Preparation method of wind turbine blade

A wind power blade and integrated technology, applied in the field of wind power blade preparation, can solve problems affecting the reliability of the blade structure, difficult to achieve bonding thickness, and bonding thickness exceeding the standard, so as to achieve rapid prototyping, reduce bonding difficulty, and avoid The effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

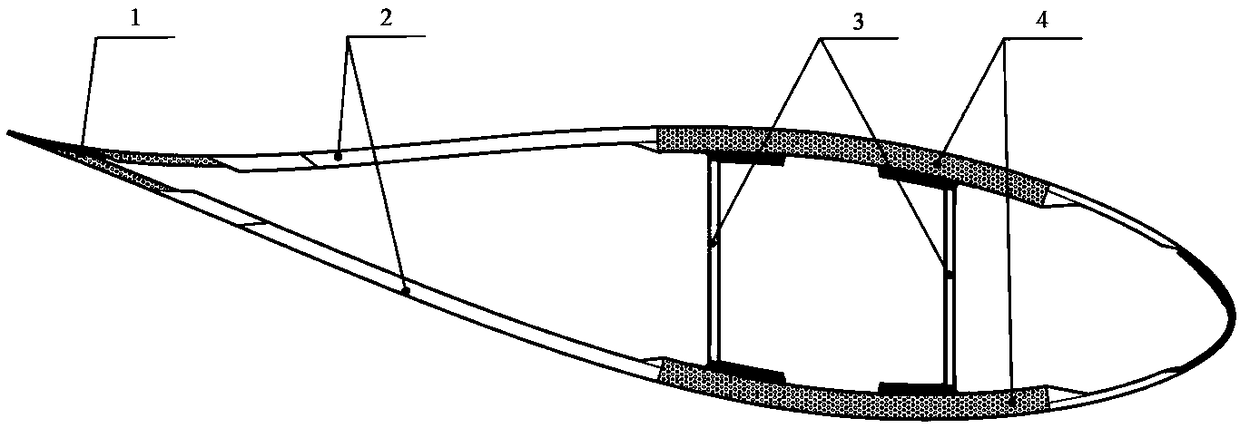

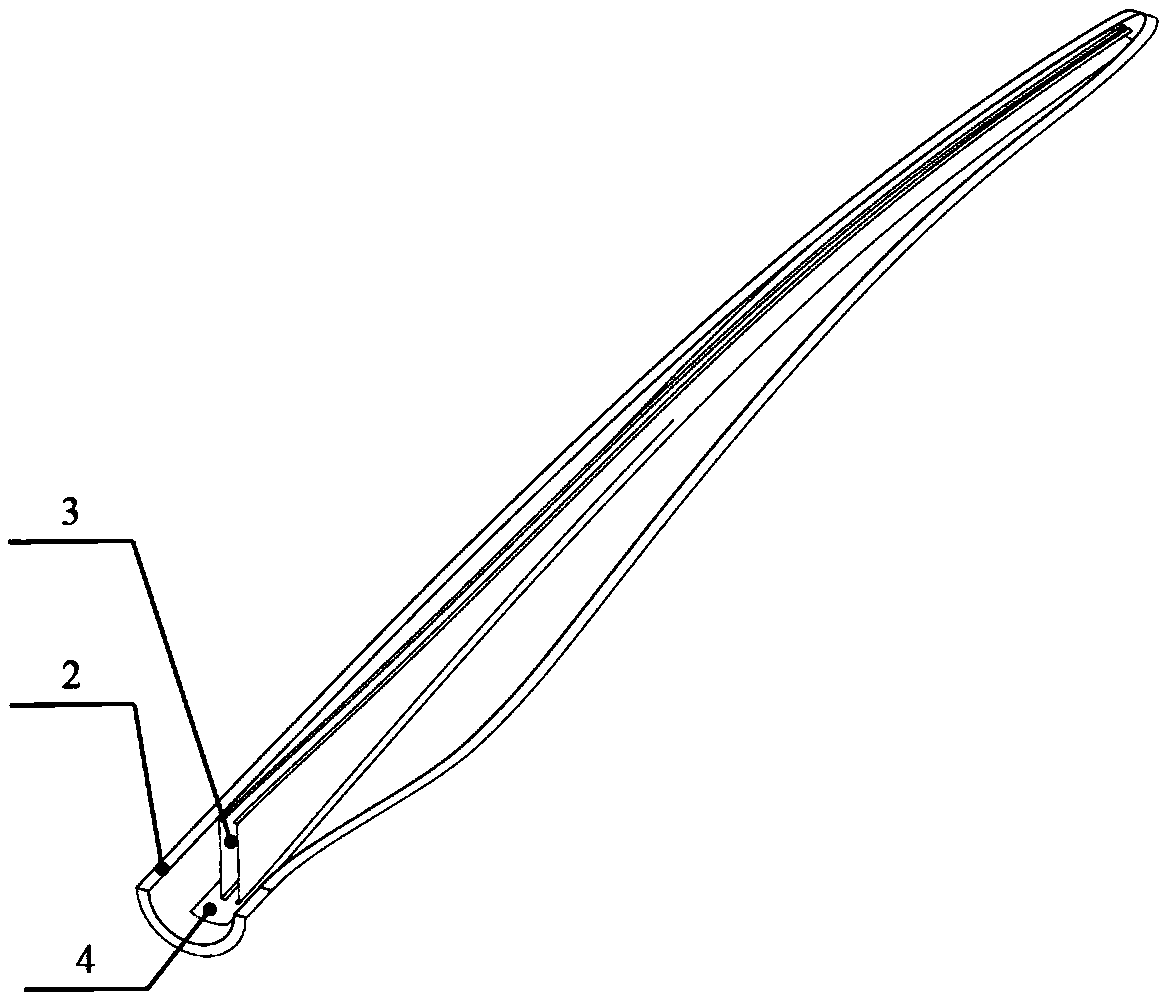

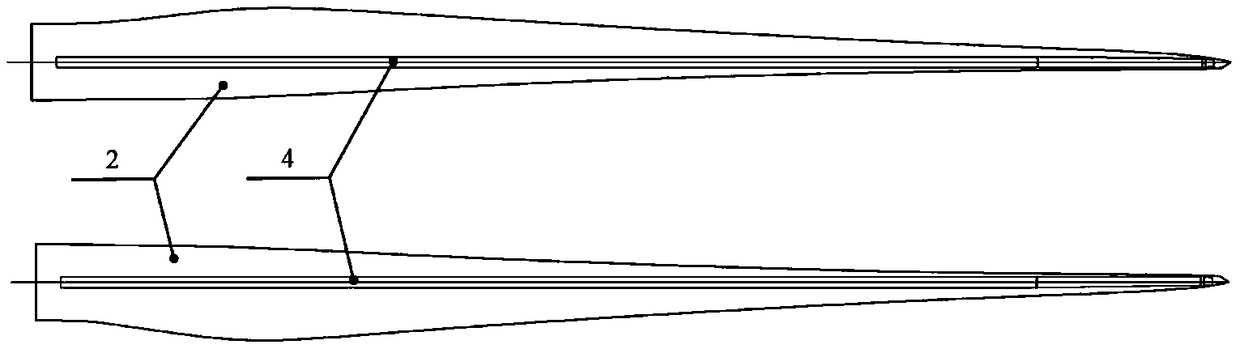

Image

Examples

Embodiment 1

[0039] 1) The suction side girder, the pressure side girder, the front edge web, the rear edge web and the prefabricated rear edge are prepared respectively by the vacuum injection molding process, and the glass fiber cloth and the suction side girder are sequentially laid in the suction side shell mold , sandwich core and lower glass fiber cloth, lay release cloth on the upper surface of the shell layer after the shell layer is completed, lay the upper surface guide net and the upper surface air suction bag on the upper surface of the release cloth, and then place the Lay a sealed vacuum bag film on the entire shell mold, and set the injection port and vacuum suction port in the molding cavity, vacuumize to maintain a vacuum degree ≤ -0.098Mpa; vacuum infuse the resin until the resin system is completely cured, after demoulding Obtain an integral molding of the suction side shell and the suction side girder; prepare the integral molding of the pressure side shell and the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com