Airtightness automatic test system and test method

An automatic test system and air-tightness testing technology, applied in the direction of using liquid/vacuum for liquid-tightness measurement, and by measuring the acceleration and deceleration rate of fluid, etc. Less problems, to shorten the time of air tightness test, improve the level and accuracy, and ensure the effect of traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

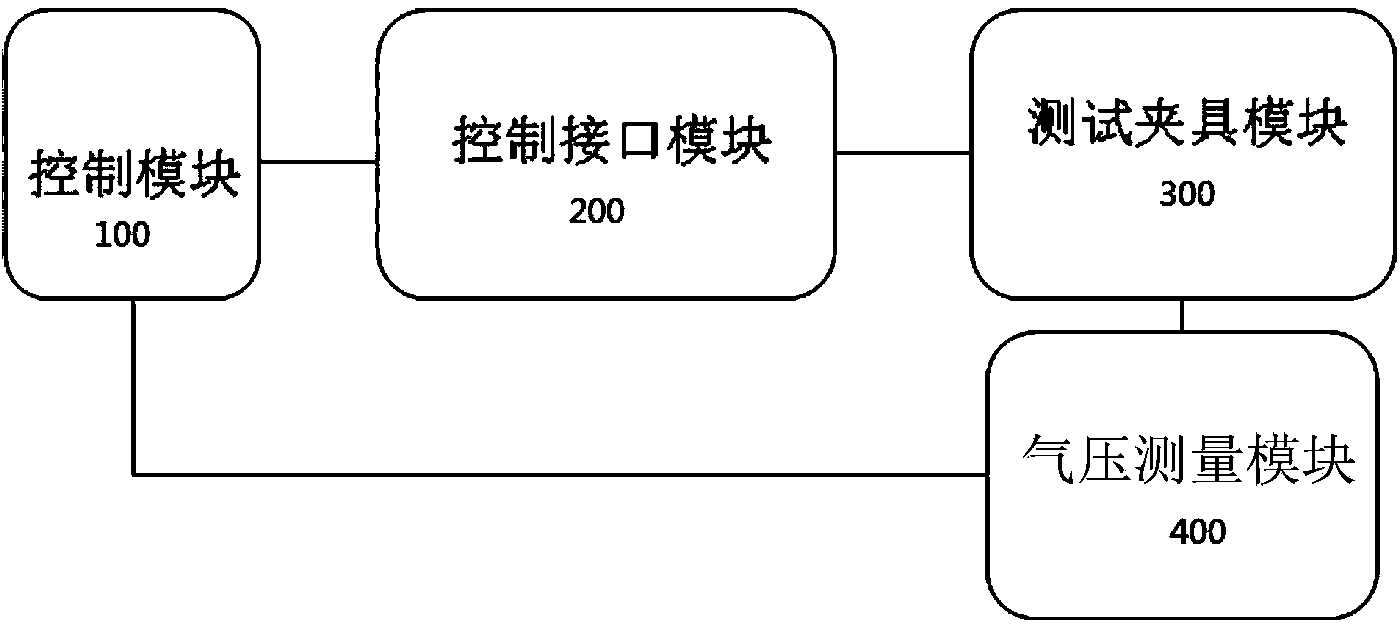

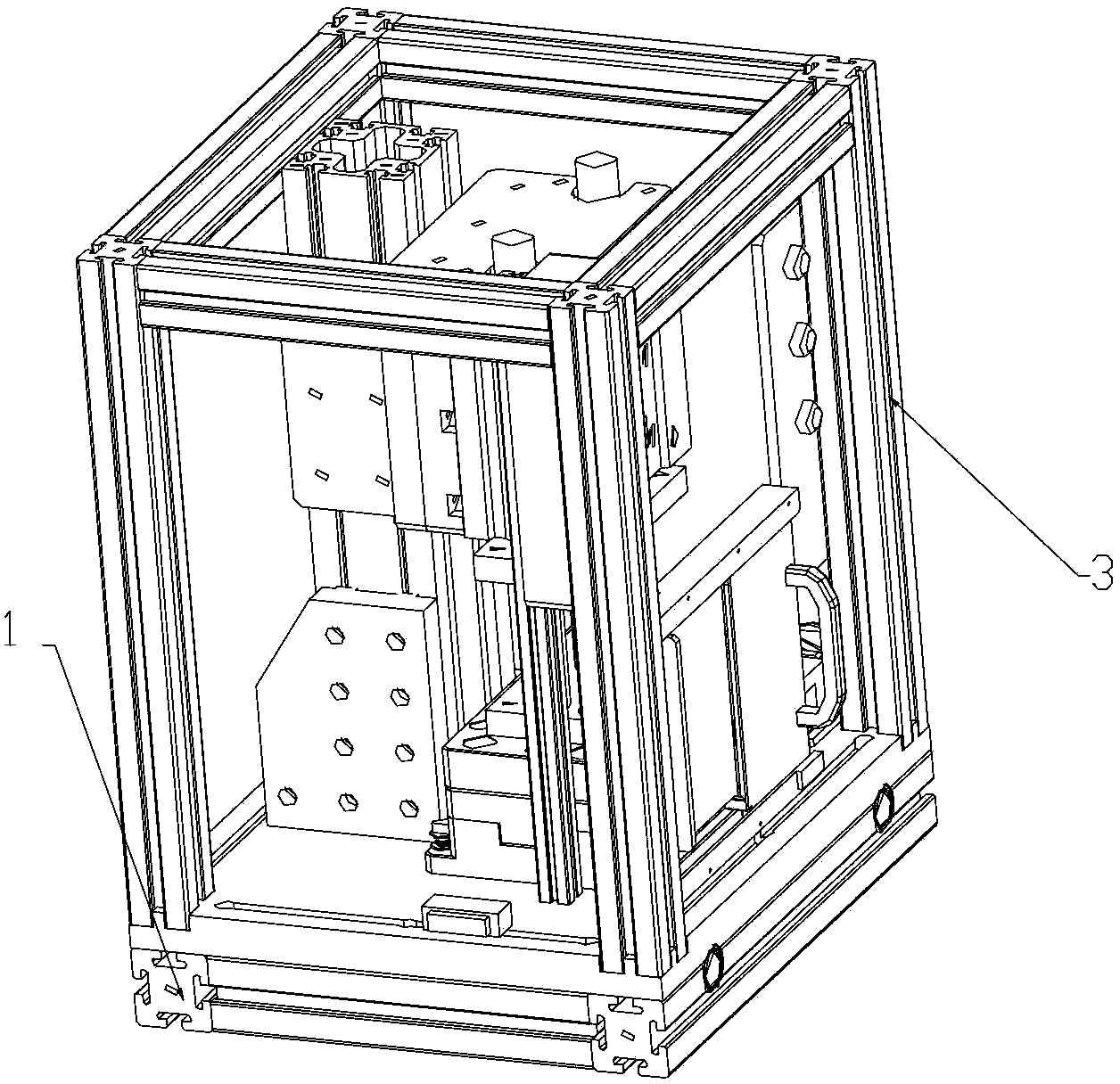

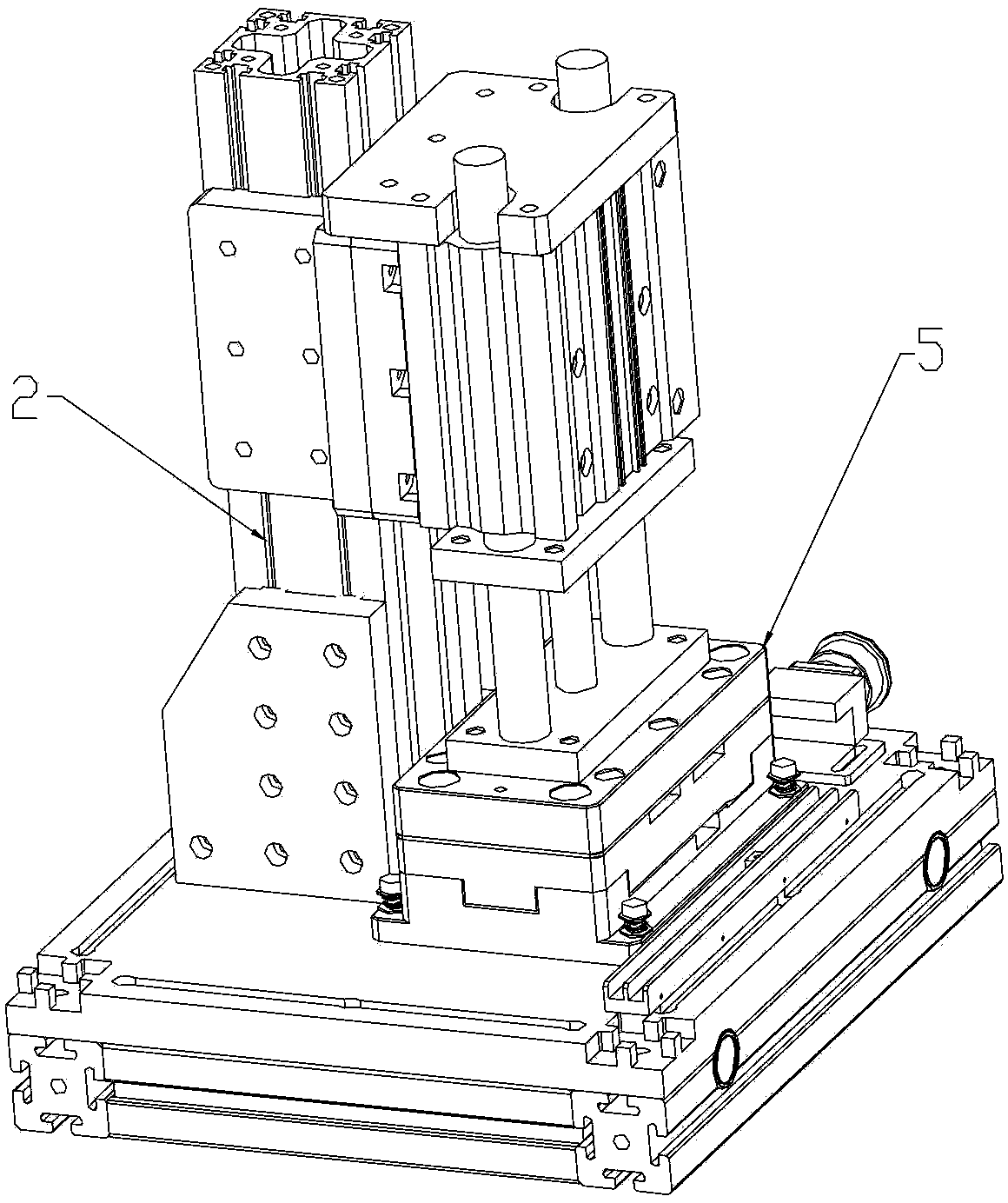

[0037] refer to figure 1 As shown, the present invention provides an automatic airtightness test system, which includes: a control module 100 for integrated control of the work of each functional module; a control interface module 200 for communicating with the control module 100; a test fixture module 300 for Communicatively connected with the control interface module 200; the air pressure measurement module 400 is respectively communicatively connected with the test fixture module 300 and the control module 100; For air pumping detection, the air pressure value is read from the test fixture module 300 through the air pressure measurement module 400, and the leakage measurement value calculated according to the current air pressure value in each specified time period is compared with the set maximum leakage amount, according to The time-period comparison result is fed back to the control module 100 and the test detection result is output. Among them, the relationship between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com