Vehicle sharp-corner square-pipe production line

A production line and sharp-edged technology, applied in the field of cold rolling, can solve the problems of not being able to form by hot rolling and forming by cold rolling, and achieve the effects of fast forming speed, low cost and quick effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

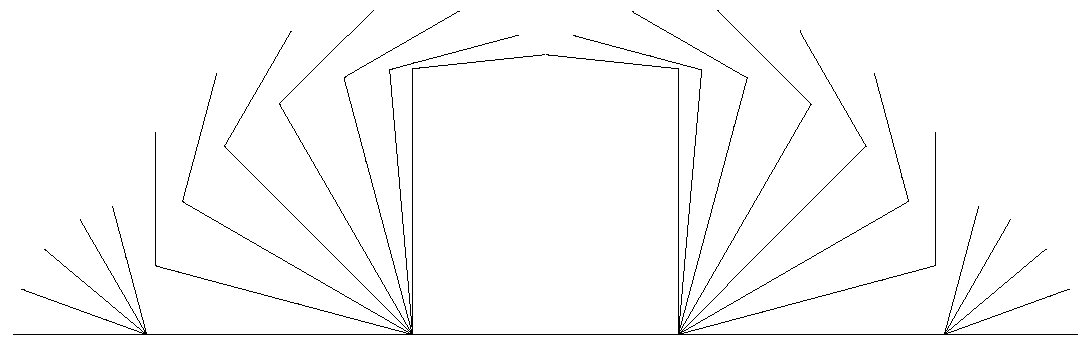

[0032] Such as Figure 1-6 shown.

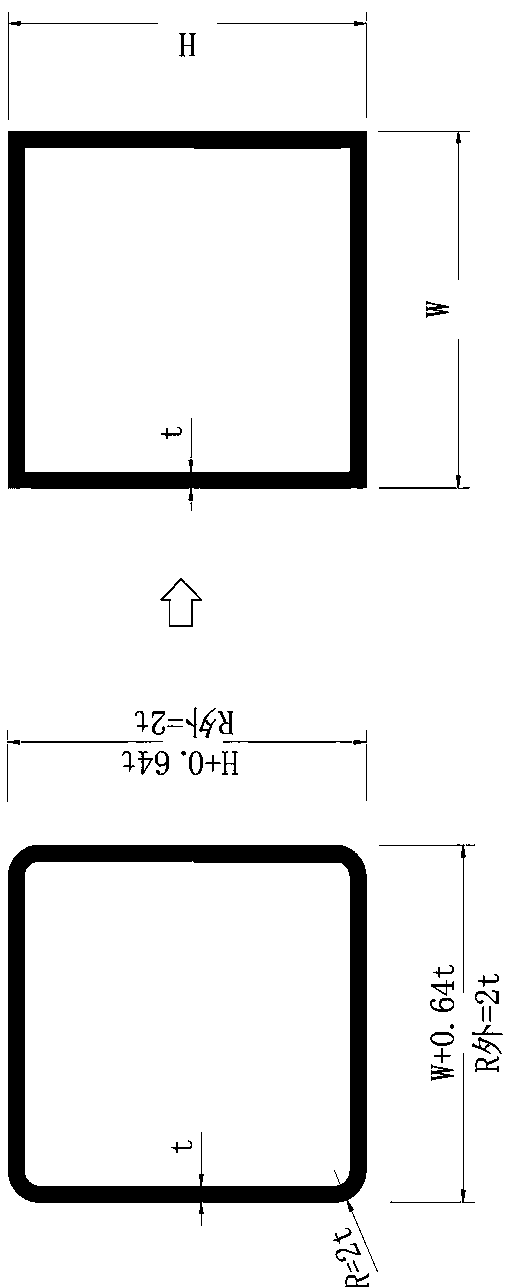

[0033] A sort of figure 1 In the square tube-shaped vehicle sharp-angled square tube production line shown, its four corners are right angles, and can also be sharp angles less than 90 degrees. Taking the right angle as an example, the production line of the present invention includes the following equipment:

[0034] A feeding machine 1, which will place the cut steel strip coil on the starting end of the cold rolling production line, which is exactly the same as the feeding machine of the existing cold extrusion production line;

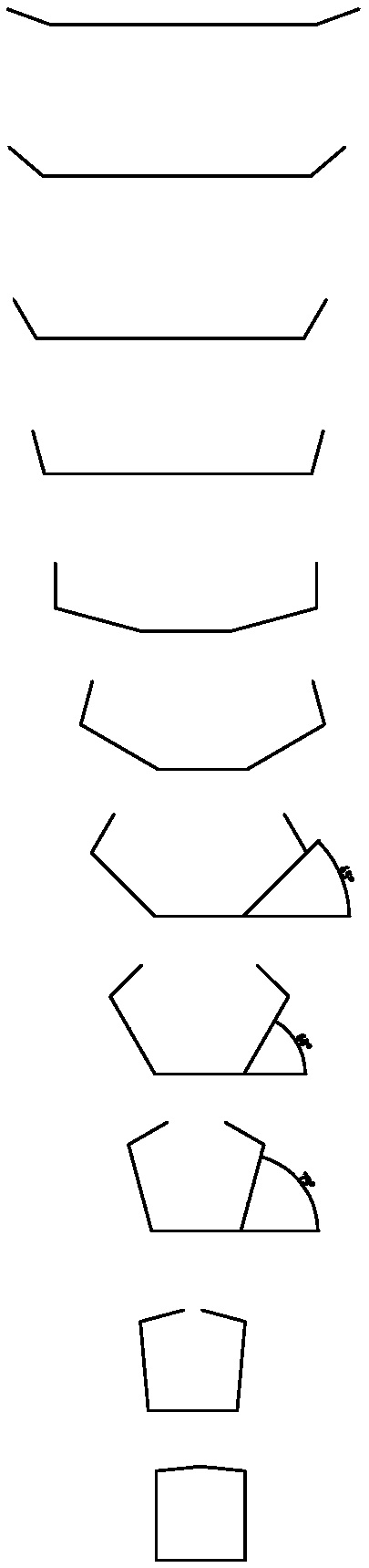

[0035] A preliminary forming roll unit 2, which is used to gradually roll the flat steel strip into a square tube shape, and the seam of the square tube is located at the uppermost center position; the structure of the preliminary forming roll unit is as follows image 3 As shown, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com