Combined extraction preparation method of complex polypeptide

A technology of combined extraction and extract, applied in the preparation methods of peptides, chemical instruments and methods, peptides, etc., can solve the problems of affecting the health of operators, loss of efficacy and application value of peptides, and increase of extraction costs, and achieve compatibility. and good solubility, effective extraction process, and the effect of reducing the cost of extraction and preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

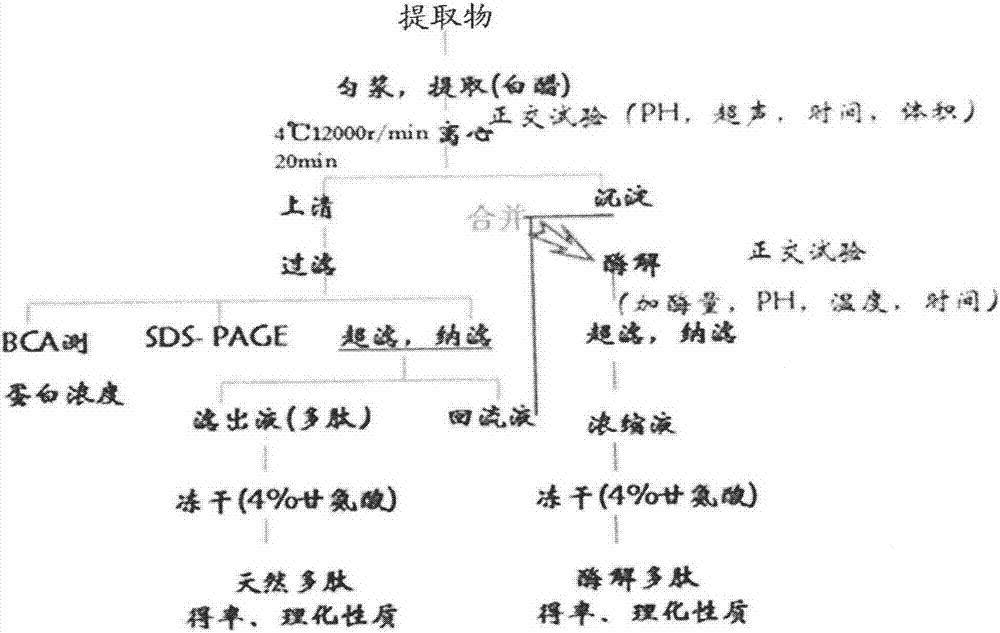

[0058] Example 1: Joint extraction and preparation method of sea shrimp compound polypeptide

[0059] (1) Experimental design and preparation method for extraction and preparation of sea shrimp compound polypeptide by acid hydrolysis

[0060] According to the requirements of the experimental design, accurately take a certain amount of fresh sea shrimp, wash and drain; add a certain amount of pre-cooled homogenate, and then immediately place it in a tissue homogenizer for homogenization; Weigh and record it; then, an orthogonal experiment with four factors and three levels can be carried out (as shown in Table 1).

[0061] Table 1L9-3-4 Orthogonal Table (Software: Orthogonal Design Assistant II v3.1)

[0062]

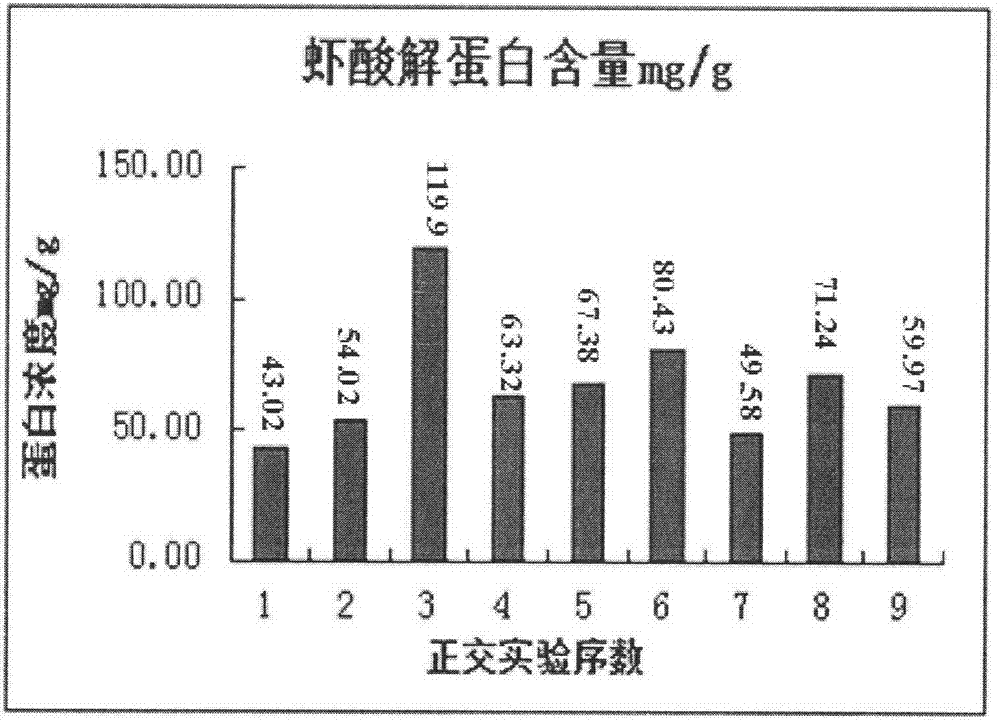

[0063] Utilize the software of orthogonal design assistant IIv3.1 to design the L9(34) orthogonal experiment, each experimental group is repeated three times: first, take 9 50mL beakers that have been decontaminated and dried, in order to ensure that the operating vo...

Embodiment 2

[0087] Example 2: Analysis and identification of the sea shrimp complex polypeptide extracted and prepared in Example 1.

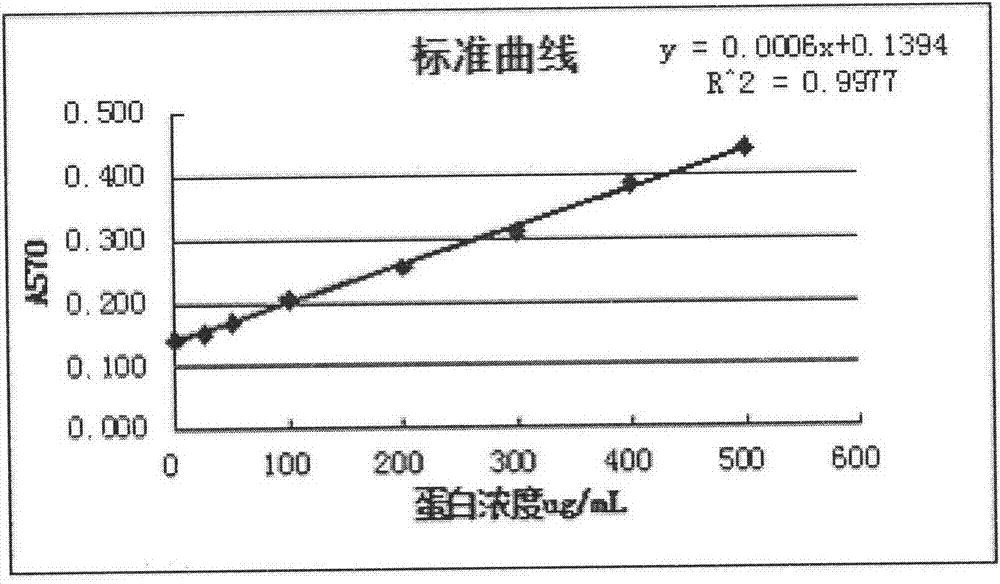

[0088] Principle of protein content determination: protein in food is decomposed under catalytic heating conditions, and the ammonia produced combines with sulfur to form ammonium sulfate. Ammonia is freed by alkalization distillation, absorbed by boric acid and then titrated with standard titration solution of sulfuric acid or hydrochloric acid, and the protein content is obtained by multiplying the consumption of acid by the conversion factor.

[0089] Determination principle of acid-soluble protein content: high-molecular-weight proteins in the sample are easily precipitated under acidic conditions, and protein hydrolyzates (acid-soluble proteins) with relatively small molecular weights can be dissolved in acidic solutions (including peptides and free amino acids.) Samples After acidification, the content of acid-soluble protein in the filtrate minus th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com