Method for manufacturing hydrodynamic bearing and rotating shaft

A technology of a dynamic pressure bearing and a manufacturing method, which is applied to sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as difficulty in ensuring dimensional accuracy, narrow bearing hollow parts, and difficulty in improving product mass production and stability. , to achieve the effect of improving mass productivity and dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

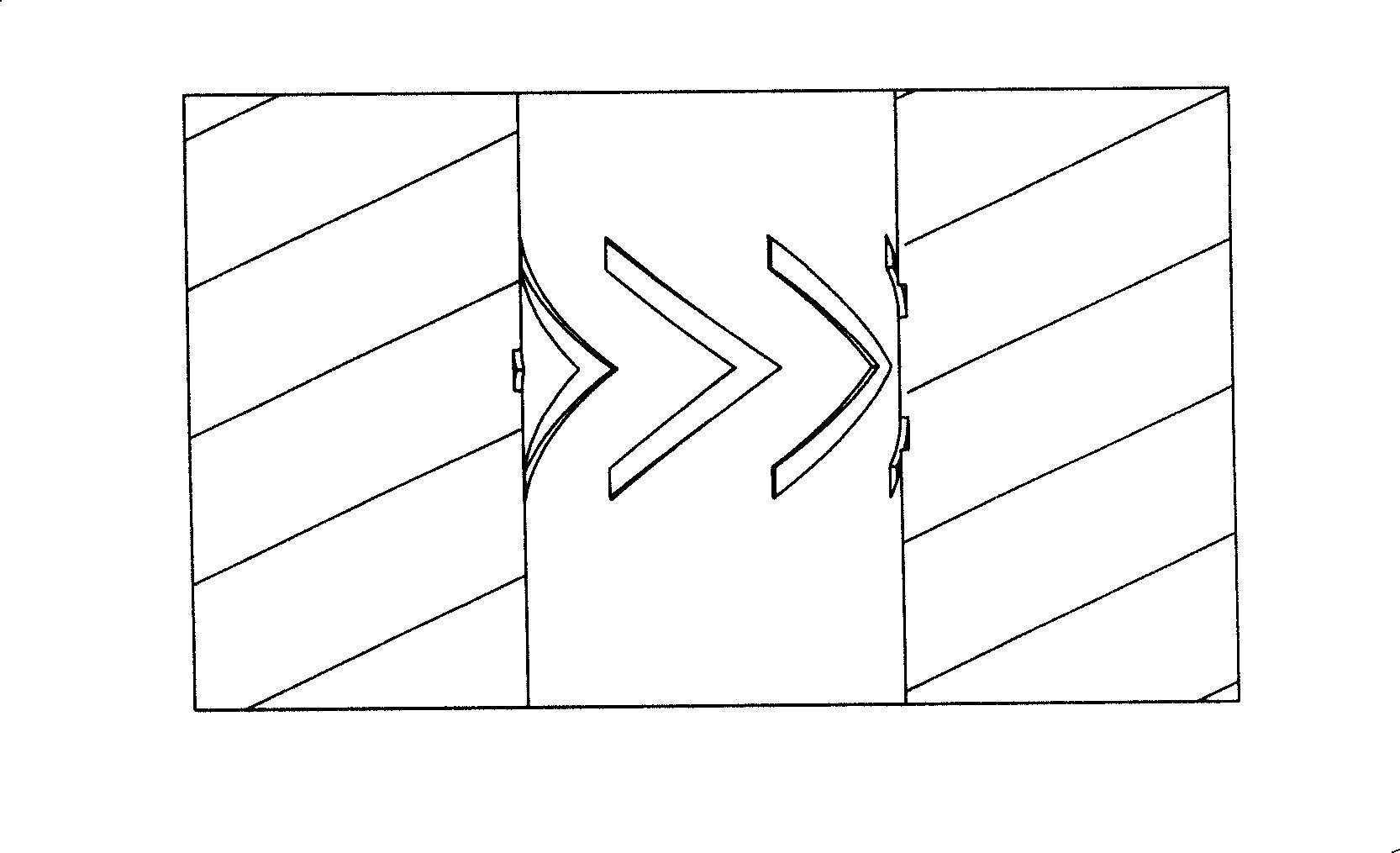

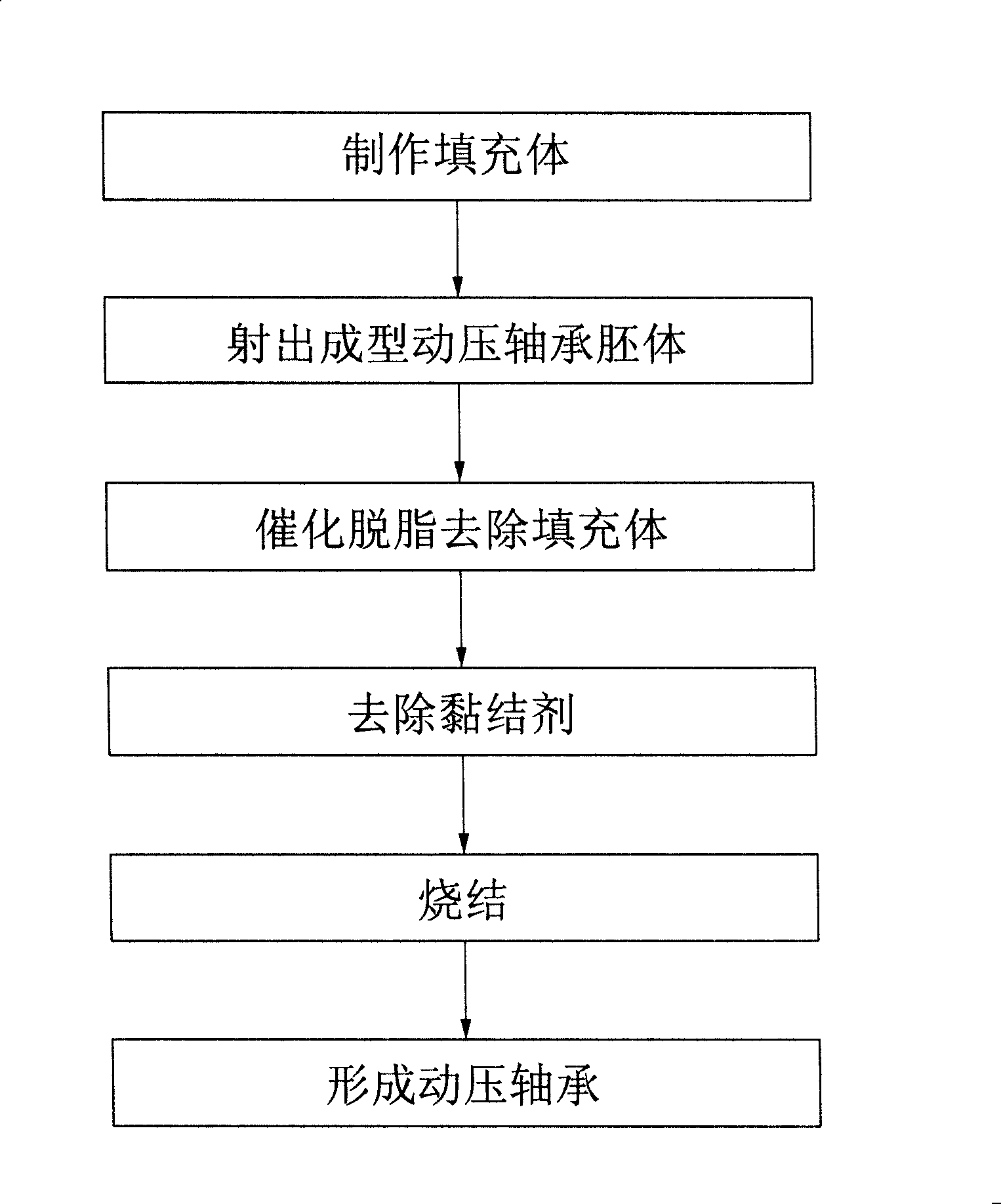

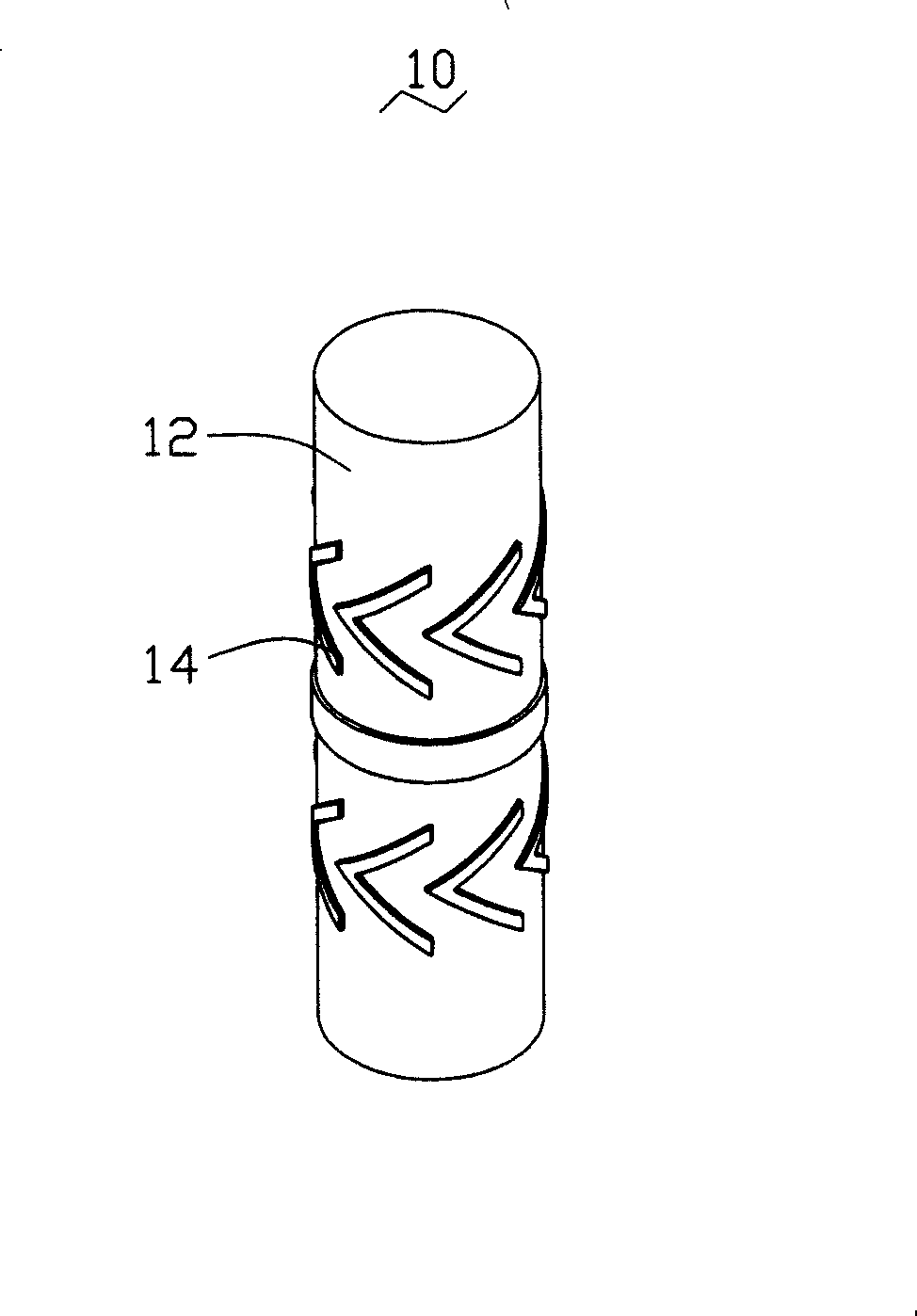

[0015] see Figure 2 to Figure 5 , the surface of the inner hole of the dynamic pressure bearing 30 according to an embodiment of the present invention is distributed with a number of "herringbone" shaped dynamic pressure grooves 34, and these dynamic pressure grooves 34 are used to generate a dynamic pressure effect. The manufacturing method of the dynamic pressure bearing 30 includes the following steps: firstly, a filling body 10 is provided, and the surface of the filling body 10 is provided with a plurality of protrusions 14; secondly, the filling body 10 is placed in a hollow bearing mold (not shown in the figure) ), and fill the metal powder or ceramic powder material into the hollow cavity of the bearing mold by injection molding to form the dynamic pressure bearing blank body 20; again, the filling body 10 is degreased by catalytic Removed from the dynamic pressure bearing blank 20, so that the inner wall surface of the dynamic pressure bearing blank 20 has just forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com