Preparation method of local binderless reinforce panel

A local adhesive-free and reinforcing sheet technology, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as low production quality and achieve the effect of improving mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0022] Embodiments of the present invention include: a method for preparing a partially glue-free reinforcing sheet, the steps of the preparation method comprising:

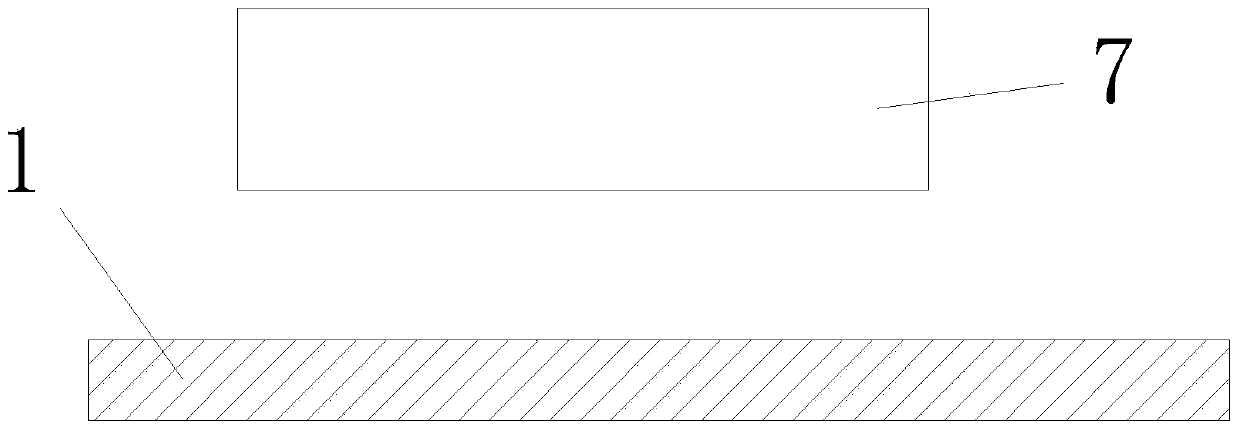

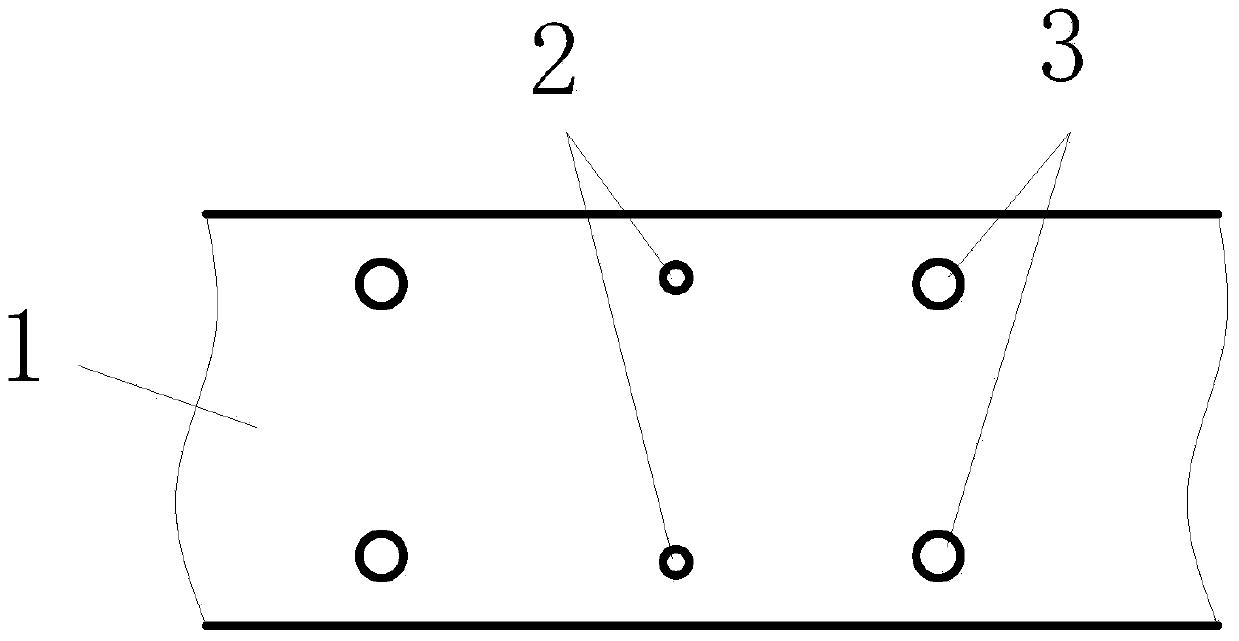

[0023] First, use the substrate punching die 7 to punch the substrate 1 out of the product hole 2 and the substrate positioning hole 3;

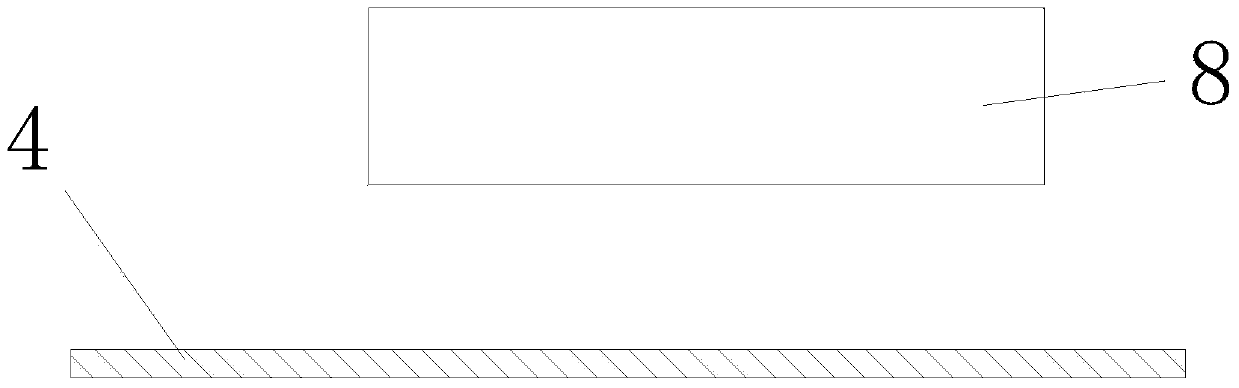

[0024] Second, use the rubber material punching die 8 to punch the rubber material 4 out of the relief area 5 and the rubber material positioning hole 6;

[0025] Thirdly, guide the die-cut base material 1 and adhesive material 4 through the glue-covered guide rod 10;

[0026] Fourth, press the aligned base material 1 and adhesive material 4 through the positioning an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com