Machine-made sand concrete and its preparation method

A technology of machine-made sand and concrete, applied in the field of concrete, can solve the problems of increasing concrete shrinkage, large adsorption capacity, and reducing strength, etc., and achieves the effects of improving overall compressive strength, increasing contact area, and improving crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

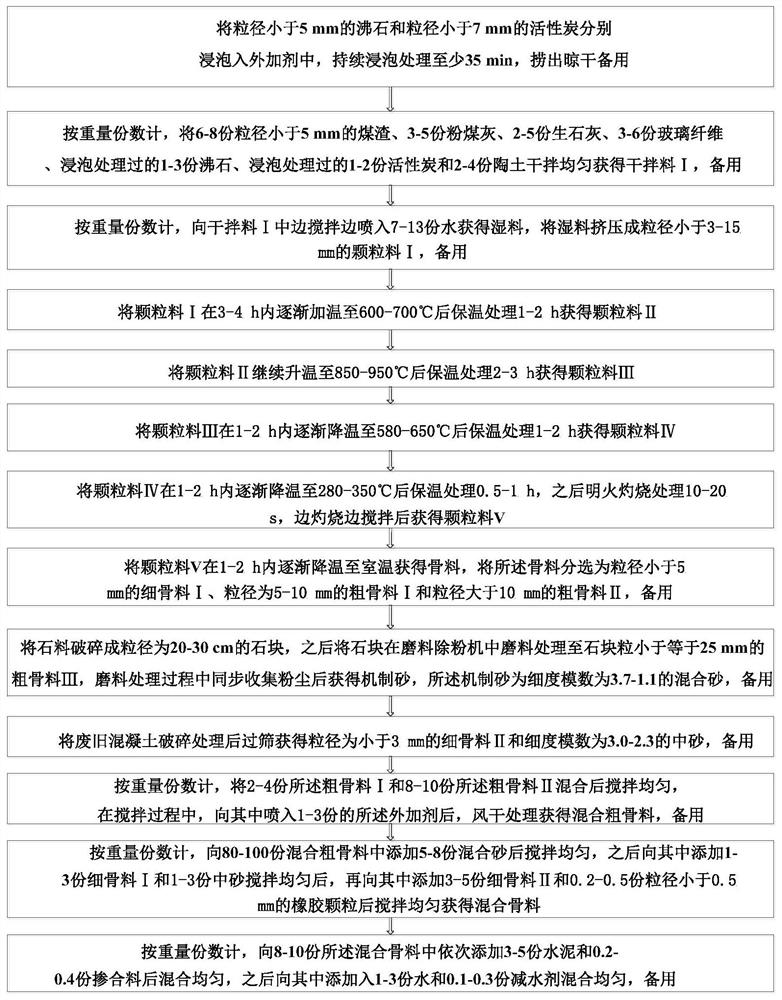

[0057] like figure 1 As shown, the invention provides a kind of preparation method of machine-made sand concrete, comprises the following steps:

[0058] Step 1. Soak the zeolite with a particle size of less than 4mm and the activated carbon with a particle size of less than 6mm into the polycarboxylate superplasticizer respectively, continue soaking for 35 minutes, remove and dry for later use;

[0059] Step 2, in parts by weight, 8 parts of coal cinders with a particle diameter of 4mm, 5 parts of fly ash, 5 parts of quicklime, 6 parts of glass fibers, 3 parts of zeolite soaked, 2 parts of gac and 4 parts of soaked treated Dry mix one part of pottery clay evenly to obtain dry mix I, set aside;

[0060] Step 3: In parts by weight, spray 13 parts of water into the dry mix I while stirring to obtain a wet mix, and extrude the wet mix into granular material I with a particle size of 4-15mm for later use;

[0061] Step 4: Gradually heat the granular material I to 700°C within 4 ...

Embodiment 2

[0076] The machine-made sand concrete prepared by the preparation method of the machine-made sand concrete of embodiment 1.

[0077] The properties of the machine-made sand concrete are shown in Table 1 (tested by conventional methods in this field).

Embodiment 3

[0079] like figure 1 As shown, the invention provides a kind of preparation method of machine-made sand concrete, comprises the following steps:

[0080] Step 1. Soak the zeolite with a particle size of 3mm and the activated carbon with a particle size of 5mm into the polycarboxylate superplasticizer respectively, continue soaking for 45 minutes, remove and dry for later use;

[0081] Step 2, in parts by weight, 7 parts of coal cinders with a particle diameter of 3mm, 4 parts of fly ash, 4 parts of quicklime, 4 parts of glass fibers, 2 parts of zeolite soaked, 2 parts of gac and 3 parts of soaked treated Dry mix one part of pottery clay evenly to obtain dry mix I, set aside;

[0082] Step 3: In parts by weight, spray 9 parts of water into the dry mix I while stirring to obtain a wet mix, and extrude the wet mix into granular material I with a particle size of 3-11mm for later use;

[0083] Step 4: Gradually heat the granular material I to 670°C within 3.5 hours, and then hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com