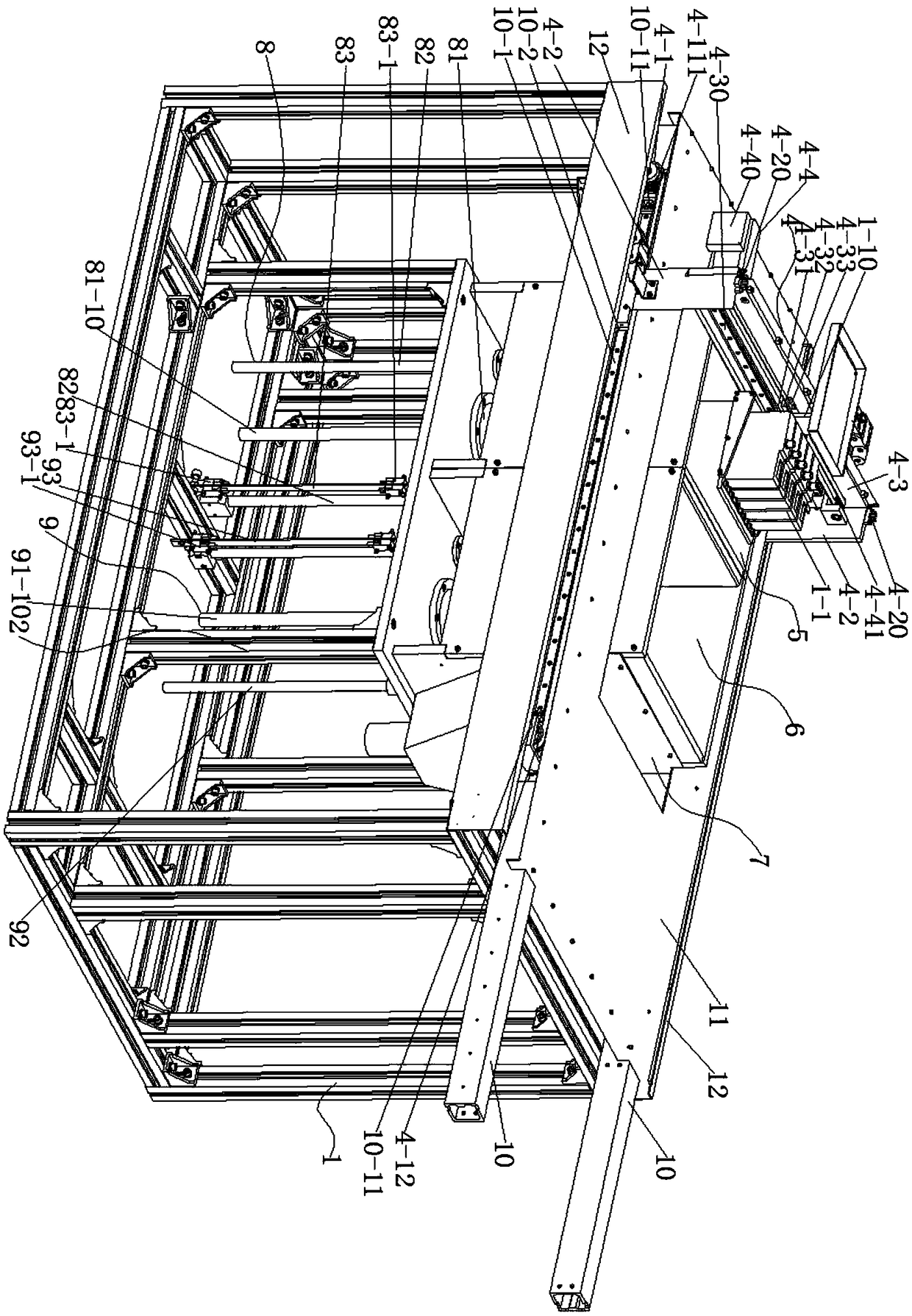

Sand mould 3D rapid molding equipment using slab printer

A technology of flatbed printers and molding equipment, applied in metal processing equipment, 3D object support structures, additive manufacturing, etc., can solve the problems of expensive and expensive materials, and achieve the effect of good particle size, particle size control, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

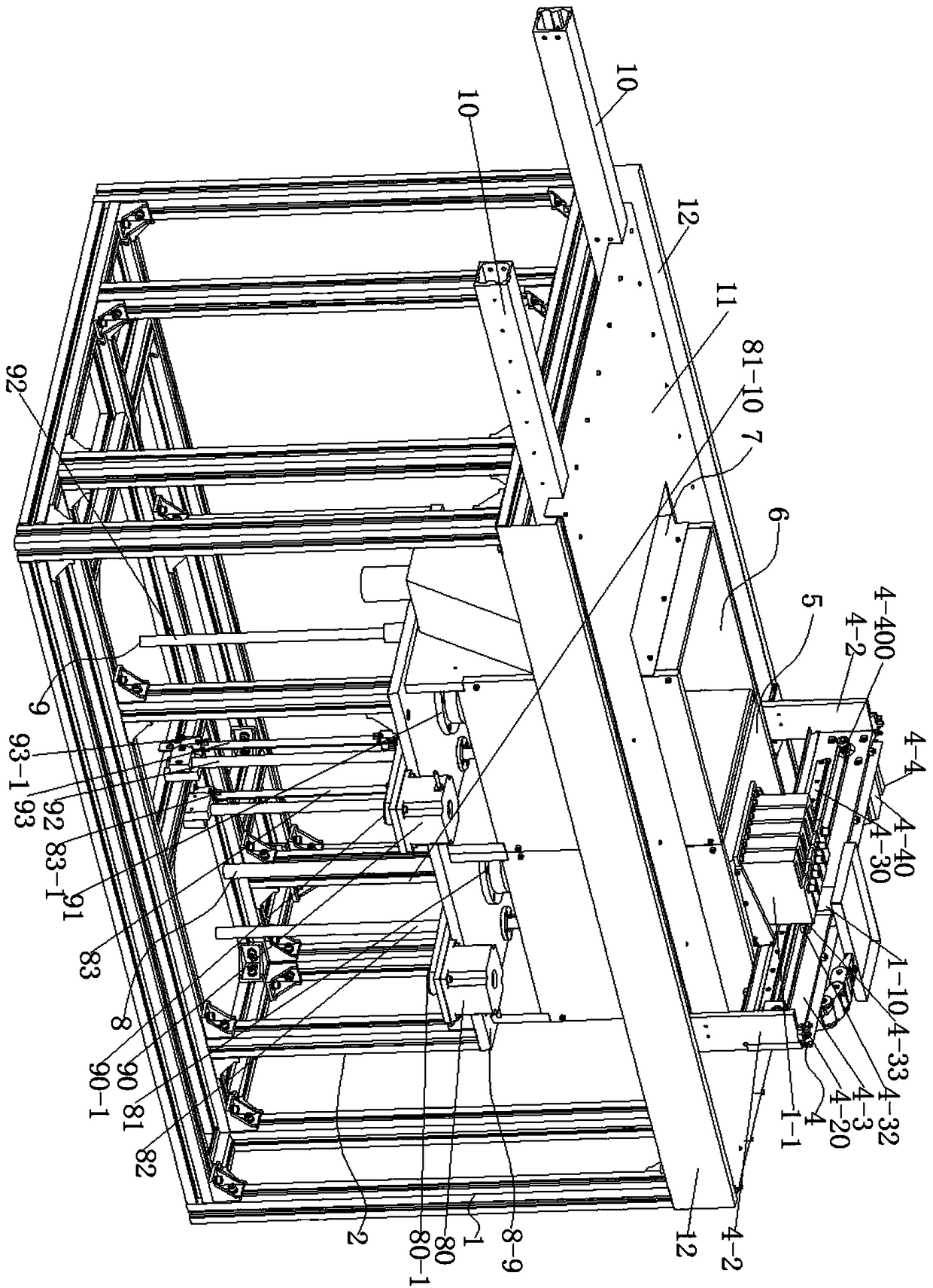

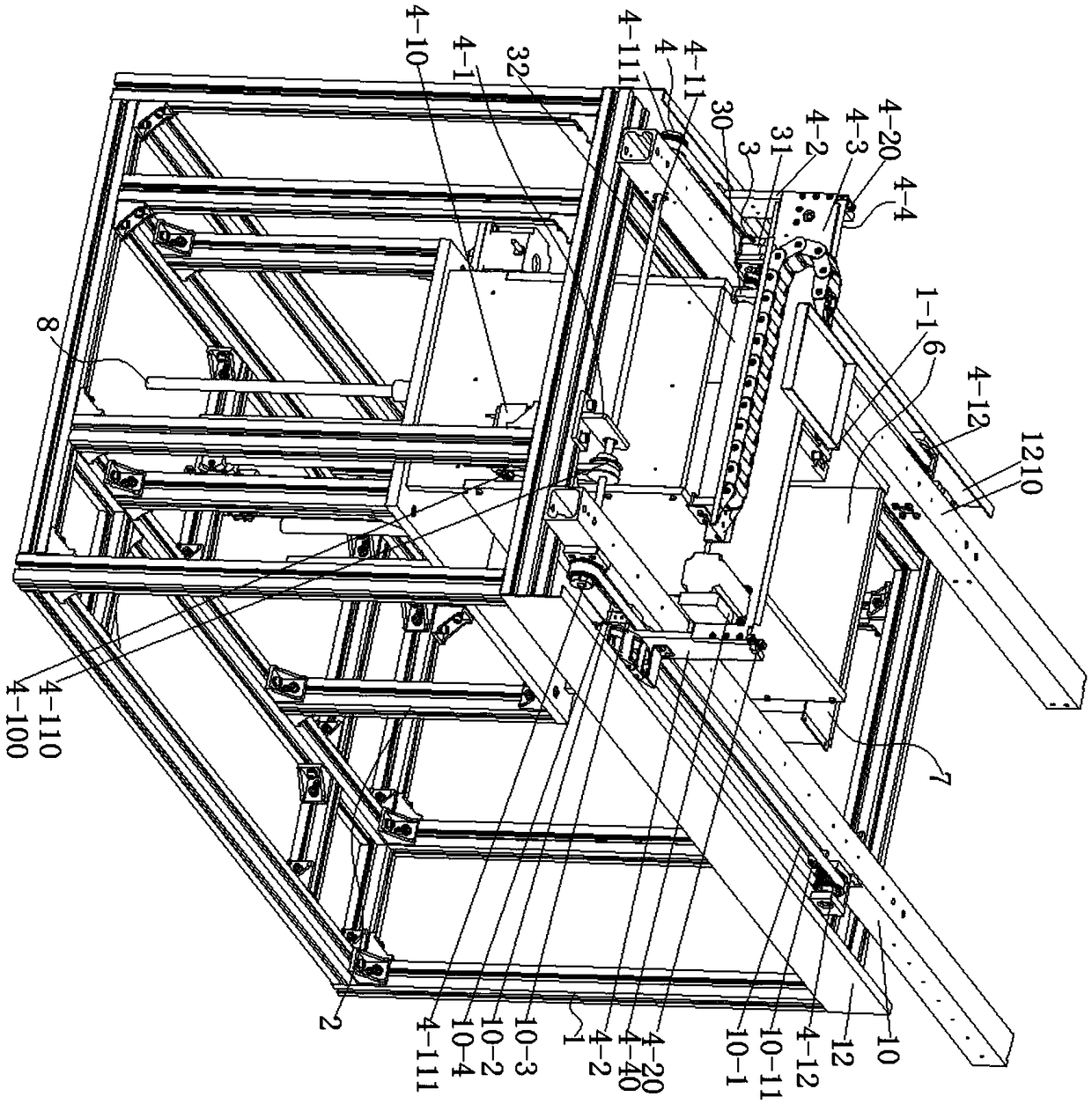

Method used

Image

Examples

Embodiment 1

[0039] The sand mold 3D rapid prototyping equipment using a flatbed printer, the preparation state before work is that the beam 4-3 is located at the leftmost end of the equipment, the sand delivery box 5 is filled with quartz sand with uniform particle size, and the piston in the sand delivery box 5 Plate 1 50 is located at the bottom of the sand delivery box 5, and the piston plate 2 60 in the molding sand box 6 is located at the top of the molding sand box 6. When the equipment is working, the Z-direction mechanism 1 8 works first, that is, the servo motor 4 80 drives synchronously Pulley seven 80-1 rotates in the forward direction, synchronous pulley seven 80-1 drives synchronous pulley eight 81-2 through the synchronous belt and rotates in the flange sleeve one 81-1 with the silk female sleeve one 81-1, and the silk female sleeve one 81-1 drives screw rod 1 81-10 to move upwards, and then under the guiding action of guide rod 1 82, screw rod 1 81-10 pushes piston plate 1 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com