Aluminum alloy clad material for molding

A technology of aluminum alloy cladding and forming processing, applied in the direction of metal layer products, metal processing equipment, welding/cutting medium/material, etc. Abnormal quality and other problems, to achieve the effect of excellent sinter hardening and corrosion resistance, high mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Hereinafter, examples of the present invention will be described together with comparative examples. In addition, the following examples are used to illustrate the effects of the present invention, and the steps and conditions described in the examples do not limit the technical scope of the present invention.

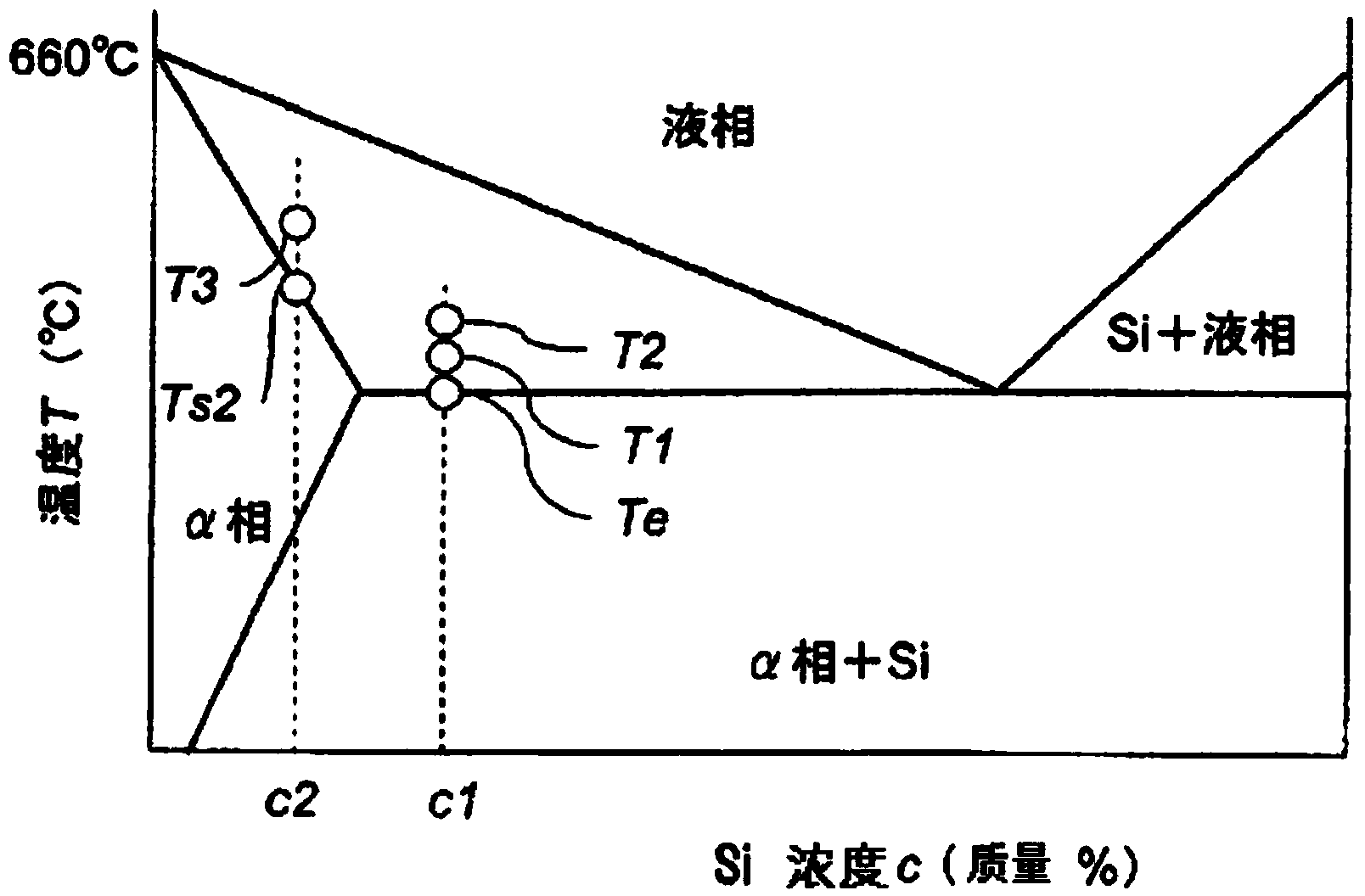

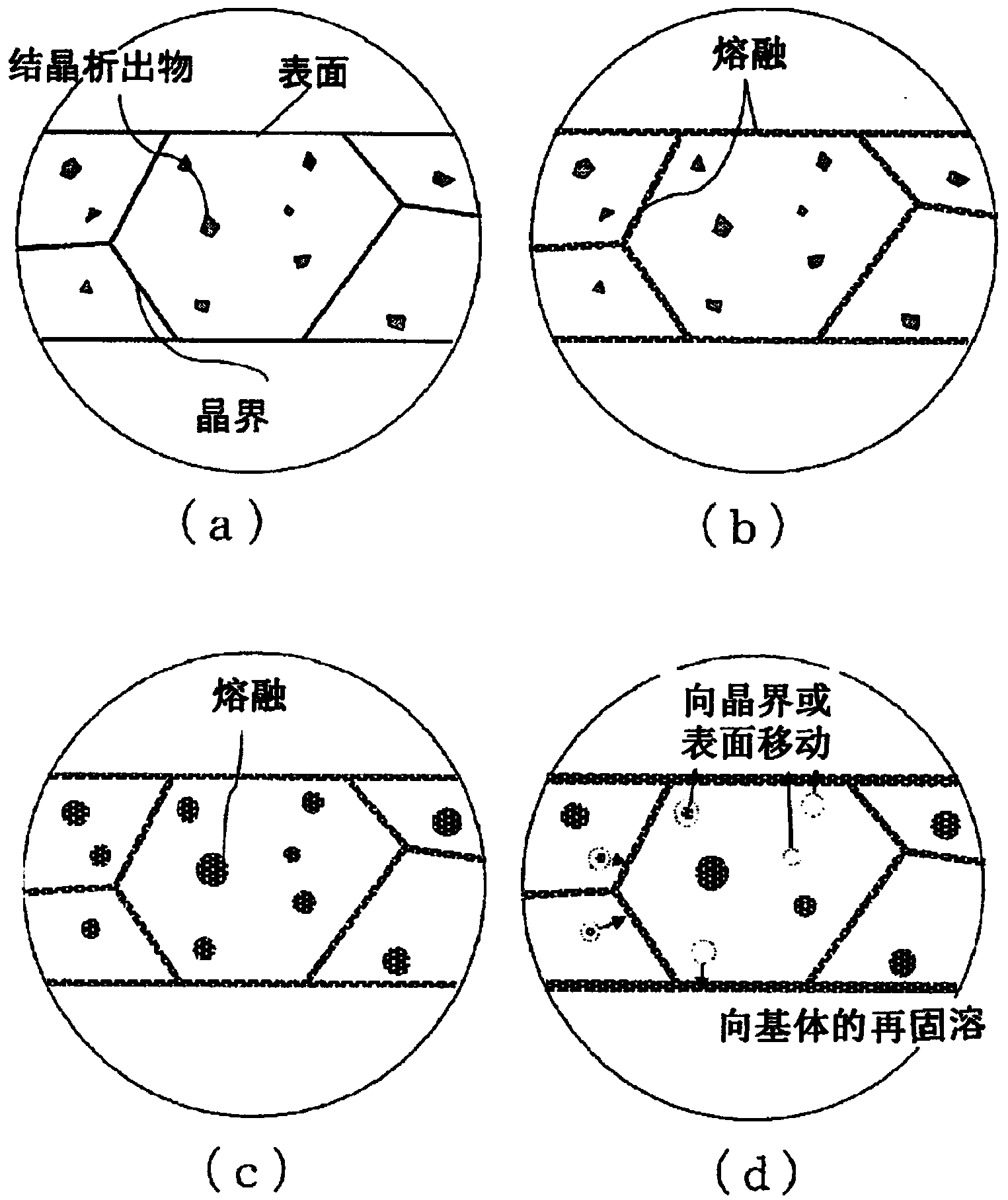

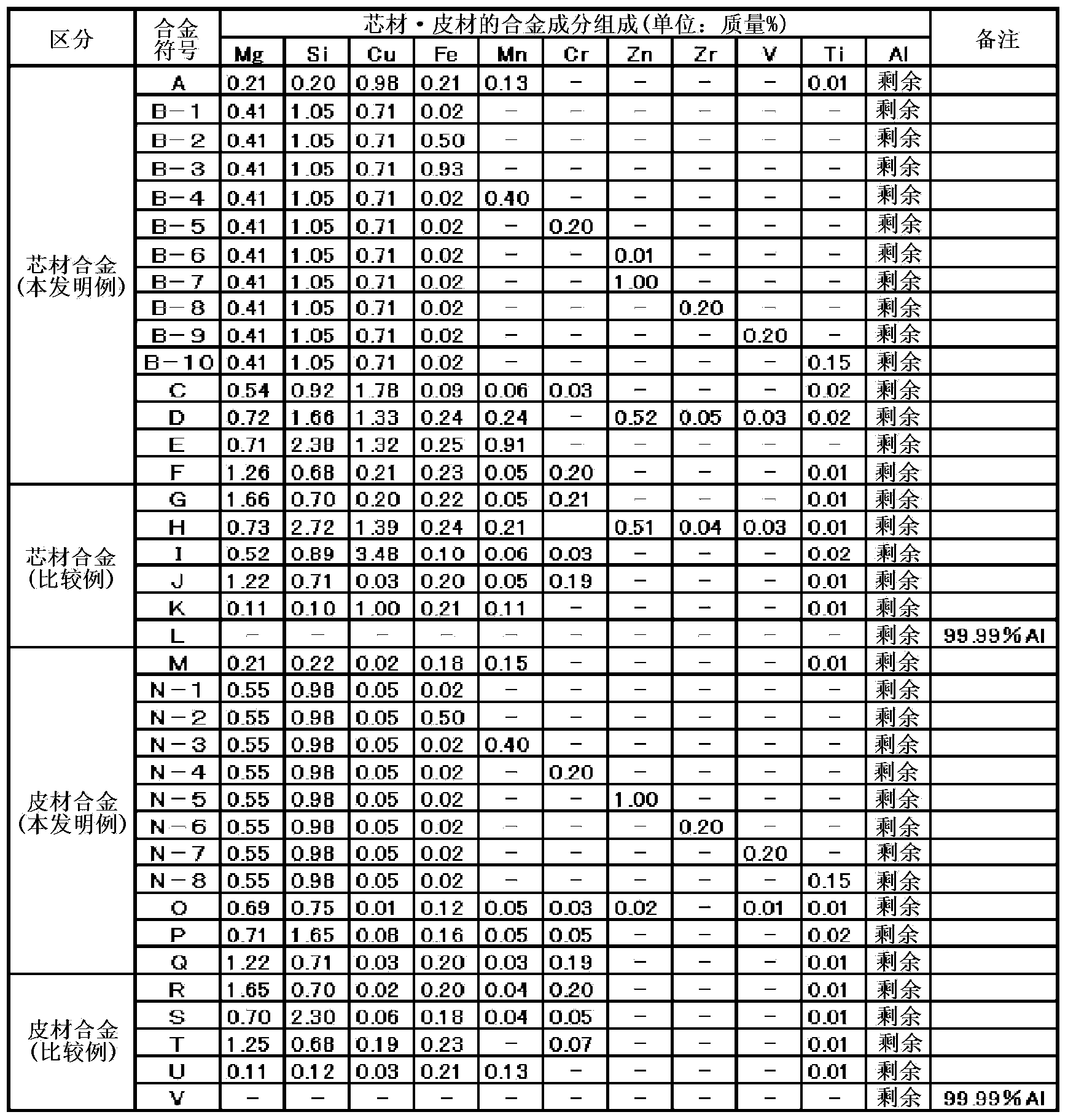

[0098] First, the alloy symbols A~F and M~Q used as the core material or skin material raw materials of the composition shown in Table 1 were smelted according to conventional methods, and the alloy symbols G~L and R~V used as comparative examples, and The alloy symbols 3-5, 7-29, 31-57 used as the raw material of the intercalation material composition shown in Table 2 and 3, and the alloy symbols 1, 2, 6, 30 as the comparative example of the intercalation material, and passed The DC casting method casts them as slabs. In addition, in Table 1, alloys having component compositions falling outside the range of the present invention are indicated as "comparative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com