Film-picking and film-unloading mechanism for residual film recovery of straight-rod crops

A technology for recycling residual film and crops, which is applied to collectors, plant protection covers, agricultural machinery and implements, etc. It can solve problems such as difficulties, unreliable collection of residual film, cumbersome unloading of film, etc., and achieves low cost, simple structure, Reliable film removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

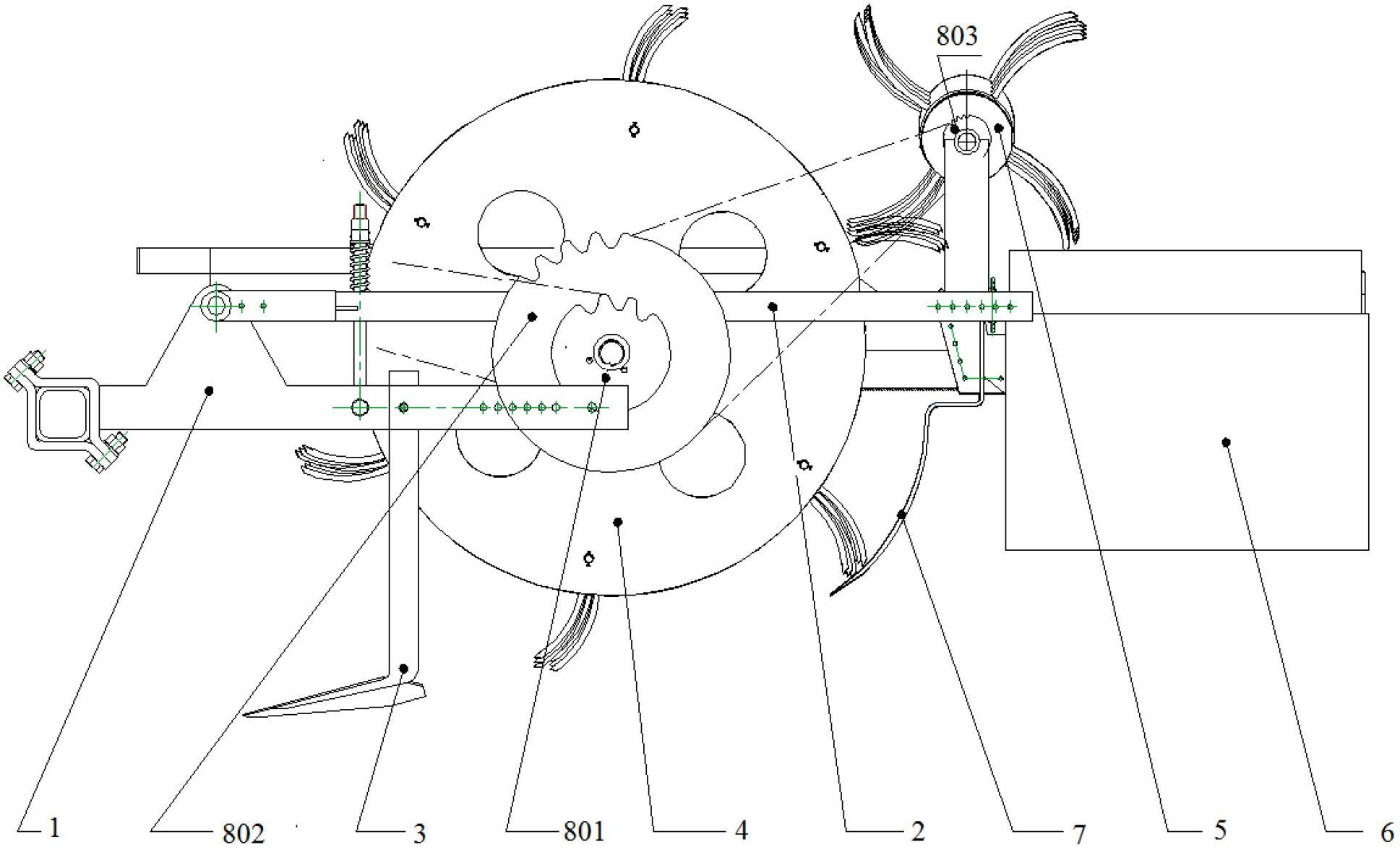

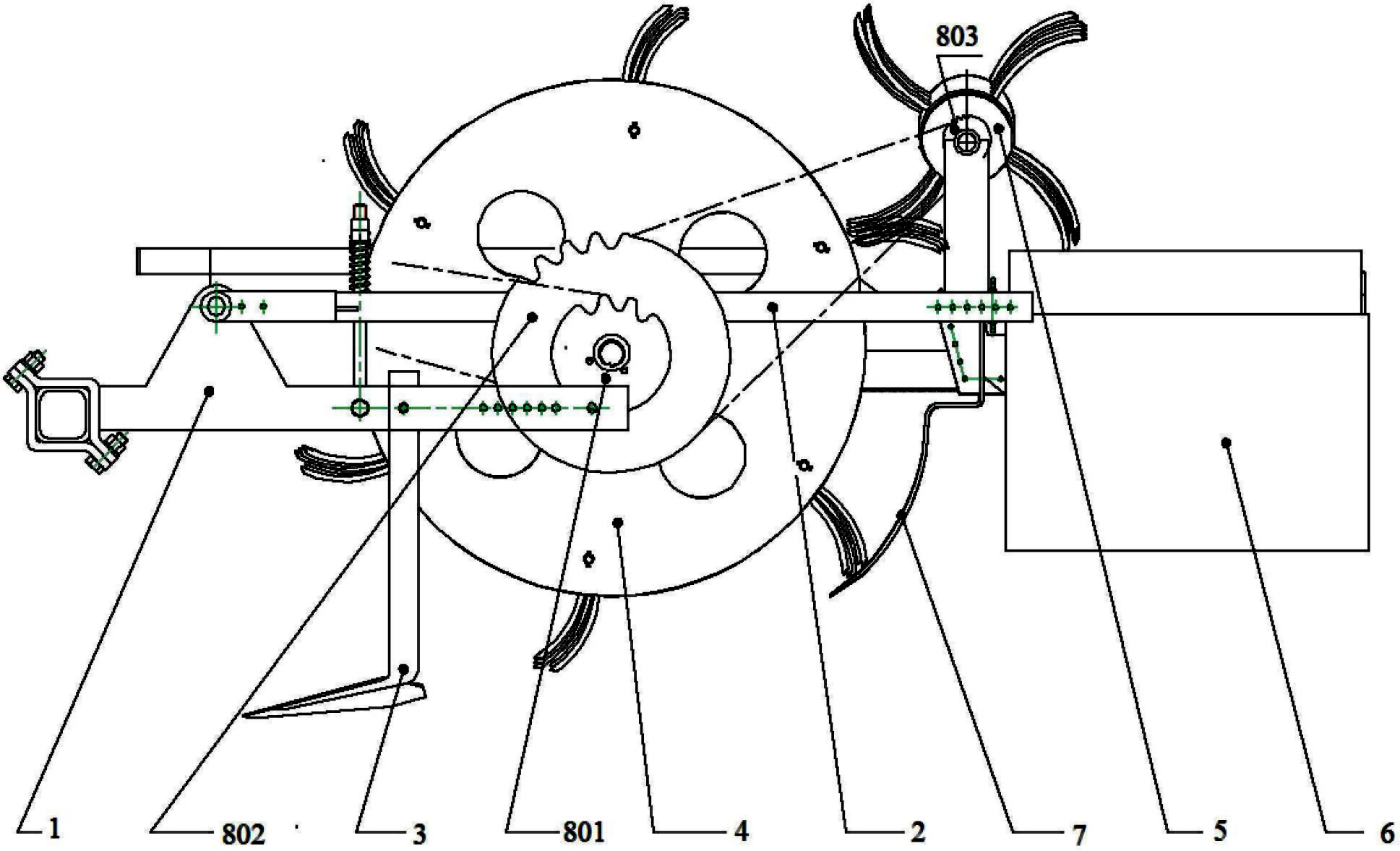

[0028] The present invention provides a mechanism for picking up and unloading residual film of straight-stem crops. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0029] In order to ensure smooth, stable and reliable retraction of the plastic film, to maintain a relatively complete plastic film, and to separate the soil and sundries, the main process of mechanical plastic film collection is designed as follows: loosening soil - film lifting - film picking - film debris Separation - stripping - membrane collection. Therefore, the main film collecting process of this mechanism is: edge film loosening soil - entering soil to lift film - picking up film - unloading film - collecting film. The edge film loosening is mainly done by the soil loosening shovel; the soil entry and film lifting is done by the film lifting shovel; the film picking is done by the film collecting wheel; the film unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com