Prefabricated small box girder reinforcing steel bar tire membranization mounting device and method

A technology of installation device and small box girder, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of delayed construction period and long installation time of reinforced tire membrane, and achieve the effect of convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

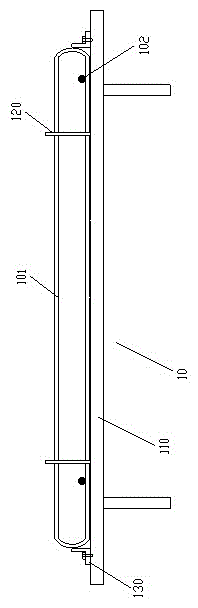

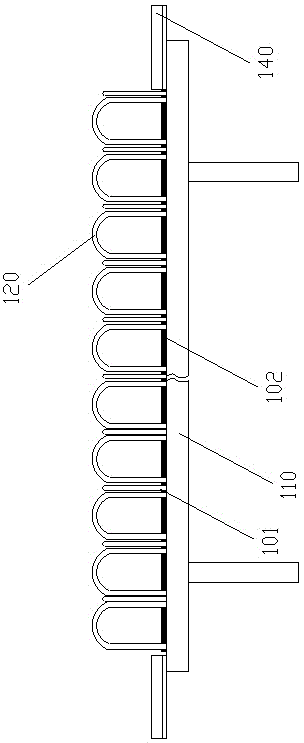

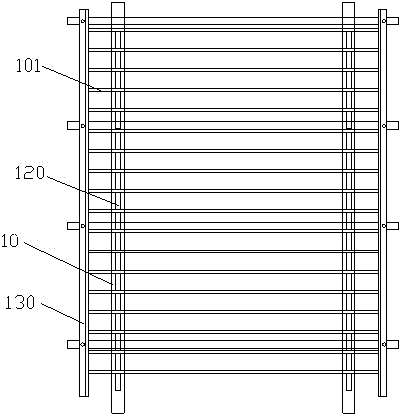

[0027] Such as Figure 1~6 As shown, a prefabricated small box girder steel bar membrane installation device is used to design, including a roof membrane 10 for prefabricating the roof reinforcement skeleton and a web membrane 20 for prefabricating the bottom plate and web reinforcement skeleton. The roof membrane 10 includes a support platform 110 for erecting the top steel bars, the upper surface of the support platform 110 is provided with a grid 120 for arranging the roof steel bars 101, and the two sides of the support platform 110 are provided with transverse reinforcement positioning plates 130 , the transverse reinforcement positioning plate 130 is fixedly connected to the support platform 110 via bolts.

[0028] In order to facilitate the adjustment of the transverse reinforcement positioning plate 130, the support platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com