A board for furniture

A technology for boards and furniture, applied in furniture parts, home appliances, applications, etc., can solve the problems that wooden materials are susceptible to moisture, affect the service life of sofas, reduce efficiency, etc., reduce work intensity and production costs, and quickly and easily assemble furniture. , the effect of reduced production procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

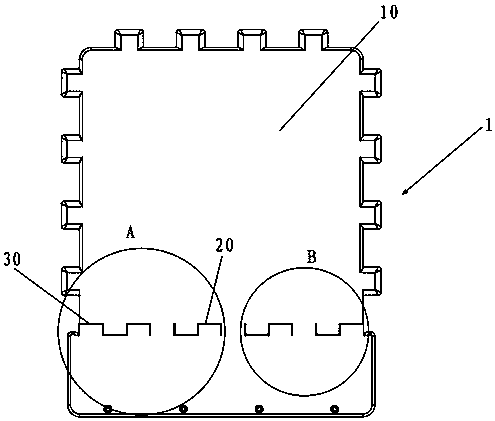

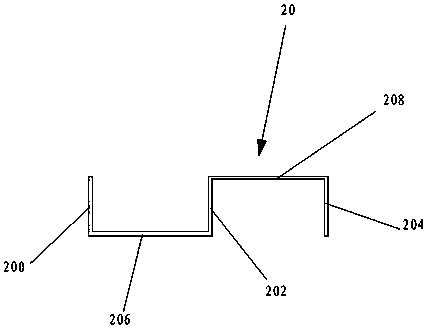

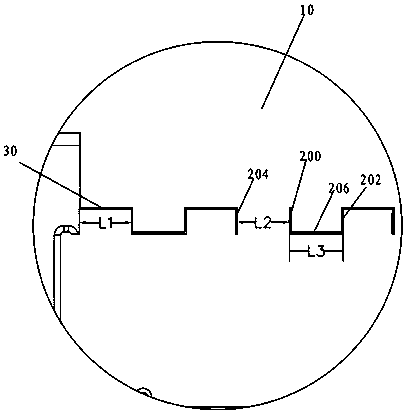

[0034] like figure 1 , figure 2 As shown, the slit 20 includes a first slit 200, a second slit 202, and a third slit 204 spaced side by side, and one end of the first slit 200 and one end of the second slit 202 are provided with a connecting first slit, The fourth slot 206 of the second slot, the other end of the second slot 202 and the other end of the third slot 204 are provided with a fifth slot 208 communicating with the second slot and the third slot.

[0035] refer to figure 2 , the first slit 200, the second slit 202 and the third slit 204 are parallel to each other, the fourth slit 206 is perpendicular to the first slit 200 and the second slit 202, and the fifth slit 208 is perpendicular to the second slit 202 , The third slits 204 are perpendicular to each other; the above-mentioned vertical relationship is only a preferred implementation mode between them, and they may not be perpendicular to each other, forming an obtuse angle or an acute angle, and the drawings...

Embodiment approach

[0042] One is: the openings of two adjacent "匚"-shaped slits 21 have the same opening orientation, please refer to the accompanying drawings for details Figure 8 .

[0043]The other is: the openings of two adjacent "匚"-shaped slits 21 face opposite directions, please refer to the accompanying drawings for details Figure 9 .

[0044] In a preferred implementation of this example: the two sides of the above-mentioned "匚"-shaped slit are parallel and have the same length, please refer to the accompanying drawings for details Figure 8 , Figure 9 ; When it is not necessary to be equal, the drawing of the accompanying drawings is not performed here for this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com