Preparation method of fructose sodium diphosphate powder injection

A technology of sodium fructose diphosphate and powder injection, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc. It can solve the problems of high equipment requirements, poor absorbability, poor stability, etc., and achieve improved yield and quality Stability, economical production process, and the effect of reducing allergenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

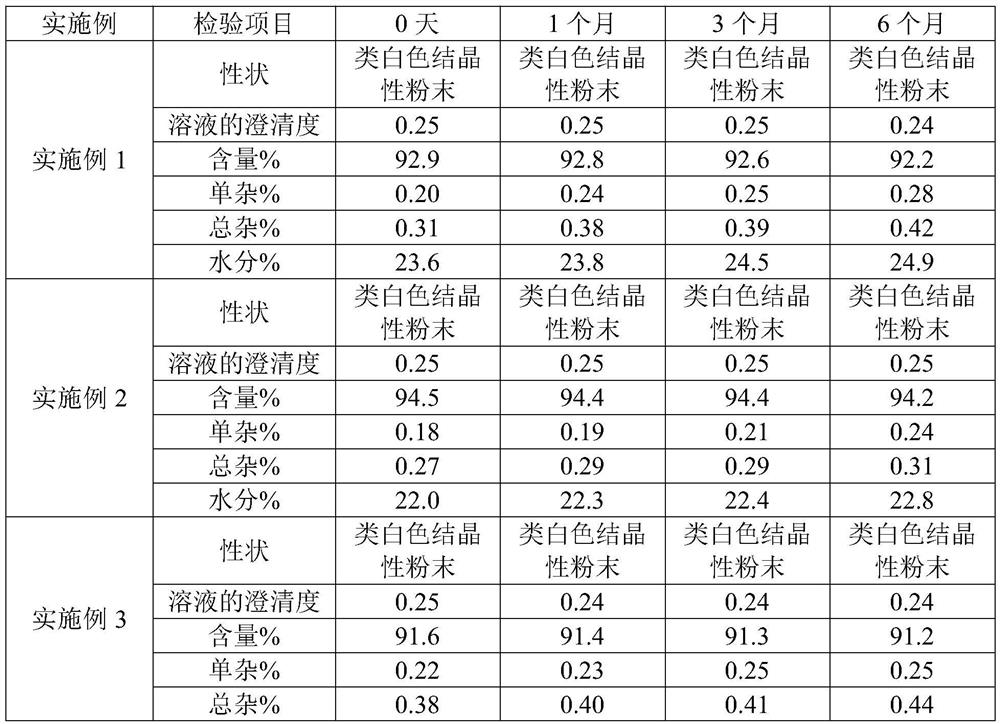

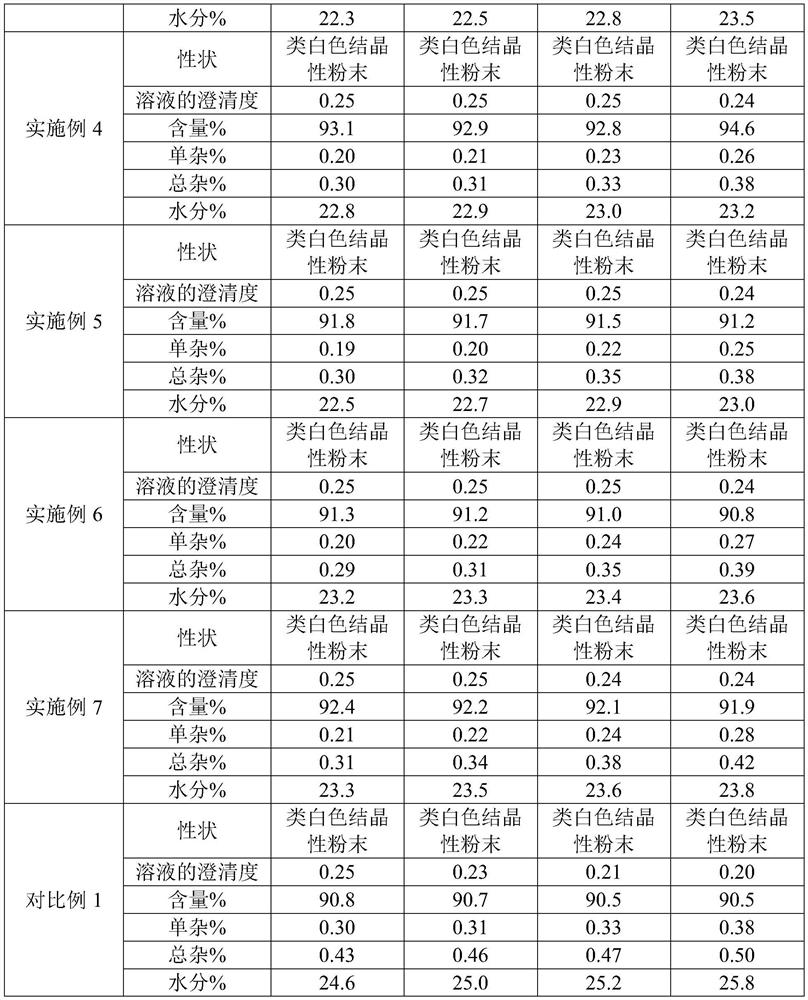

Examples

Embodiment 1

[0030]1) Put 5kg of crude fructose diphosphate and 25L of water for injection in a clean container for stirring and dissolving, and then add 100g of activated carbon to the container for decolorization and stirring. The stirring time is 25 minutes;

[0031]2) Decarburize and filter the solution to obtain a filtrate, and rinse the filtered activated carbon with 5L of water for injection, combine the rinsed solution with the filtrate, and perform sterile filtration to obtain a crude solution of sterile sodium fructose diphosphate;

[0032]3) Control the temperature of the crystallization tank to 25°C, add 18L of sterilized 95% ethanol to it, and then mix the crude sodium fructose diphosphate solution obtained in step 2) with 24L of sterilized Water ethanol is added to the above 95% ethanol, the stirring speed is 90r / min, the dripping time of the absolute ethanol is 2h, after the addition, it is allowed to stand for 1 hour for crystal growth;

[0033]4) Add 60L of absolute ethanol to the crysta...

Embodiment 2

[0036]1) Put 100kg of crude fructose diphosphate sodium and 250L of water for injection in a clean container for stirring and dissolving, and then add 2kg of activated carbon to the container for decolorization and stirring. The stirring time is 30 minutes;

[0037]2) Decarburize and filter the solution to obtain a filtrate, and rinse the filtered activated carbon with 50L of water for injection, combine the rinsed solution with the filtrate, and perform sterile filtration to obtain a crude solution of sterile sodium fructose diphosphate;

[0038]3) Control the temperature of the crystallization tank to 20°C, add 60L of sterilized 95% ethanol to it, and then mix the crude sodium fructose diphosphate solution obtained in step 2) with 420L of sterilized Water ethanol is added to the above 95% ethanol, the stirring speed is 65r / min, the dripping time of absolute ethanol is 2.5h, and after the addition, it is allowed to stand for 2 hours for crystal growth;

[0039]4) Add 600L of absolute ethano...

Embodiment 3

[0042]1) Put 30kg of crude fructose diphosphate and 50L of water for injection in a clean container for stirring and dissolving, and then add 600g of activated carbon to the container for decolorization and stirring. The stirring time is 35 minutes;

[0043]2) Decarburize and filter the solution to obtain a filtrate, and rinse the filtered activated carbon with 10L of water for injection, combine the rinsed solution with the filtrate, and perform sterile filtration to obtain a crude solution of sterile sodium fructose diphosphate;

[0044]3) Control the temperature of the crystallization tank to 16°C, add 24L of sterilized 95% ethanol to it, and then mix the crude sodium fructose diphosphate solution obtained in step 2) with 144L of sterilized Water and ethanol were simultaneously added to the above 95% ethanol, the stirring speed was 50r / min, and the dripping time of the absolute ethanol was 1.5h, after the addition, it was allowed to stand for 1.5 hours for crystal growth;

[0045]4) Add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com