Preparation method of reinforced magnesium matrix composite

A composite material and reinforcing phase technology, which is applied in the field of preparation of reinforced magnesium matrix composite materials, can solve the problem of uneven distribution of reinforcing phase, poor interface reaction between reinforcing phase and magnesium matrix, and inconsistency in structural design of carbon nanotube-alumina composite reinforcing phase. It can achieve the effect of stable physical and chemical properties, good degree of graphitization and structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

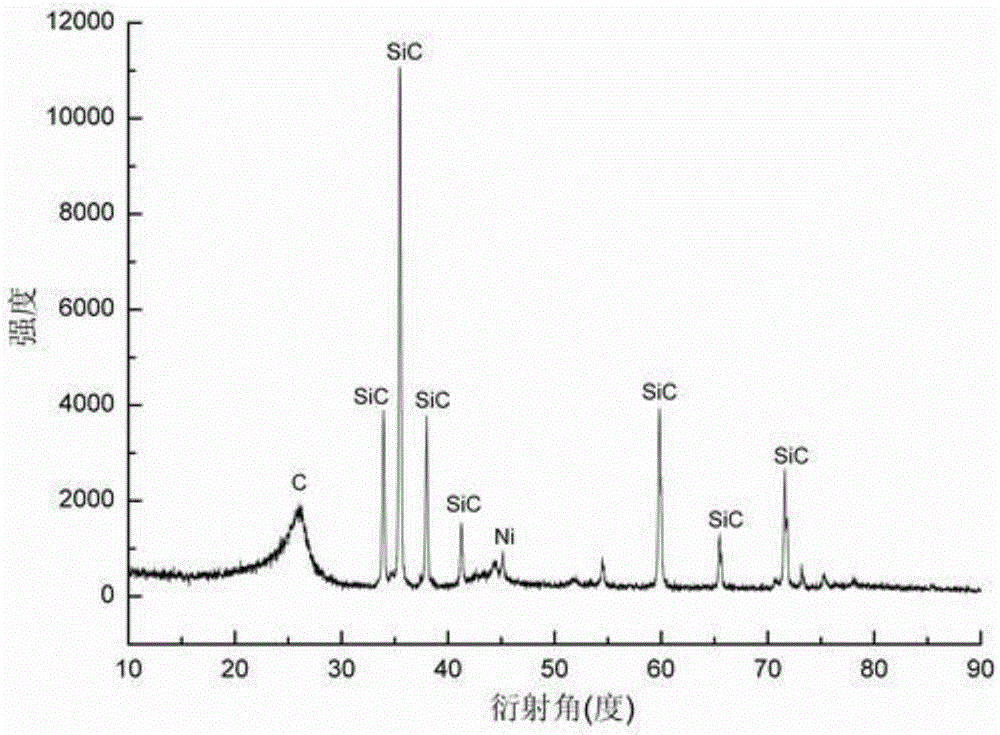

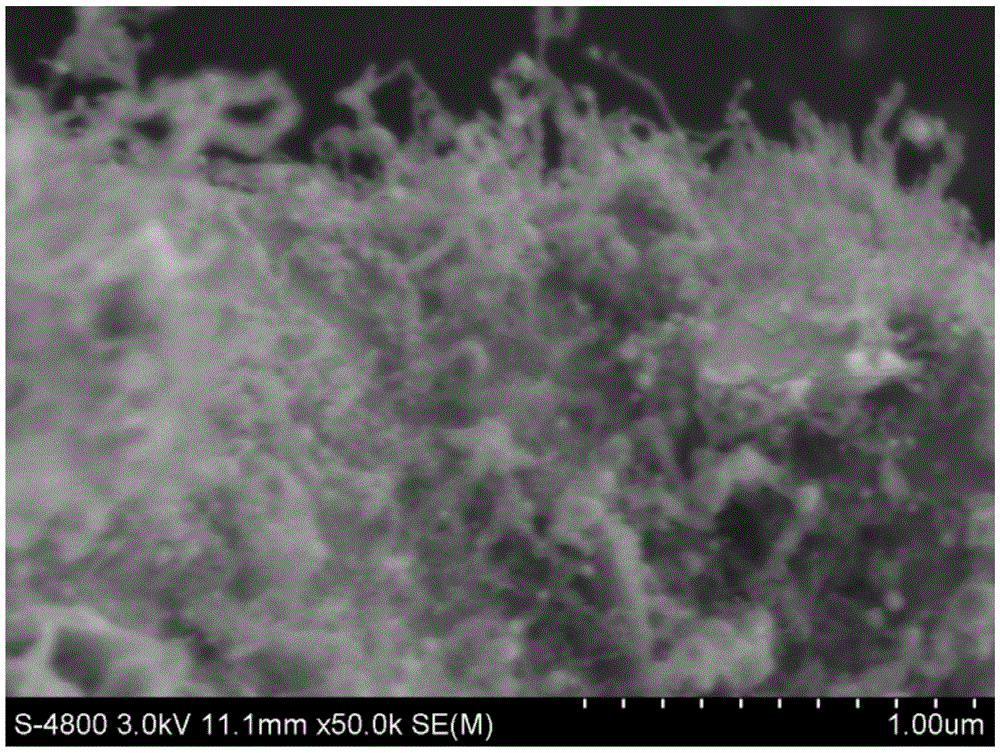

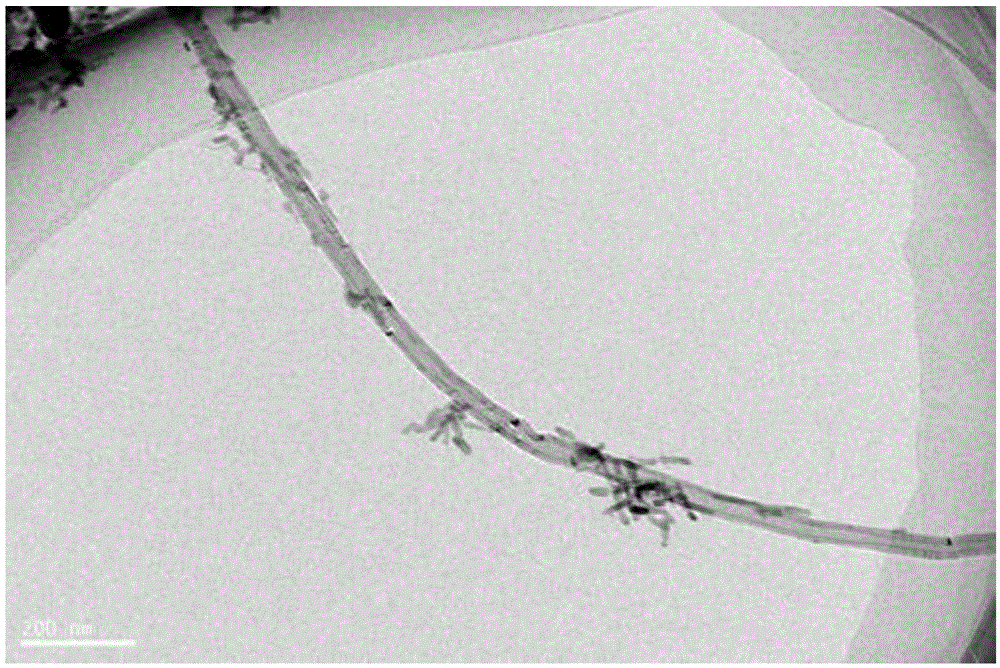

[0029] The first step, the preparation of carbon nanotube-silicon carbide in-situ composite reinforcement phase:

[0030] Add nickel acetate to ethylbenzene to ensure that the concentration of nickel acetate in ethylbenzene is 0.2g / mL, use a magnetic stirrer to stir the above liquid at a speed of 350r / min for 5min, so that nickel acetate is fully dissolved in ethylbenzene to prepare To obtain the ethylbenzene solution of nickel acetate, the required amount of silicon carbide particles with a particle size of 20nm is placed in a quartz ark, and the quartz ark is placed in the constant temperature zone of a horizontal tube furnace, and the tube furnace is closed by a vacuum pump. The vacuum at the place of the quartz ark reaches -0.1MPa, then feeds hydrogen into the tube furnace with a flow rate of 550mL / min, and feeds argon into the tube furnace with a flow rate of 400mL / min simultaneously, and the The temperature of the tube furnace was raised to 700°C, and the argon gas was t...

Embodiment 2

[0041] The implementation conditions and process of this embodiment are the same as in Example 1, except that the mass ratio of carbon nanotube-silicon carbide in-situ composite reinforcement phase to magnesium powder is 0.2:1 in the second step, and the carbon nanotube-silicon carbide Silicon hybrid reinforced magnesium-based composite material, wherein the magnesium-based composite material has a mass percent content of carbon nanotubes of 0.783 percent and a mass percent content of silicon carbide of 15.883 percent.

Embodiment 3

[0043] The first step, the preparation of carbon nanotube-silicon carbide in-situ composite reinforcement phase:

[0044] Add nickel acetate to ethylbenzene to ensure that the concentration of nickel acetate in ethylbenzene is 1.0g / mL, use a magnetic stirrer to stir the above liquid at a speed of 650r / min for 20min, so that nickel acetate is fully dissolved in ethylbenzene to prepare To obtain the ethylbenzene solution of nickel acetate, the required amount of silicon carbide particles with a particle diameter of 100nm is placed in a quartz ark, the quartz ark is placed in the constant temperature zone of a horizontal tube furnace, and the tube furnace is closed by a vacuum pump. The vacuum at the place where the quartz ark is located reaches -0.05MPa, then feeds hydrogen into the tube furnace at a flow rate of 1000mL / min, and feeds argon into the tube furnace at a flow rate of 1000mL / min at the same time, and the The temperature of the tube furnace was raised to 1100°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com