Composite magnetic micro-sphere and method for preparing same

A composite magnetic and microsphere technology, which is applied in the preparation of microspheres, microcapsule preparation, magnetic properties of inorganic materials, etc., can solve the problems of limiting the application of magnetic-assisted separation technology, harsh preparation method conditions, complicated process flow, etc., and achieves easy and rapid prototyping. , good sphericity and coverage, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

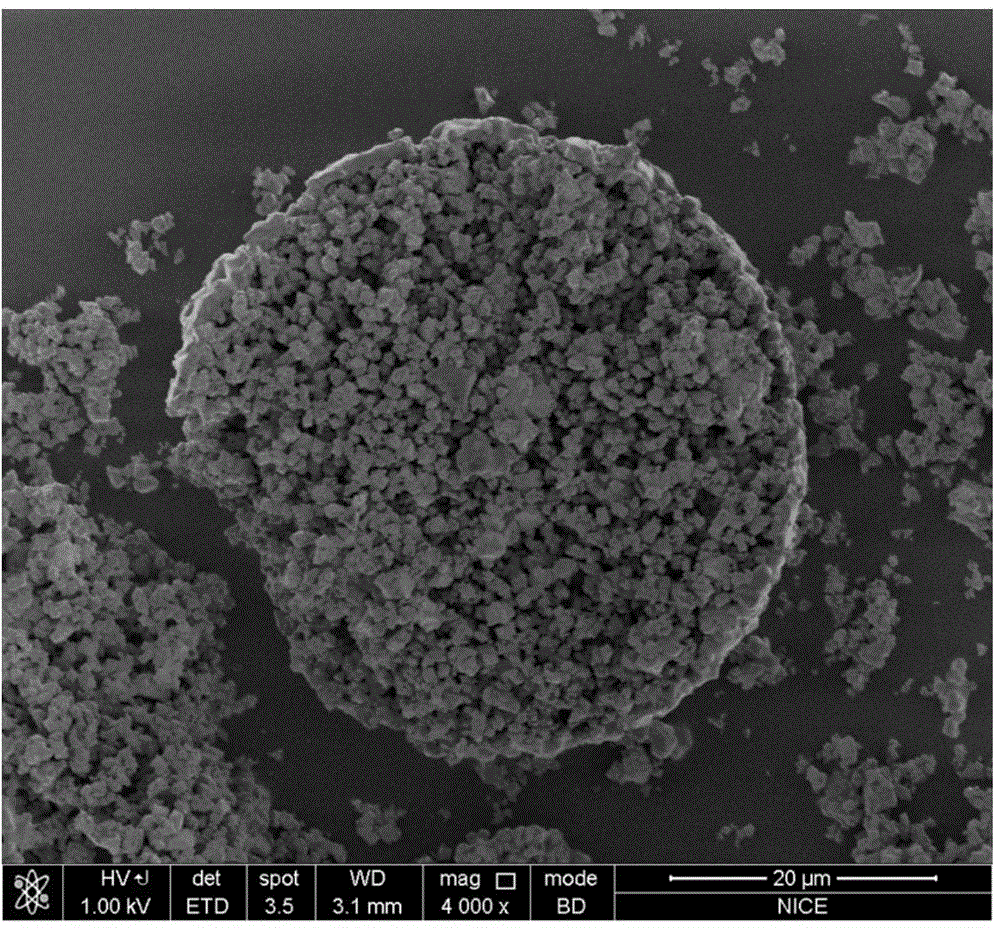

[0052] 60g of Fe with a particle size of 0.1μm 3 o 4 The powder was dispersed in 1600ml of ethanol, 400ml of deionized water and 45ml of concentrated ammonia water mixture, 1g of sodium stearate was added, and 30g of methyl orthosilicate solution was added, reacted at room temperature, and stirred for 0.1h. Magnetic separation, wash the solid particles with ethanol and water respectively.

[0053] Add a certain amount of deionized water to the obtained solid particles to adjust the solid concentration to 5% by weight, add dilute nitric acid to adjust the pH value to 3, stir mechanically for 30 minutes, add 12 g of 40% by weight silica sol dropwise, and continue stirring for 30 minutes. The stirring speed was 400 rpm.

[0054] The obtained magnetic fluid slurry was transported into a spray drying device, controlled at an inlet temperature of 200°C and an outlet temperature of 100°C, and dried and formed; then baked at 280°C in an air atmosphere for 6 hours to obtain coated mi...

Embodiment 2

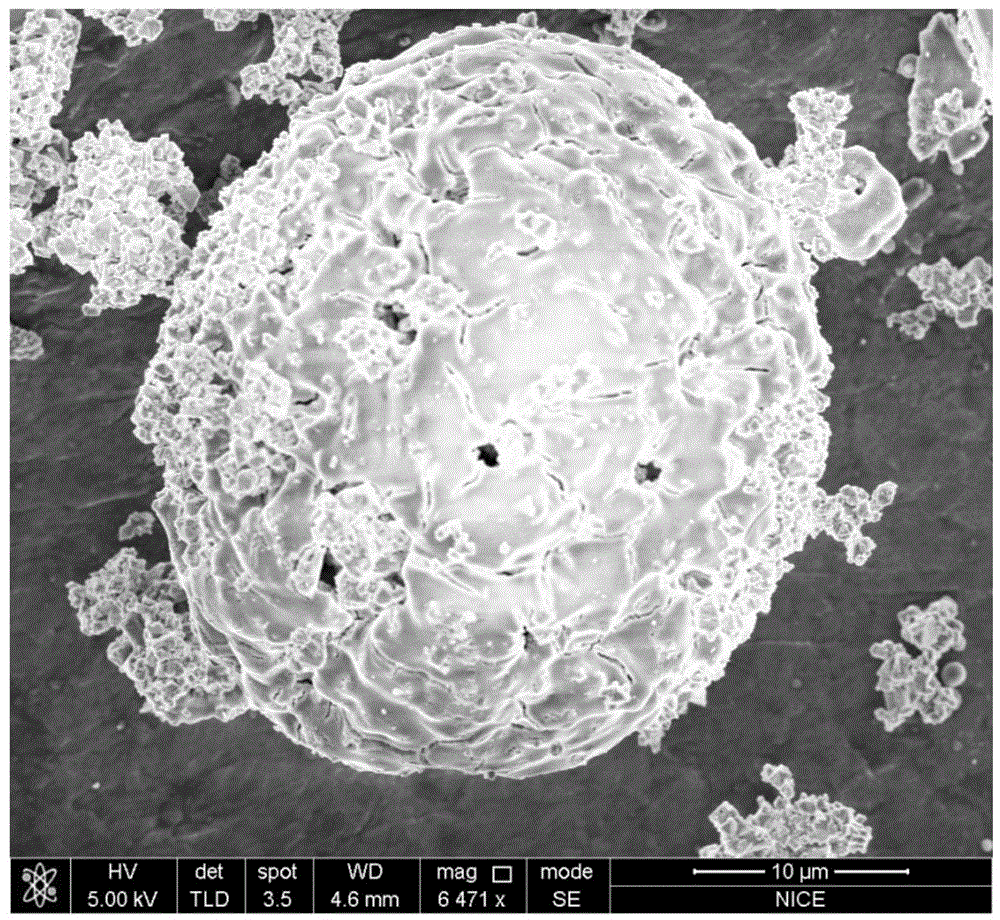

[0058] Weigh 60g of Fe with a particle size of 0.5μm 3 o 4 Powder, placed in 1000ml0.1molL -1 HNO 3 , ultrasonication for 10 min, magnetic separation, and washing with ethanol and deionized water, respectively.

[0059] Disperse the solid powder in 1600ml of ethanol, 400ml of deionized water and 25ml of 10% sodium hydroxide solution, add 1g of sodium dodecylsulfonate, add 40g of tetraethyl orthosilicate solution, react at 40°C, and stir for 2h. Magnetic separation, wash the solid particles with ethanol and water respectively.

[0060] Add a certain amount of deionized water to the obtained solid particles to adjust the solid concentration to 15% by weight, add dilute nitric acid to adjust the pH to 4, stir mechanically for 30 minutes, add 12 g of 40% by weight potassium silicate dropwise, and continue stirring for 30 minutes. The stirring speed was 750 rpm.

[0061] The obtained magnetic fluid slurry was transported into a spray drying device, and the inlet temperature wa...

Embodiment 3

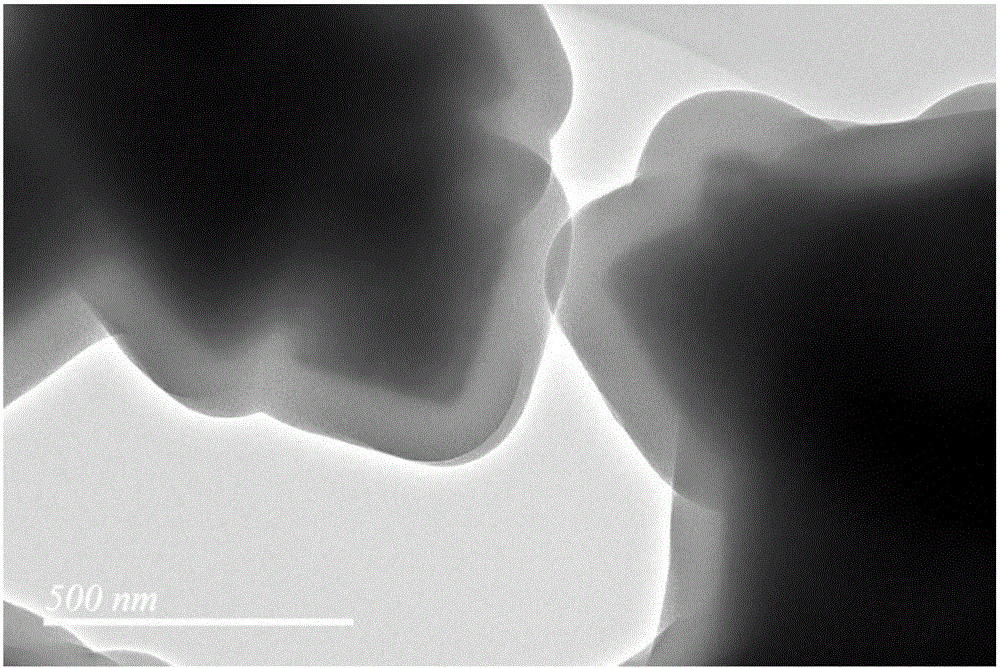

[0065] Disperse 60g of iron powder with a particle size of 1 μm in 1000ml of ethanol, 250ml of deionized water and 45ml of concentrated ammonia water mixture, add 1g of sodium dodecylbenzenesulfonate, add 50g of tetraethyl orthosilicate solution, react at 50°C, and stir 4h. Magnetic separation, wash the solid particles with ethanol and water respectively.

[0066] Add a certain amount of deionized water to the obtained solid particles to adjust the solid concentration to 25% by weight, add dilute nitric acid to adjust the pH value to 5, stir mechanically for 30 minutes, add 12 g of 40% by weight ethyl orthosilicate dropwise, and continue stirring for 30 minutes. The stirring speed was 1100 rpm.

[0067] The obtained magnetic fluid slurry was transported into a spray drying device, controlled at an inlet temperature of 300°C and an outlet temperature of 150°C, and then dried and formed; then baked at 400°C in an air atmosphere for 6 hours to obtain coated micro-nano composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com