Four-laser four-galvanometer selective laser melting additive and subtractive forming device and method

A technology of selective melting and forming device, which is applied in the field of additive manufacturing, can solve the problems of poor precision of laser selective melting and forming, and achieve the effect of shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

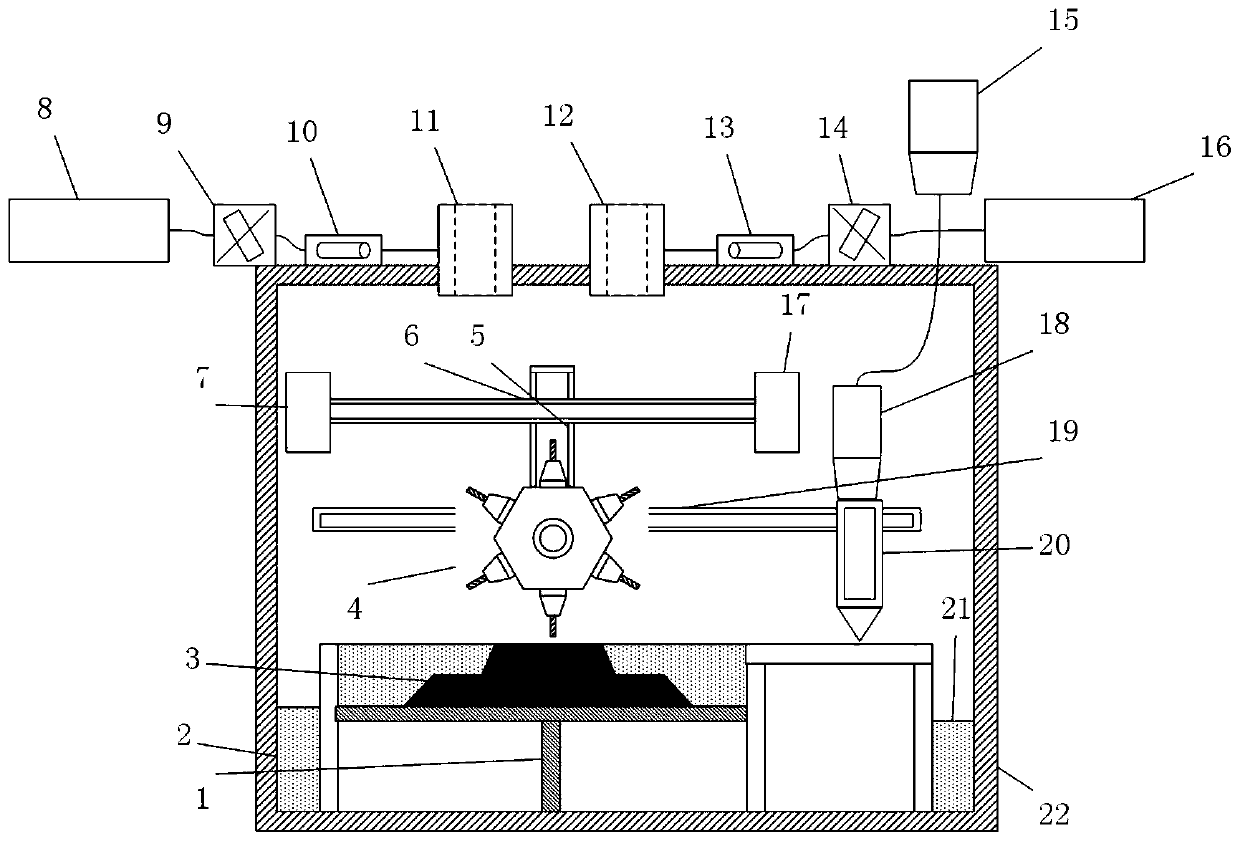

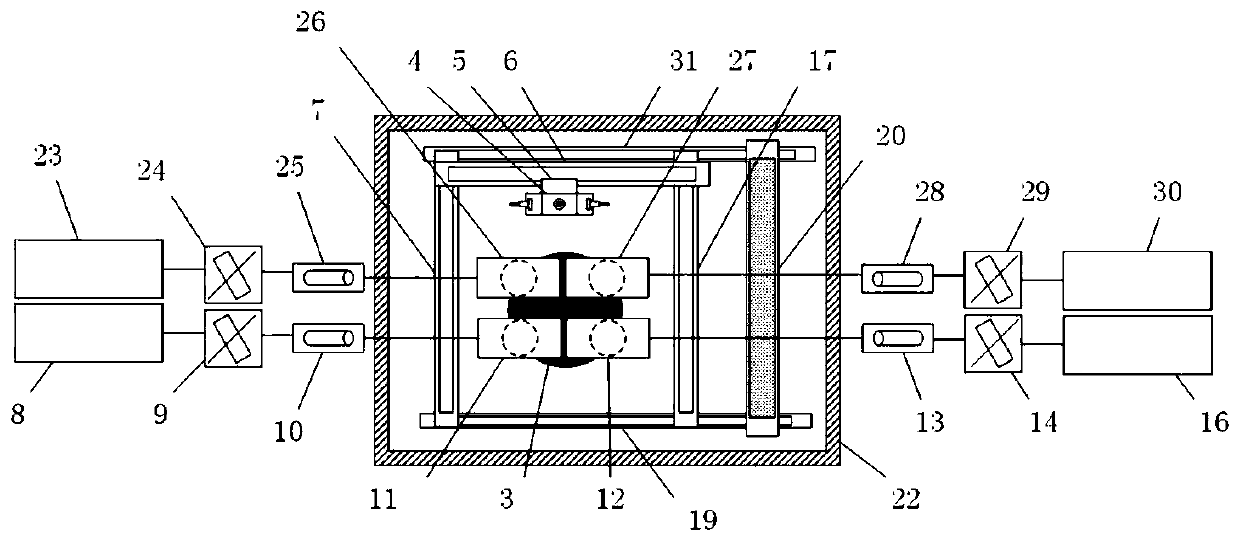

[0026] Such as figure 1 and figure 2 As shown, a four-laser four-galvanometer selective-area melting increase and decrease material forming device mainly includes a sealed molding chamber, which is the processing chamber of the equipment. There are industrial computers, powder feeding and spreading equipment, and powder crumb recovery equipment. , Circulation purification equipment and milling processing equipment.

[0027] The sealing molding chamber 22 is provided with a processing molding platform, and the molding platform is fixed on the bottom of the sealing molding chamber through the molding cylinder 1. Its molding processing size is 250mm×250mm×300mm, and the up and down movement of the molding cylinder is controlled by a precision motor, thereby realizing Layer-by-layer precision machining of samples.

[0028] The present invention also includes galvanometer optical path equipment, the galvanometer optical path equipment includes four dynamic focusing scanning galv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com