End lead head forming device for steel wire rope

A forming device and steel wire rope technology, applied in the binding of ends, textiles and papermaking, textile cables, etc., can solve the problems of high cost, waste, unsuitable for home use, etc., and achieve the effect of rapid prototyping, simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

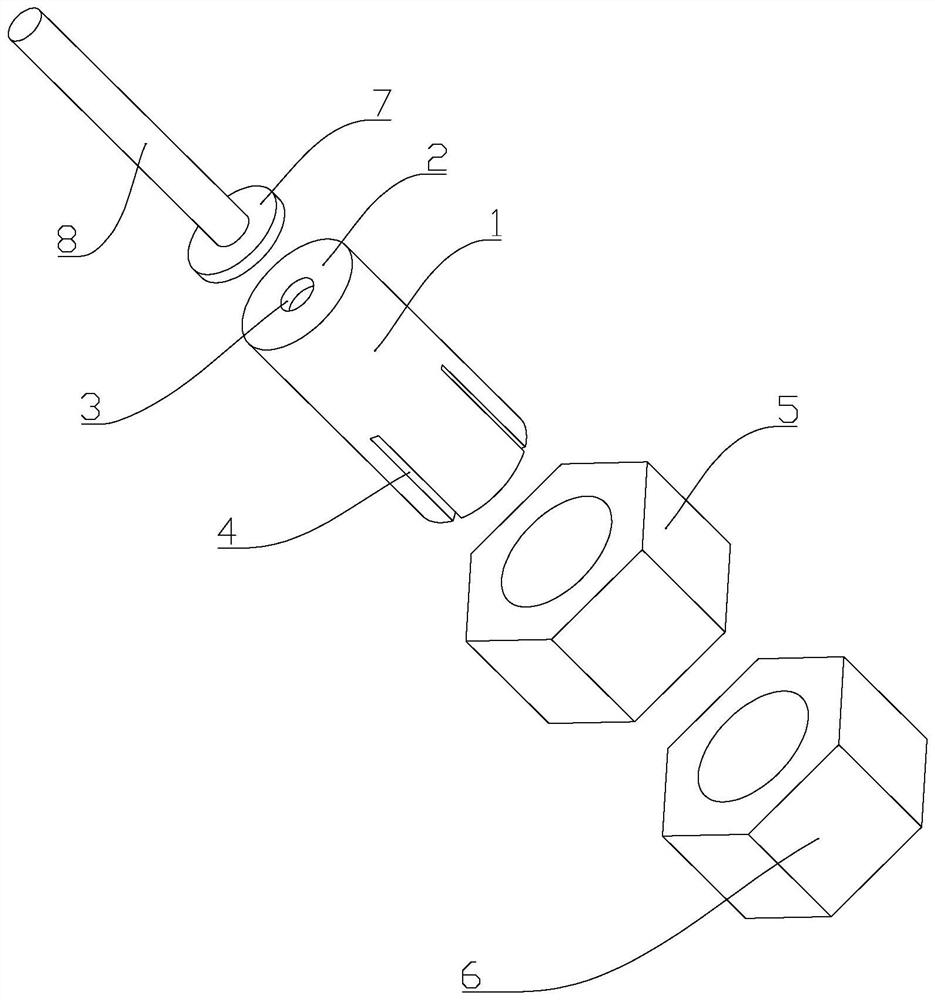

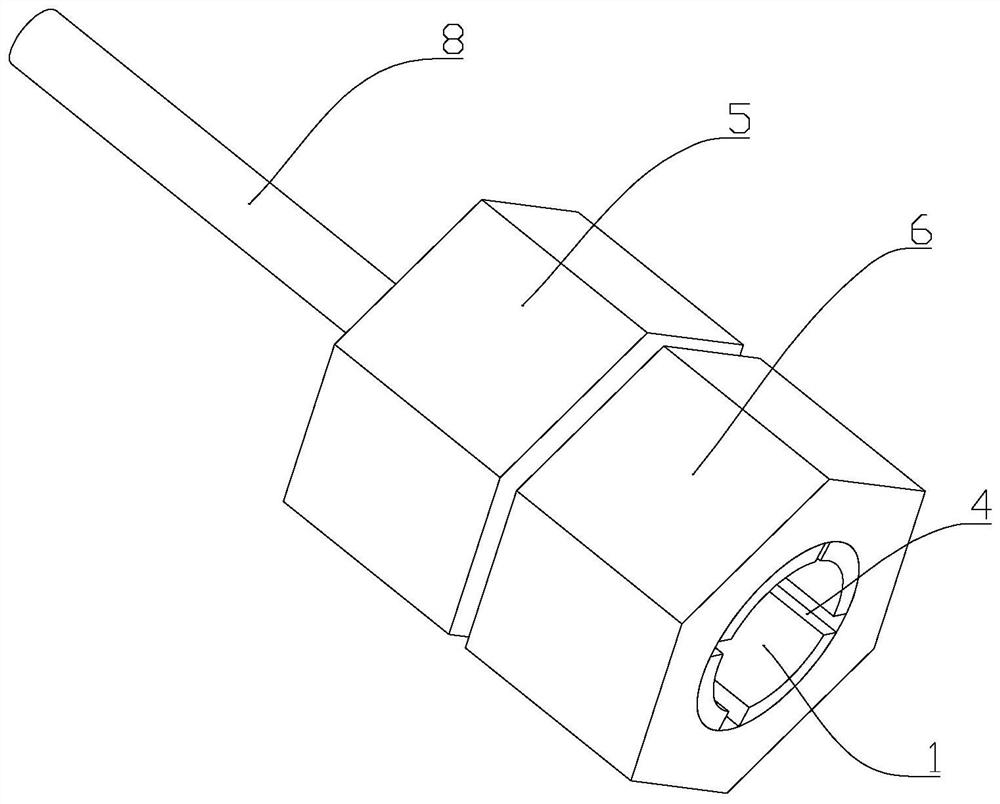

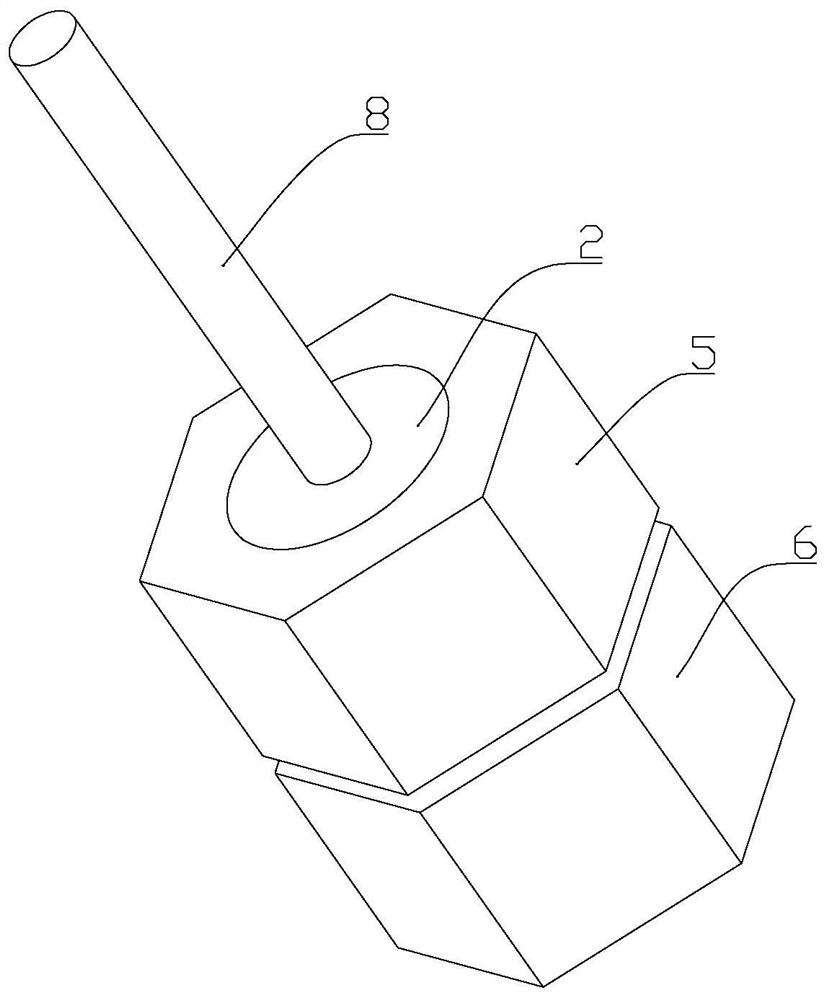

[0017] Such as figure 1 , 2 , 3, a lead forming device at the end of a steel wire rope, comprising a round tube 1, the outer arc surface of the round tube 1 is provided with threads, and one end of the round tube 1 is fixed with a sealing plate 2, the The center of the sealing plate 2 is provided with a through hole 3 coaxial with the round tube 1, and the other end of the round tube 1 relative to the sealing plate 2 is provided with at least one chute 4 in the axial direction of the round tube 1. The outer sides of the two ends of the tube 1 are respectively matched with a first nut 5 and a second nut 6, and the inside of the round tube 1 is provided with a top block 7 that slides axially along the round tube 1, and the top block 7 A push rod 8 is fixed at the end facing the sealing plate 2 in the center, and the push rod 8 is in clearance fit with the through hole 3 .

[0018] The other end of the round tube 1 relative to the sealing plate 2 is provided with four sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com