Hole-digging acid liquor additive for reducing suede difference of polycrystalline black silicon made wool and application thereof

An additive and polysilicon technology, which is applied in the growth of polycrystalline materials, after treatment, and crystal growth, etc., can solve the problems of the uniformity of submicron suede structure, the appearance of polycrystalline black silicon solar cells and the efficiency of modules, etc., to achieve Effects of reduced etching rate, reduced surface tension, and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) The specific process steps of pre-cleaning:

[0081] Step 1: In the acid and alkali tank according to concentrated H 2 SO 4 (95wt%): H 2 o 2 (30wt%) volume ratio is 3:1 configuration reaction solution;

[0082] Step 2: immerse the polysilicon wafer in the above reaction solution and boil for 30 minutes;

[0083] Step 3: configure 2wt% HF solution in the acid and alkali resistant tank;

[0084] Step 4: Submerge the polysilicon wafer in the above HF solution for 300s;

[0085] (2) Concrete process steps of coarse alkali throwing:

[0086] Step 1: configure a KOH solution with a concentration of 9wt% in the acid and alkali resistant tank;

[0087] Step 2: Heat the solution to 80°C;

[0088] Step 3: immerse the polysilicon wafer in the above KOH solution and react for 210s;

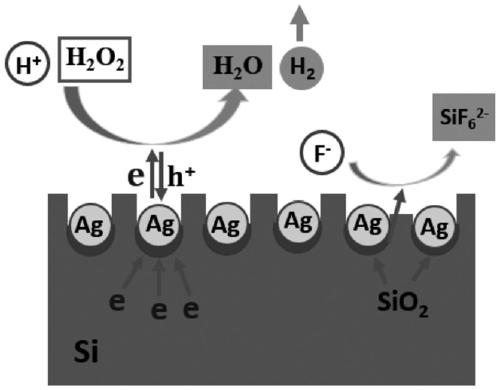

[0089] (3) Specific process steps of silver plating:

[0090] Step 1: Configure 0.6wt% HF and 1.4×10 -3 wt% AgNO 3 The mixed reaction solution;

[0091] Step 2: immerse the polysilicon...

Embodiment 2

[0110] On the basis of embodiment 1, the difference is:

[0111] In the concrete process step of described hole digging, the hole digging etchant is made of 10wt% H 2 o 2 , 4wt% HF and 1wt% hole-digging acid additive;

[0112] The hole-digging acid liquid additive is composed by weight percentage: 1 wt% of polyoxyethylene lauryl ether, 1.2 wt% of tartaric acid, 0.8 wt% of sodium alginate, 1 wt% of aspartic acid, and 2 wt% of triethylene glycol %, diethylene glycol monomethyl ether 1wt%, ultrapure water 93wt%.

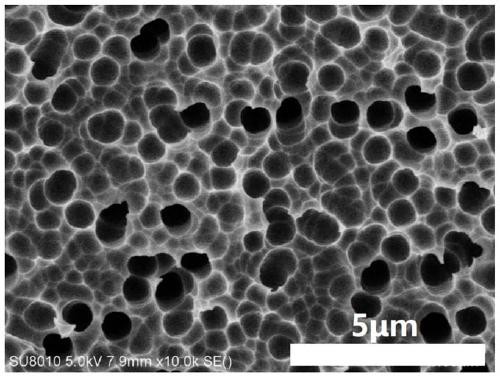

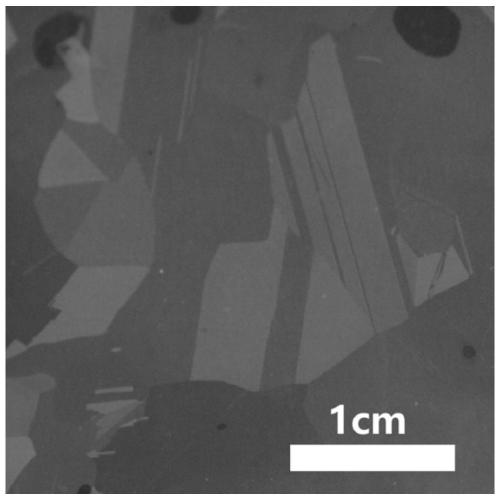

[0113] Finally, the appearance photo of polycrystalline black silicon is as follows: Figure 7 As shown, it can be seen that the use of polycrystalline black silicon pore-digging additives for texturing can effectively improve the crystal flower problem, the color difference between crystal planes with different orientations is small, and the textured surface is uniform. Such as Figure 8 As shown, a submicron meter-scale hemispherical texture is formed on the surf...

Embodiment 3

[0115] On the basis of embodiment 2, the difference is:

[0116] In the specific process steps of digging, the digging time is 180s;

[0117] In the specific process steps of hole expansion, the hole expansion time is 160s.

[0118] The finally obtained polycrystalline black silicon looks like Figure 11 As shown, the use of polycrystalline black silicon pore-digging additives for texturing can effectively solve the problem of crystal cracks after polycrystalline silicon texturing, and there is no difference in the texture of grains with different crystal orientations. Such as Figure 12 As shown, the surface SEM image of the polycrystalline black silicon prepared in Example 3 shows that the pore diameter of the polycrystalline black silicon after texturing is between 650 and 850 nm. Such as Figure 13 As shown, it can be seen from the SEM image of the polycrystalline black silicon section prepared in Example 3 that the submicron hole depth is between 350-600 nm. Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com