Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

A beneficiation method and feldspar ore technology, applied in flotation, chemical instruments and methods, magnetic separation, etc., can solve the problem that the whiteness of the product can only reach 40-50%, and achieve high grinding efficiency and large production capacity. , The effect of convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

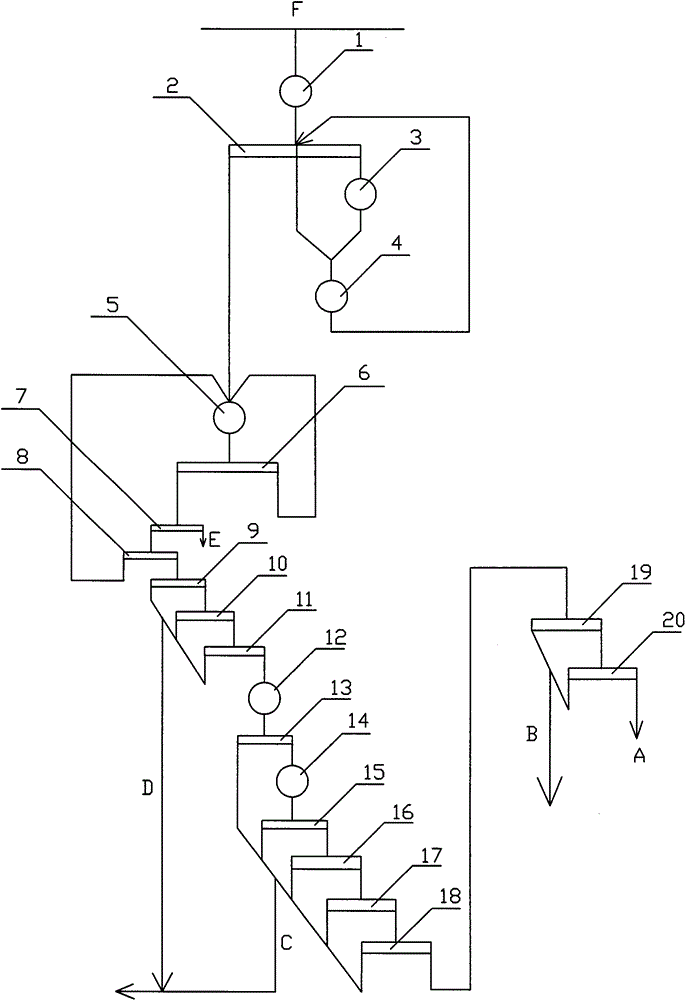

[0022] A beneficiation method that uses strong magnetic flotation to remove impurities in feldspar ore. The beneficiation method includes: crushing-ball milling-screening-desliming-strong magnetic-flotation-concentration and dewatering. The specific beneficiation method is as follows:

[0023] A. The raw ore F is crushed by the first-stage jaw crusher 1 and then enters the double-layer vibrating screen 2. After crushing, the raw ore F that reaches the ball milling standard enters the ball mill 5 for grinding, and the unqualified raw ore F enters the double-layer vibrating screen 2 respectively The secondary jaw crusher 3 and the cone crusher 4 continue to crush. The raw ore F that enters the secondary jaw crusher 3 is crushed and then enters the cone crusher 4 to continue crushing. The raw ore F after being crushed in the cone crusher 4 is again Enter the double-layer vibrating screen 2, and then enter the ball mill 5 to grind ore after reaching the ball mill standard.

[0024] B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com