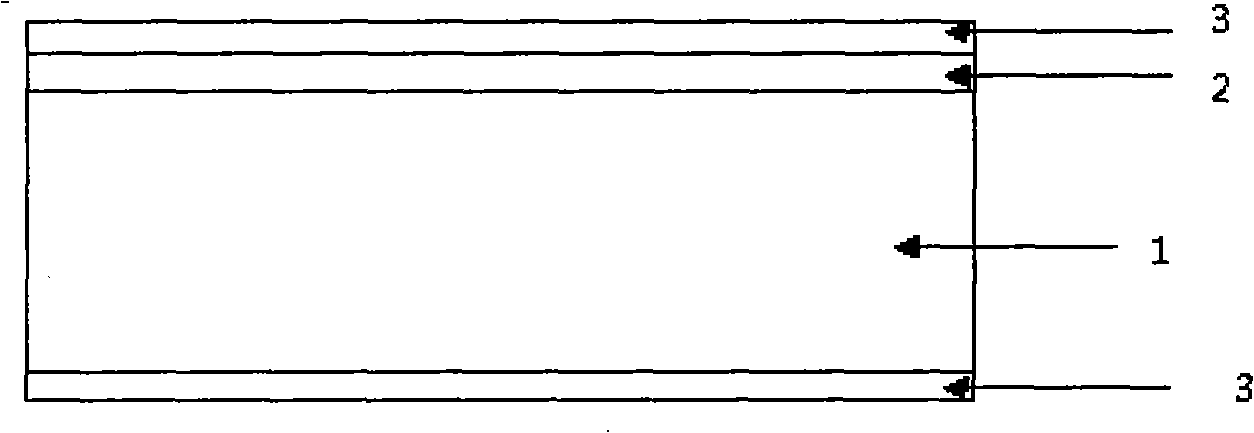

[0061] (2) forming a silicon dioxide layer 3 by thermal oxidation on both sides of the silicon wafer;

[0062] (3) coat one layer of silicon nitride 4 on the back side of the silicon wafer to form a composite passivation film of silicon dioxide and silicon nitride;

[0063] (4) On the composite passivation film, a silicon paste layer 5 with a point contact pattern is screen-printed with a silicon paste;

[0064] (5) using a chemical etching solution to etch away the area not covered by the silicon paste layer in the composite passivation film to form a point electrode contact hole, and simultaneously corrode the silicon dioxide layer on the front surface of the silicon wafer;

[0065] (6) coat the ...

Embodiment 3

[0080] Reference attached Figure 1-9 As shown, the preparation process of the rear point contact crystalline silicon solar cell provided in this embodiment includes the following steps:

[0081] (1) N-type layer 2 is formed by diffusion on both surfaces of silicon wafer 1;

[0082] (2) Remove the N-type layer on the back with acid or alkali, by first covering the N-type layer on the front, and removing the mask after removal;

[0083] (3) form a silicon dioxide layer 3 by thermal oxidation on both sides of the silicon wafer;

[0084] (4) coat a layer of silicon nitride 4 on the back side of the silicon wafer to form a composite passivation film of silicon dioxide and silicon nitride;

[0085] (5) On the composite passivation film, a silicon paste layer 5 with a point contact pattern is screen-printed with a silicon paste;

[0086] (6) using a chemical etching solution to etch away the area not covered by the silicon paste layer in the composite passivation film to form a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com