Patents

Literature

40results about How to "Reduce the difficulty of bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro light-emitting-diode display panel and manufacturing method thereof

ActiveUS20180342691A1Increase contactReduce difficultySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringResin adhesive

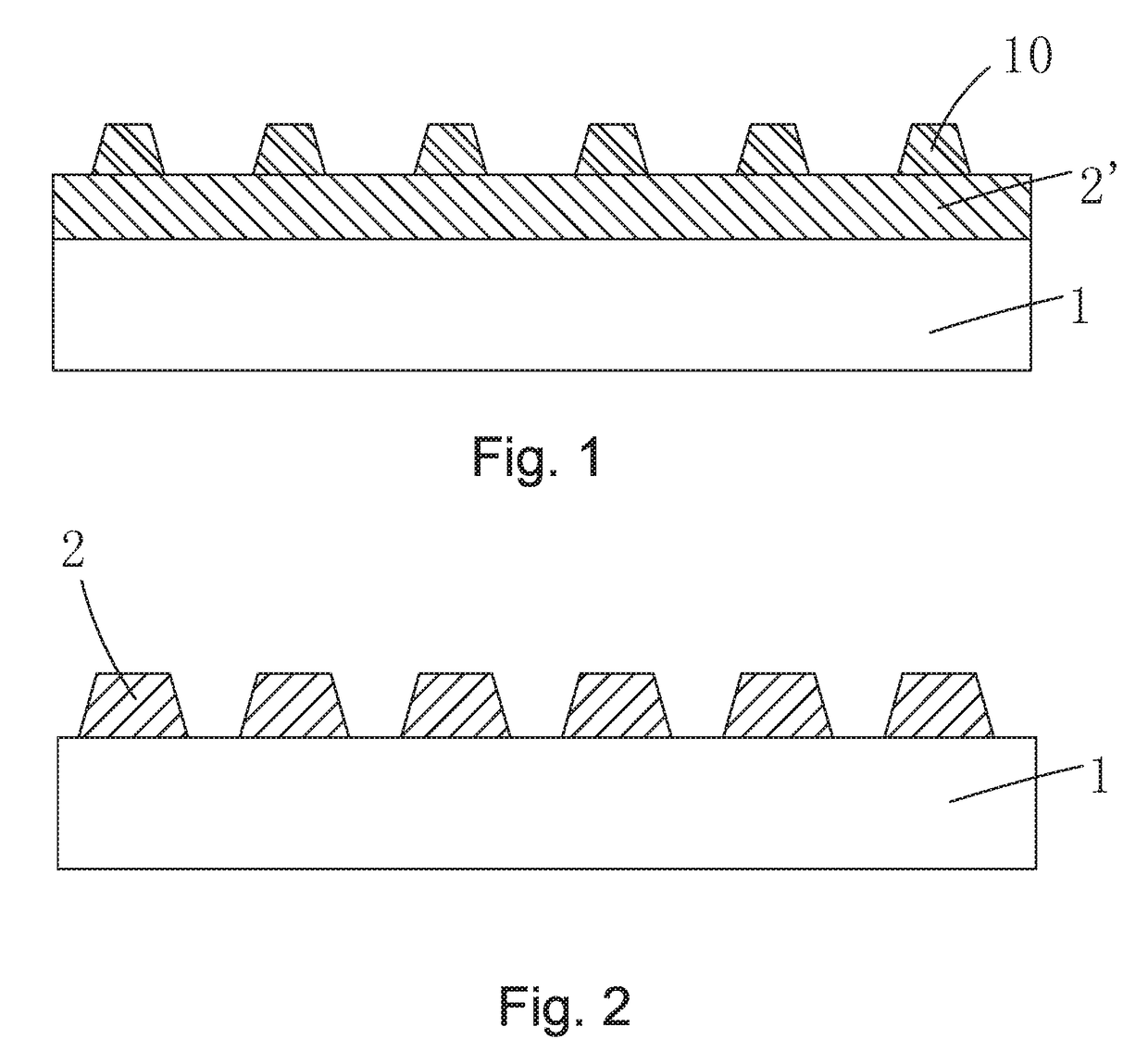

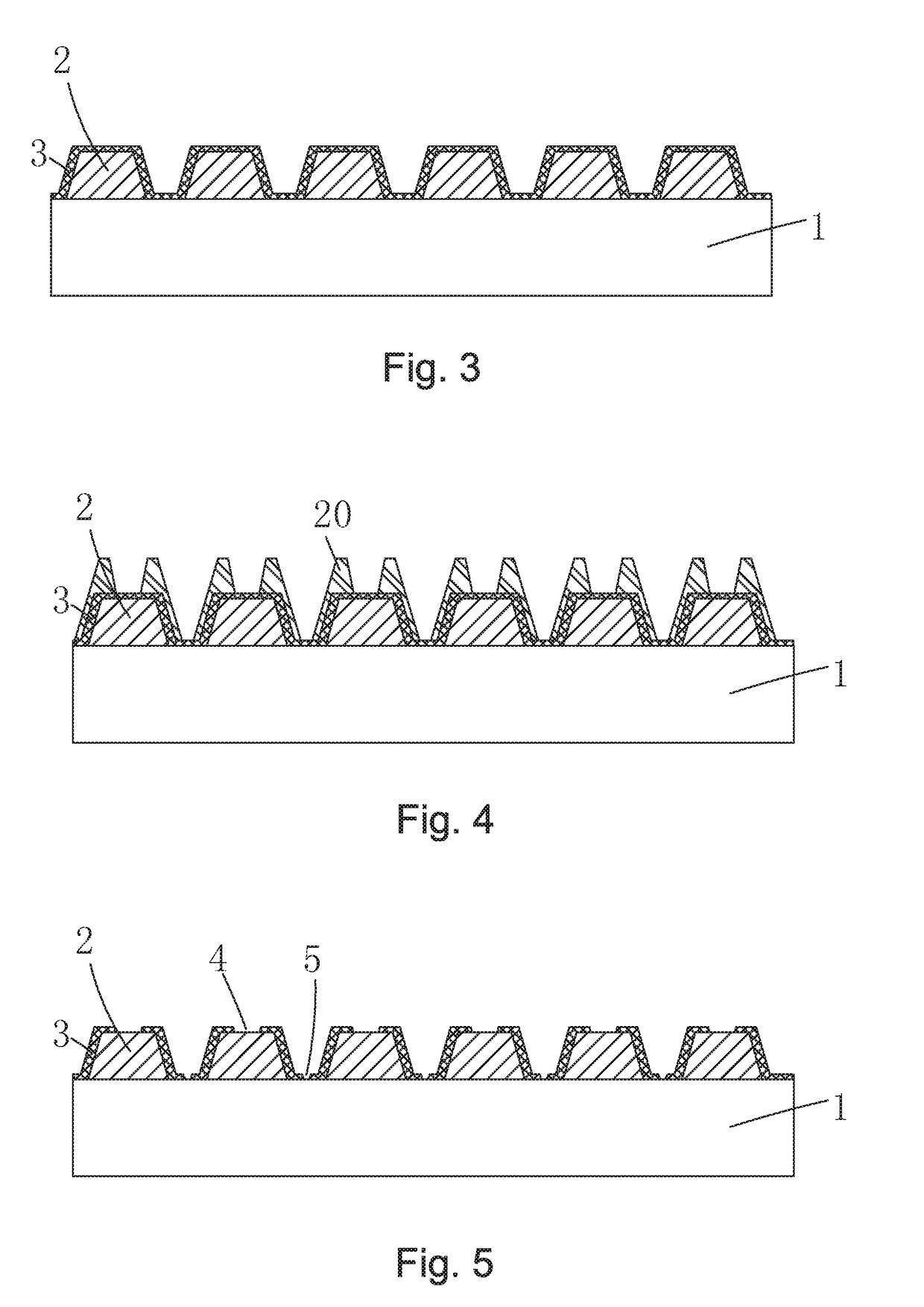

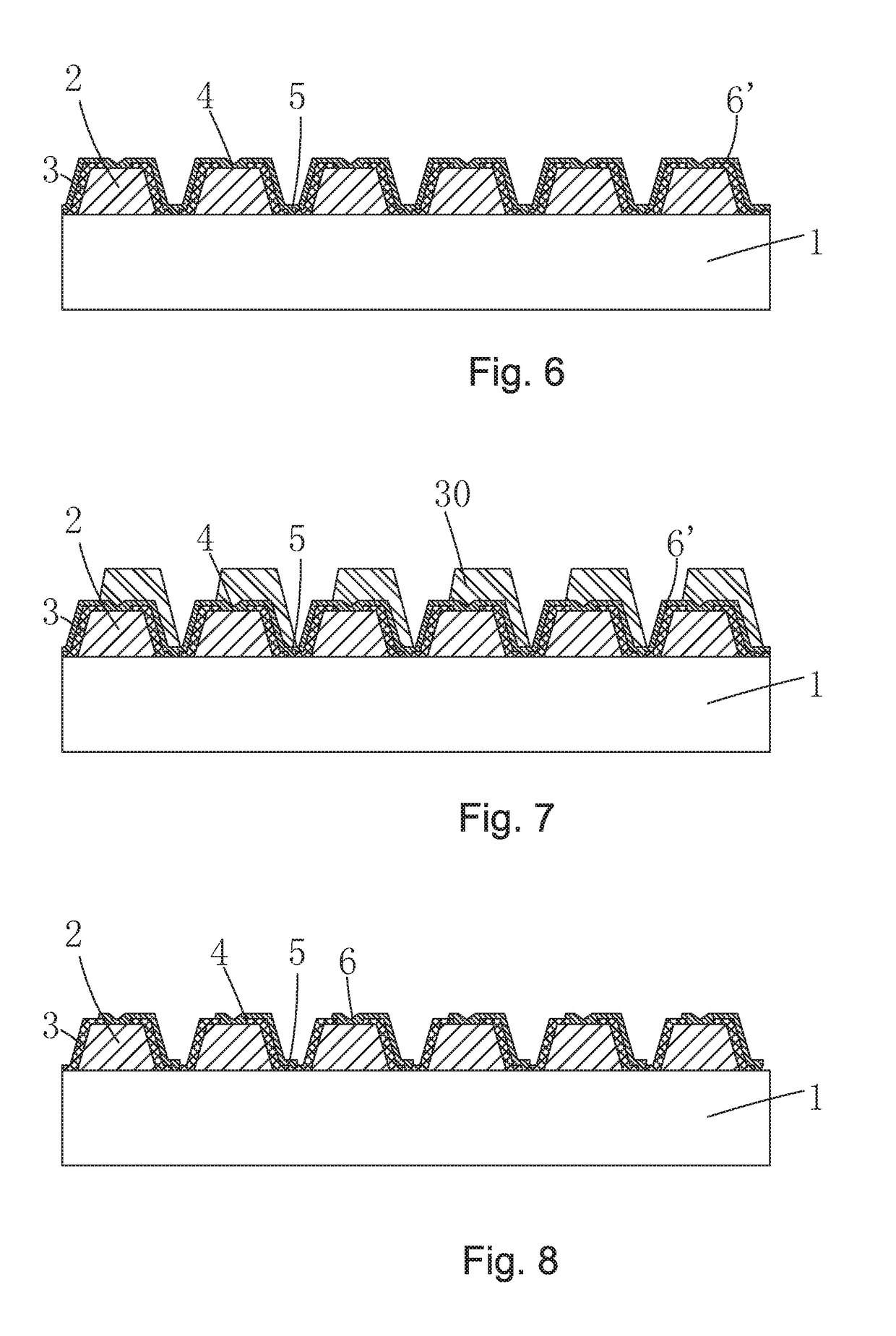

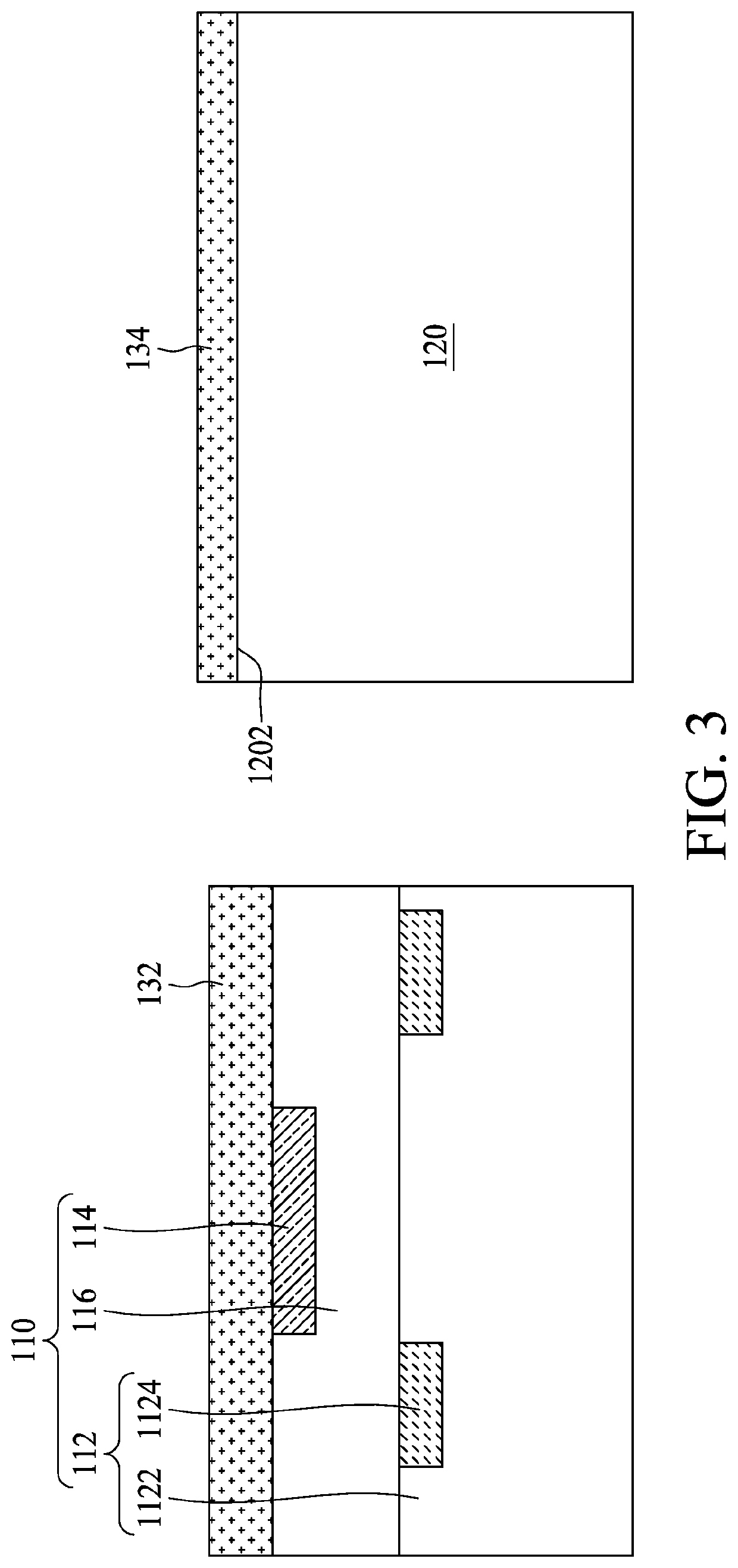

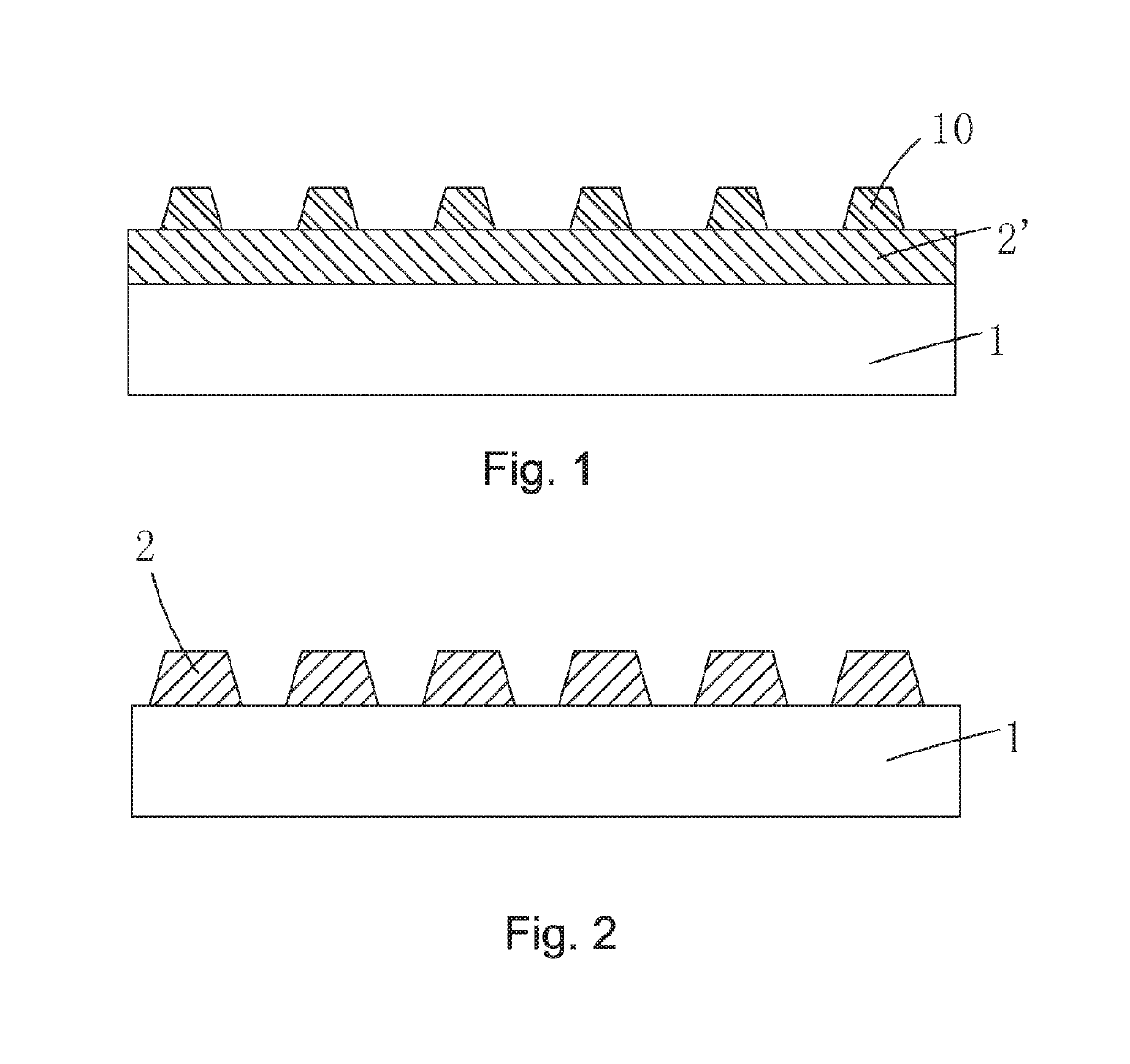

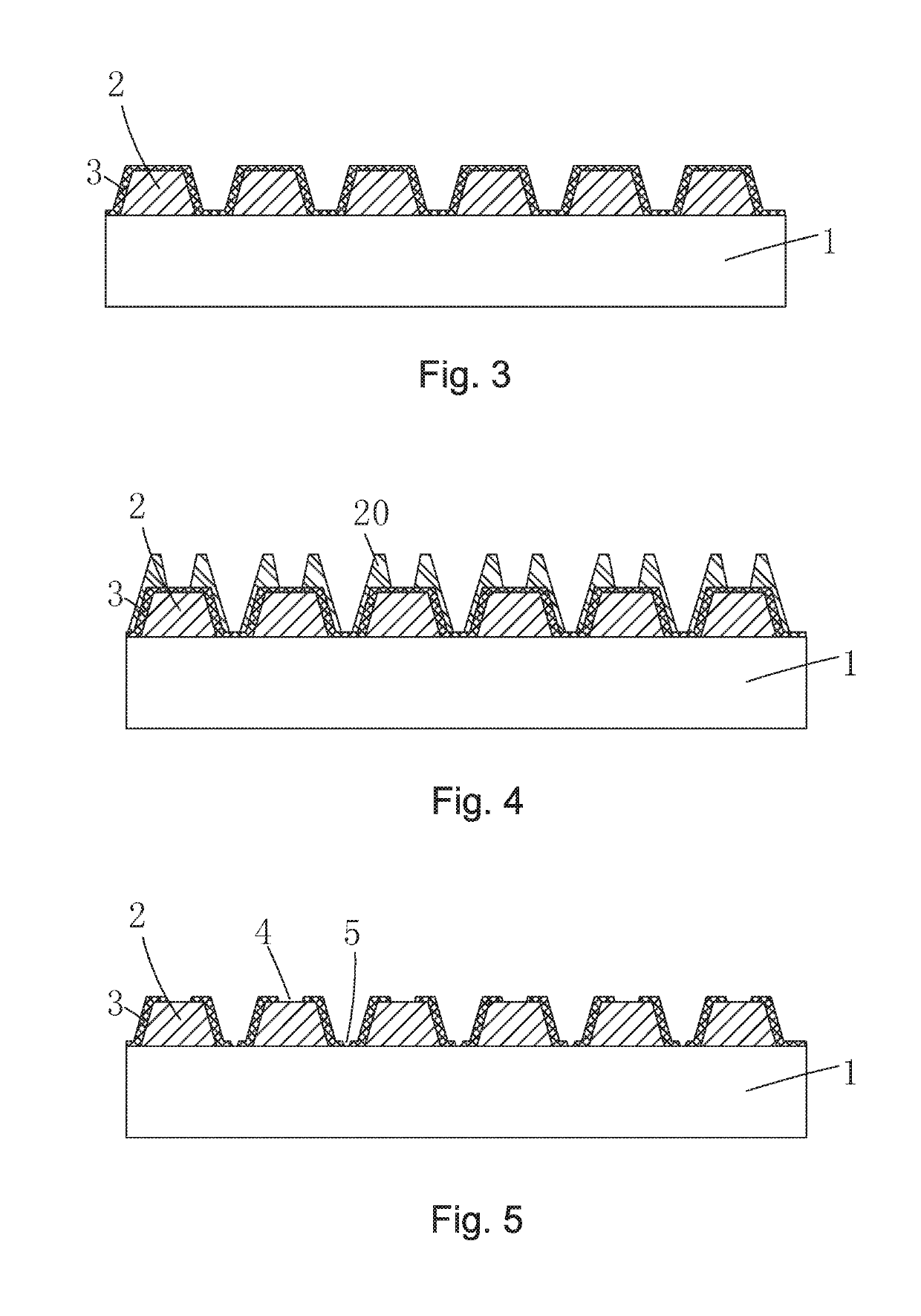

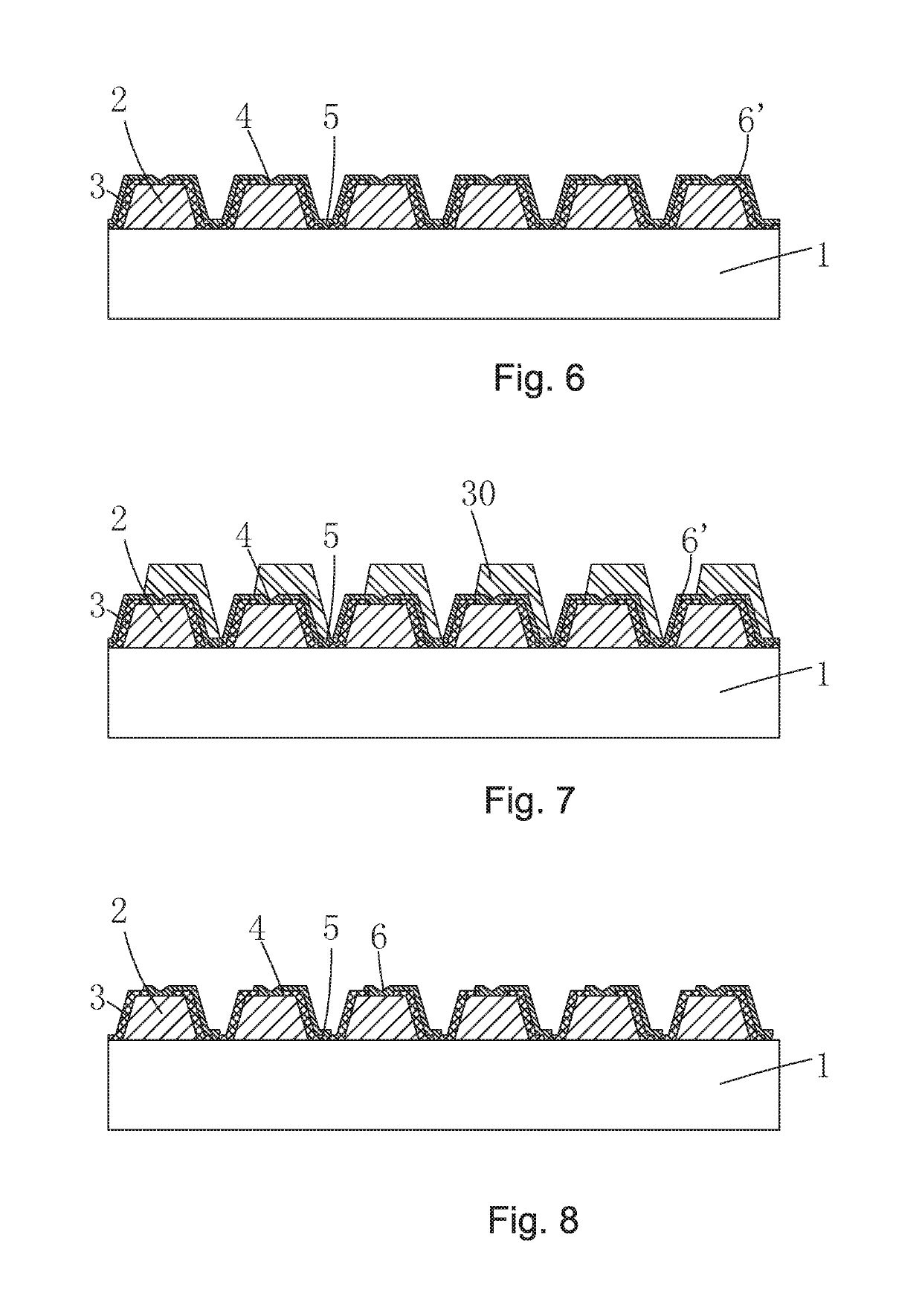

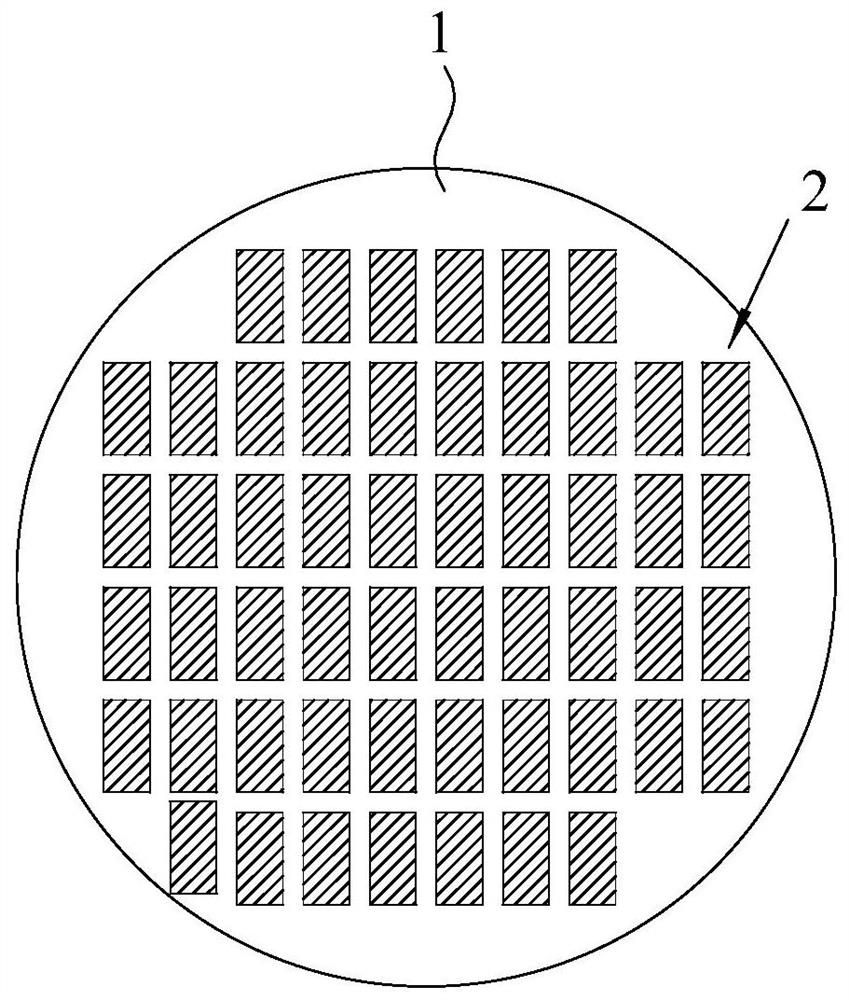

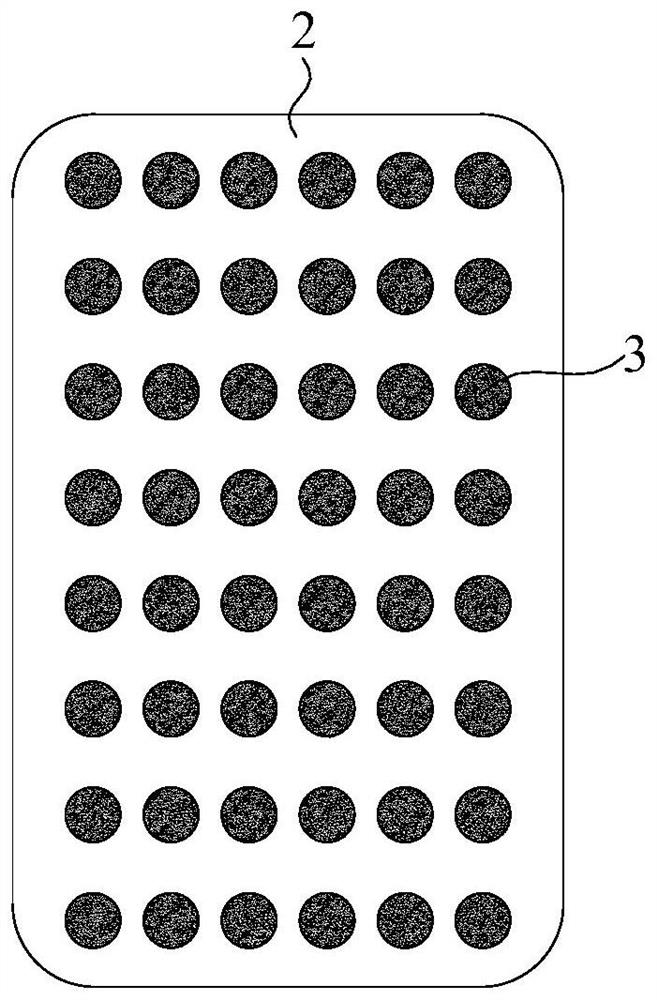

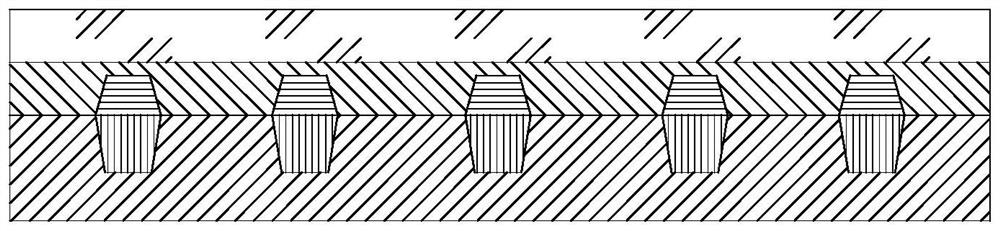

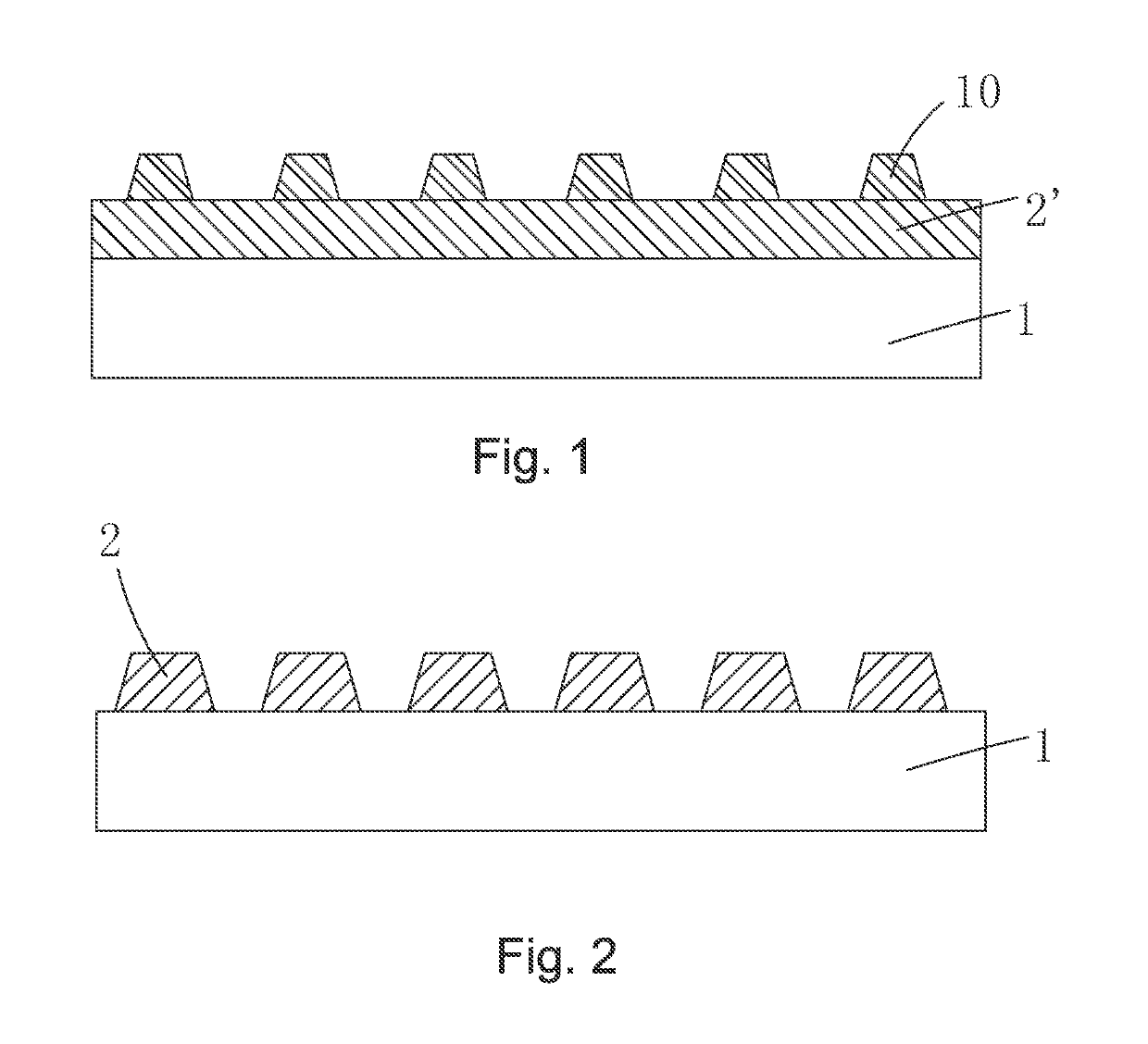

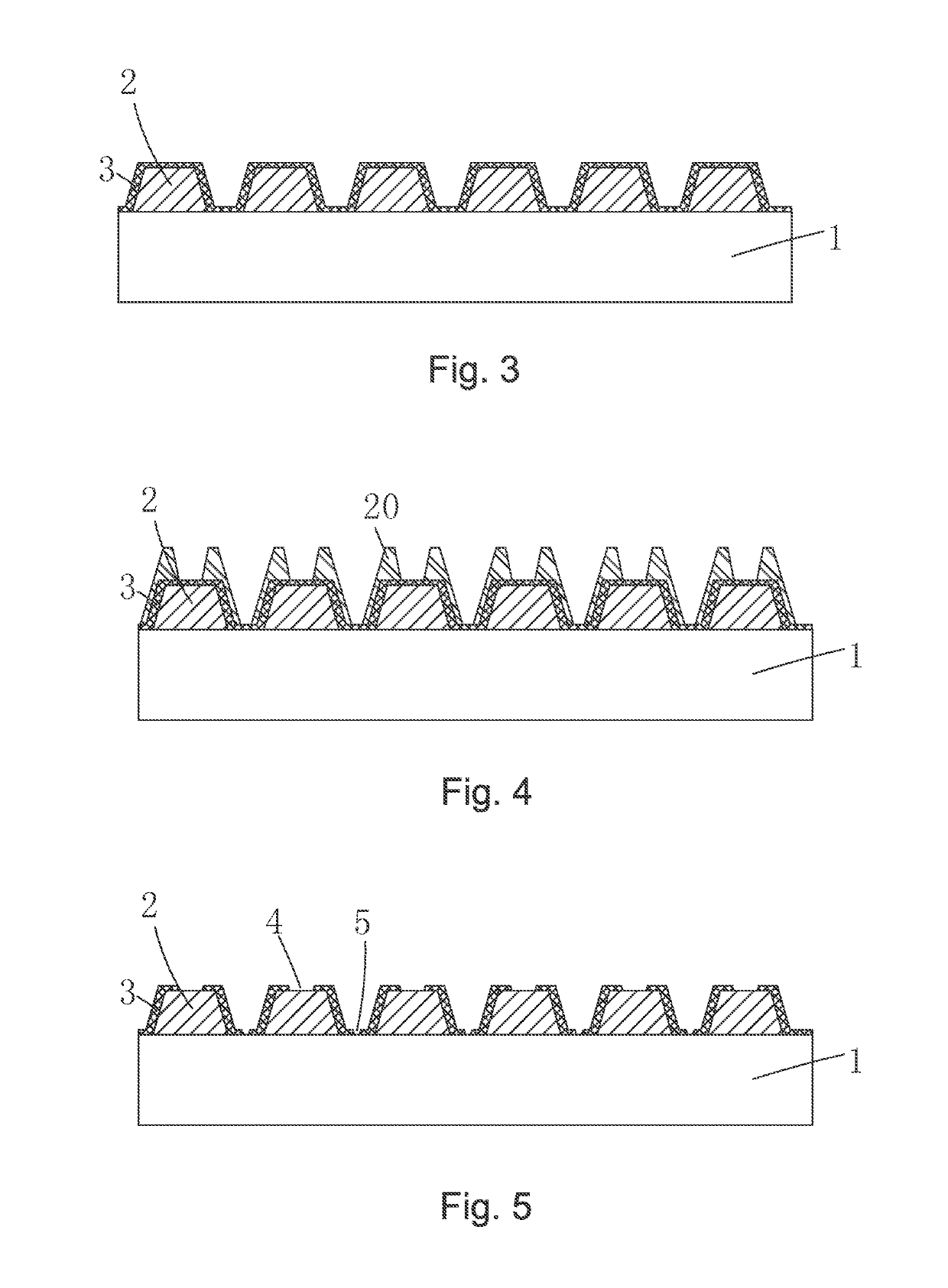

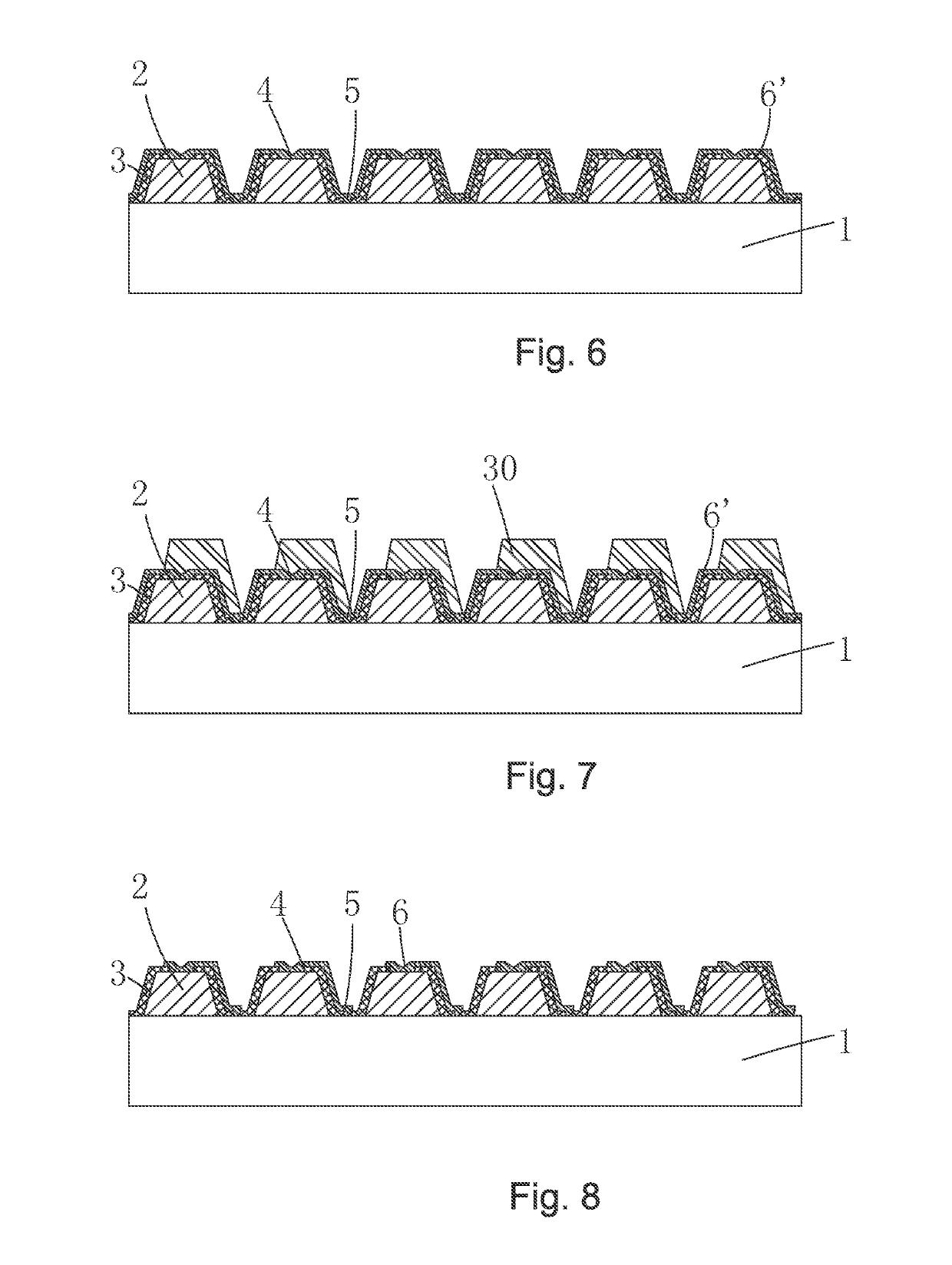

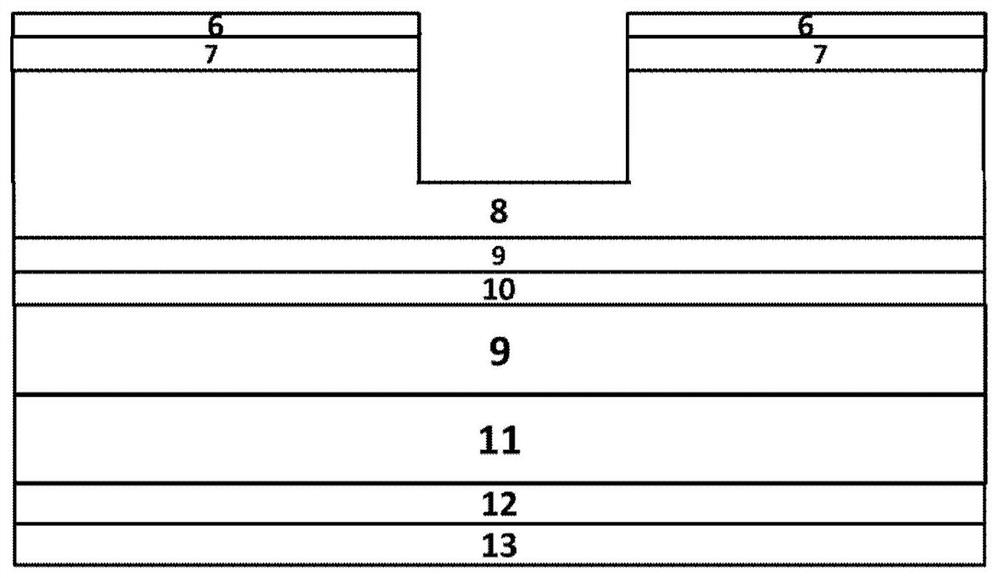

The present invention provides a micro light-emitting-diode display panel and a manufacturing method thereof. The micro light-emitting-diode display panel which presses and fixes the micro light-emitting-diodes into a resin adhesive layer by filling the resin adhesive layer in the pixel groove. Meanwhile, the electrode at the bottom of the micro light-emitting-diode is guided to the top of the micro light-emitting-diode by the connection electrode, making the two electrodes of the micro light-emitting-diode are at the top, to facilitate the connection between the electrodes of the micro light-emitting-diode and the electrode points, which can reduce the difficulty of the electrode bonding of the micro light-emitting-diode, and improve the reliability of the electrode bonding of the micro light-emitting-diode.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

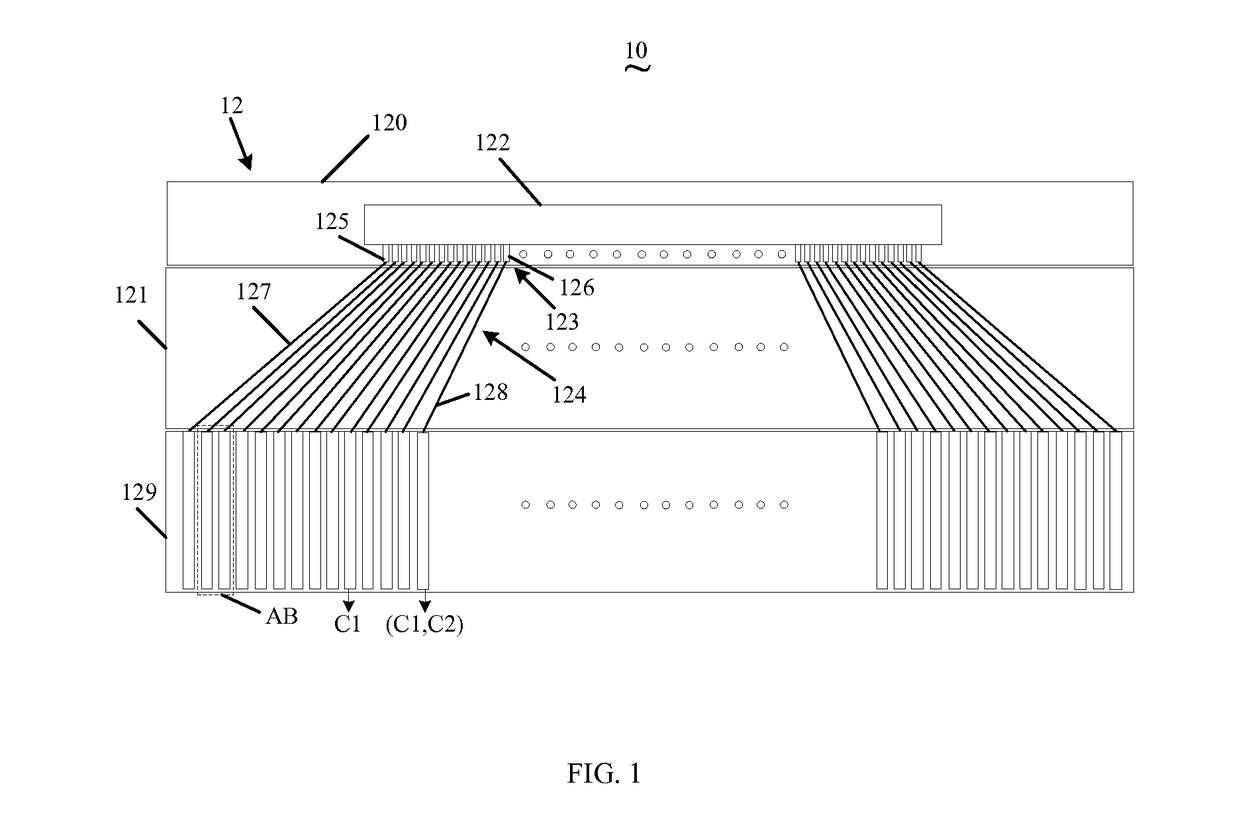

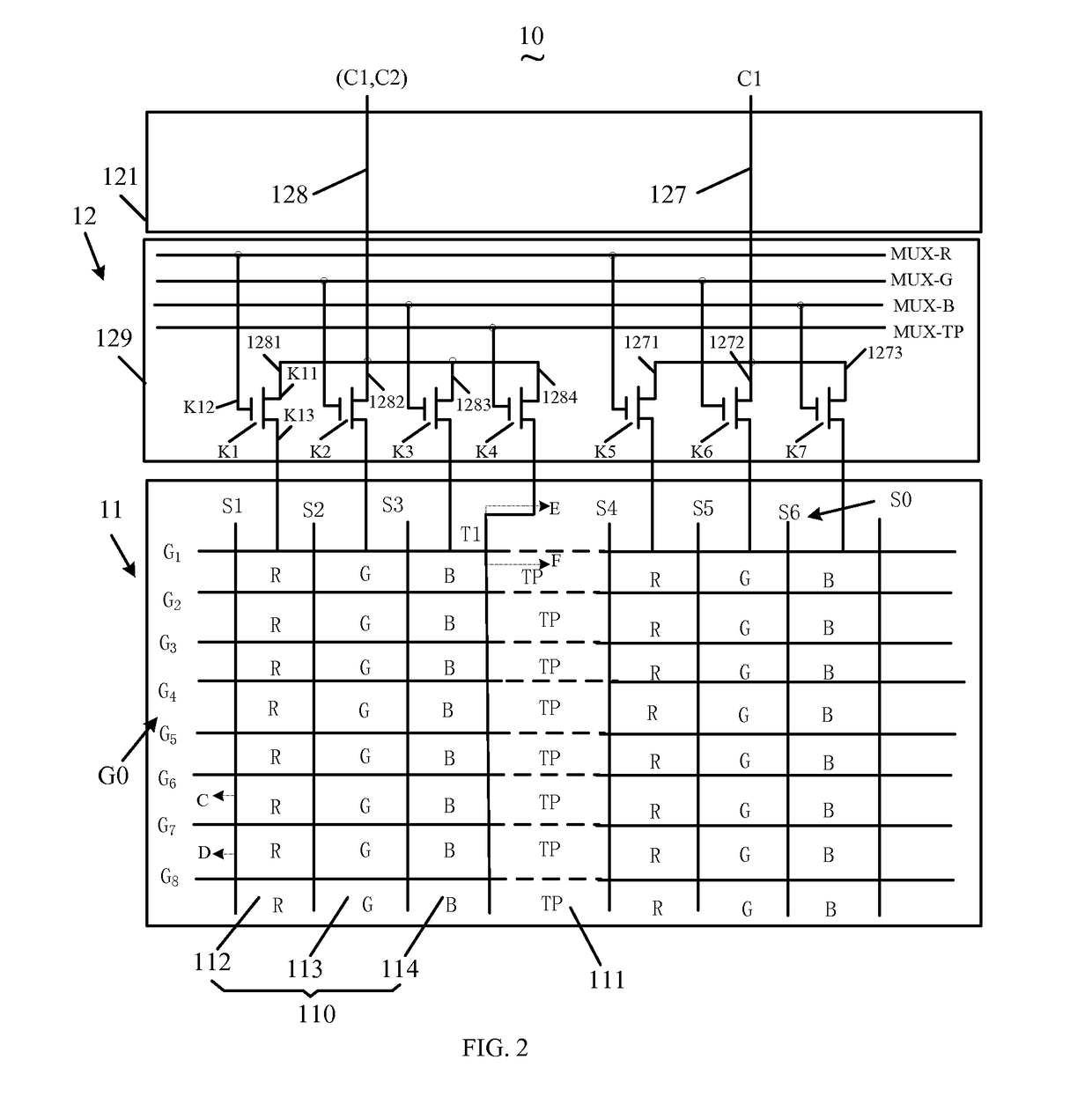

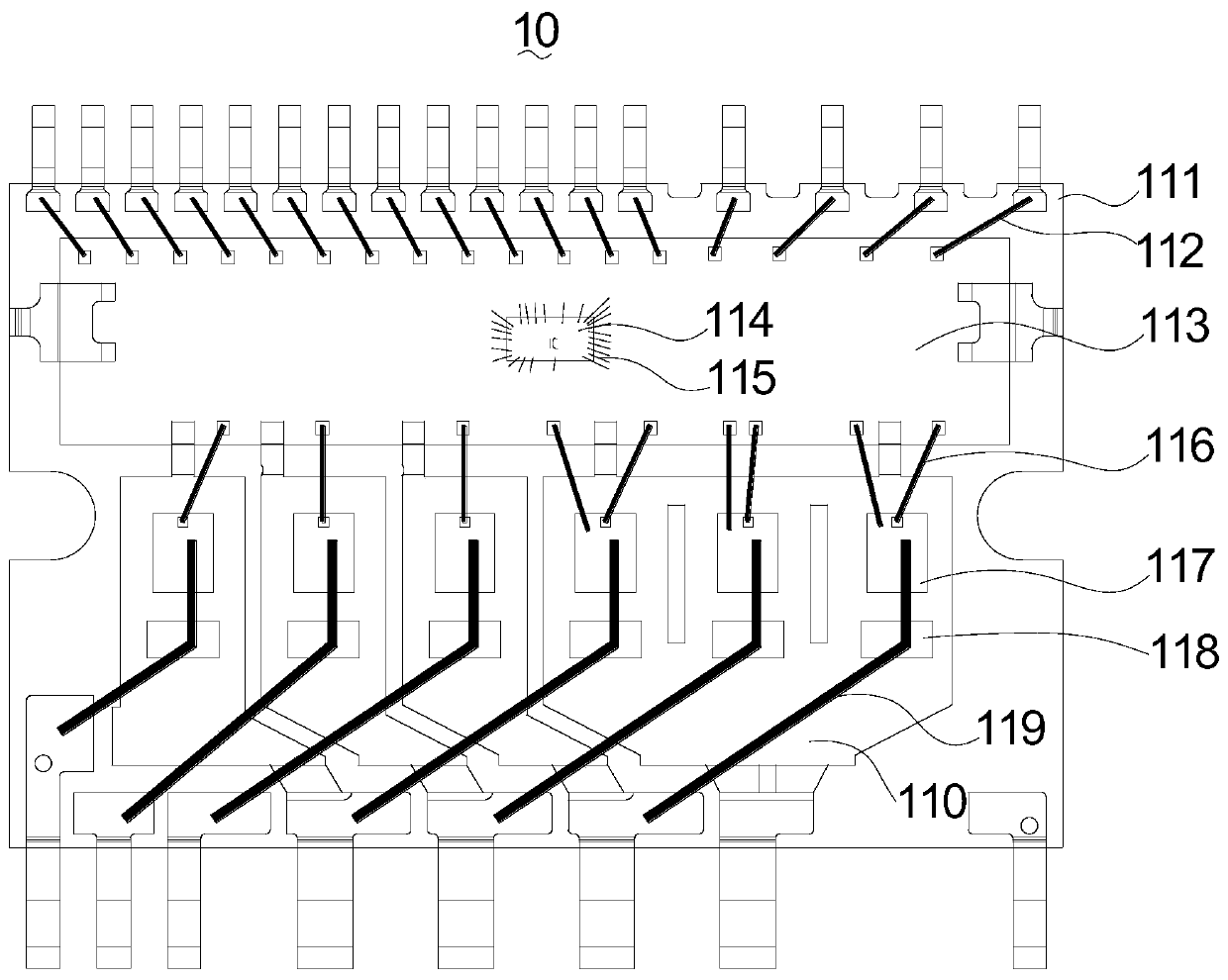

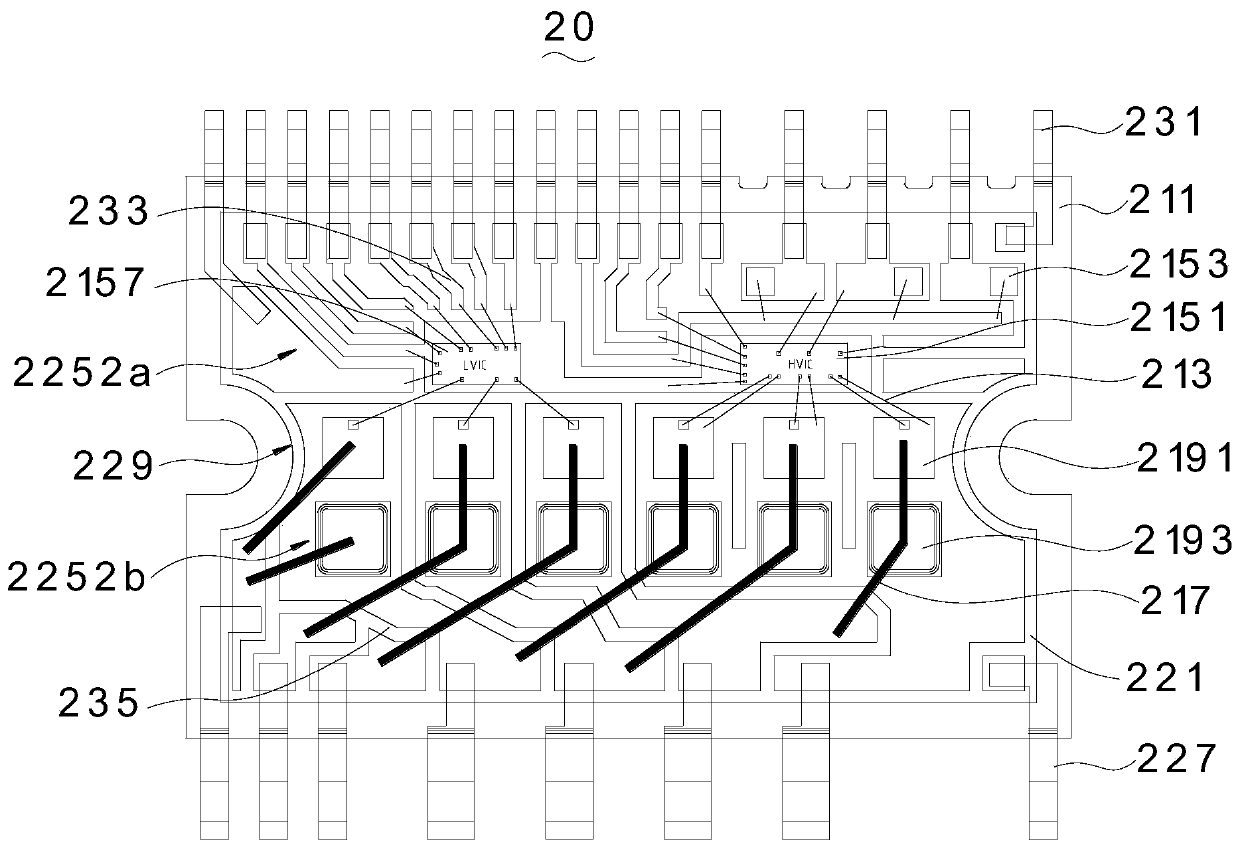

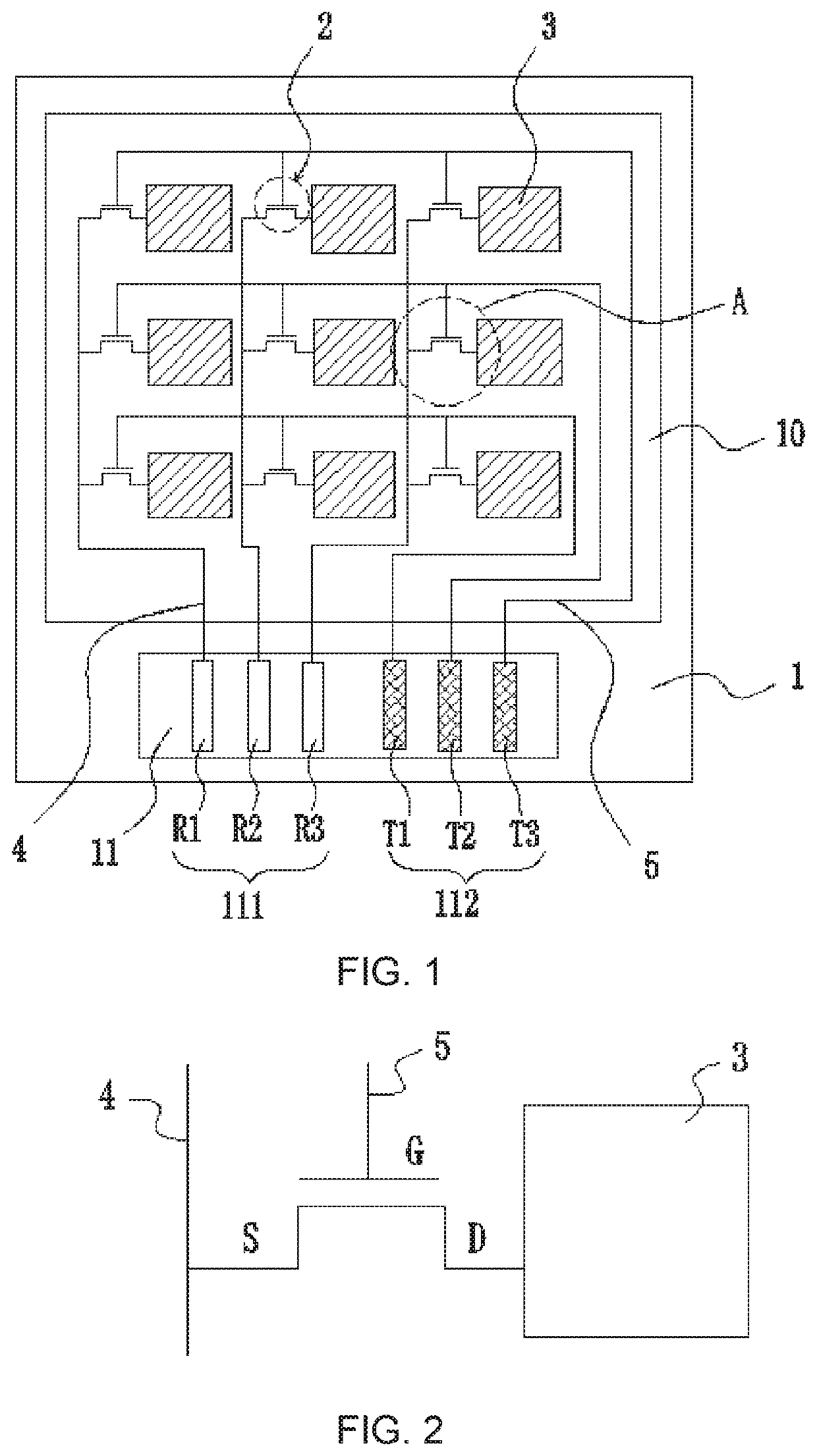

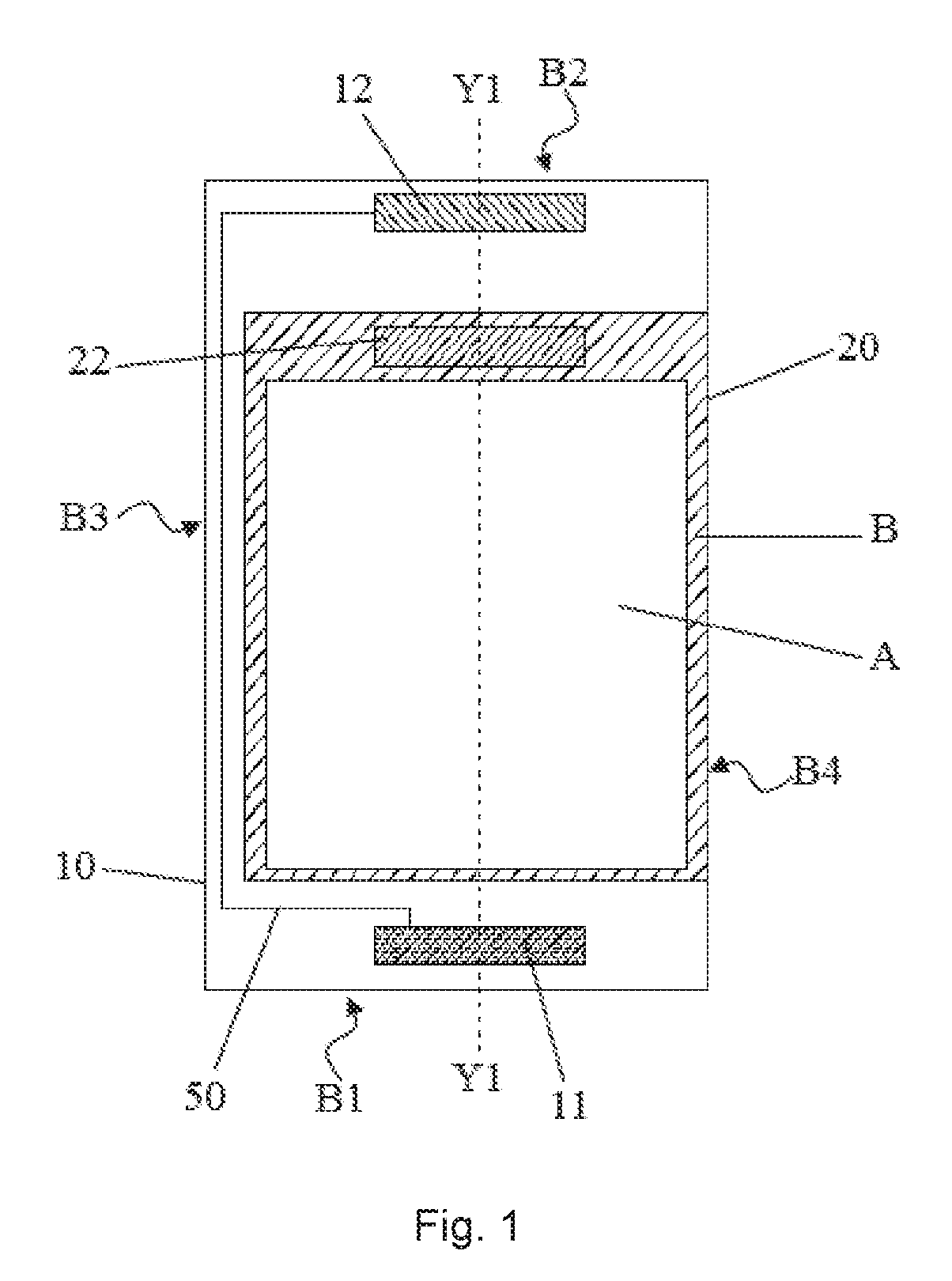

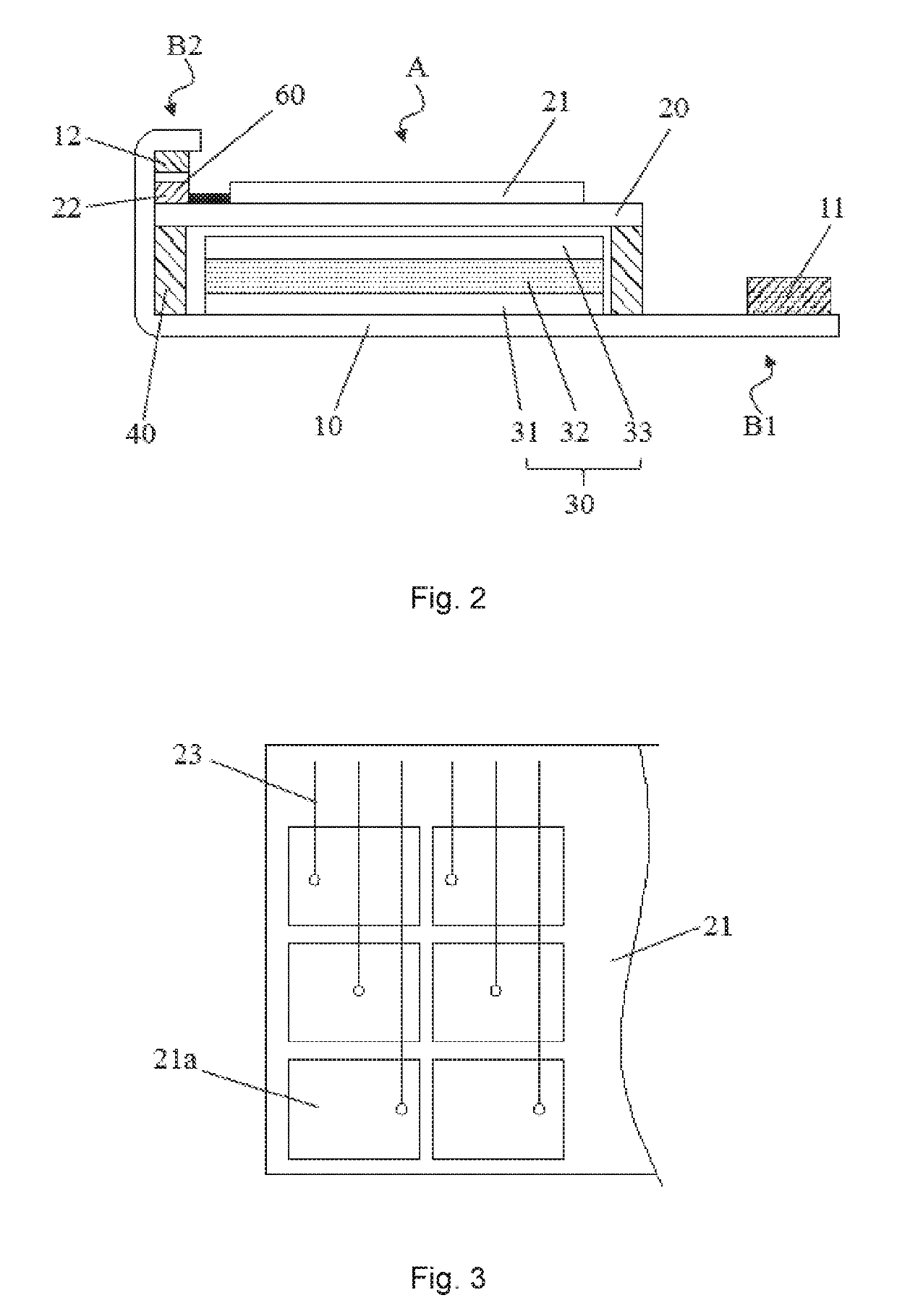

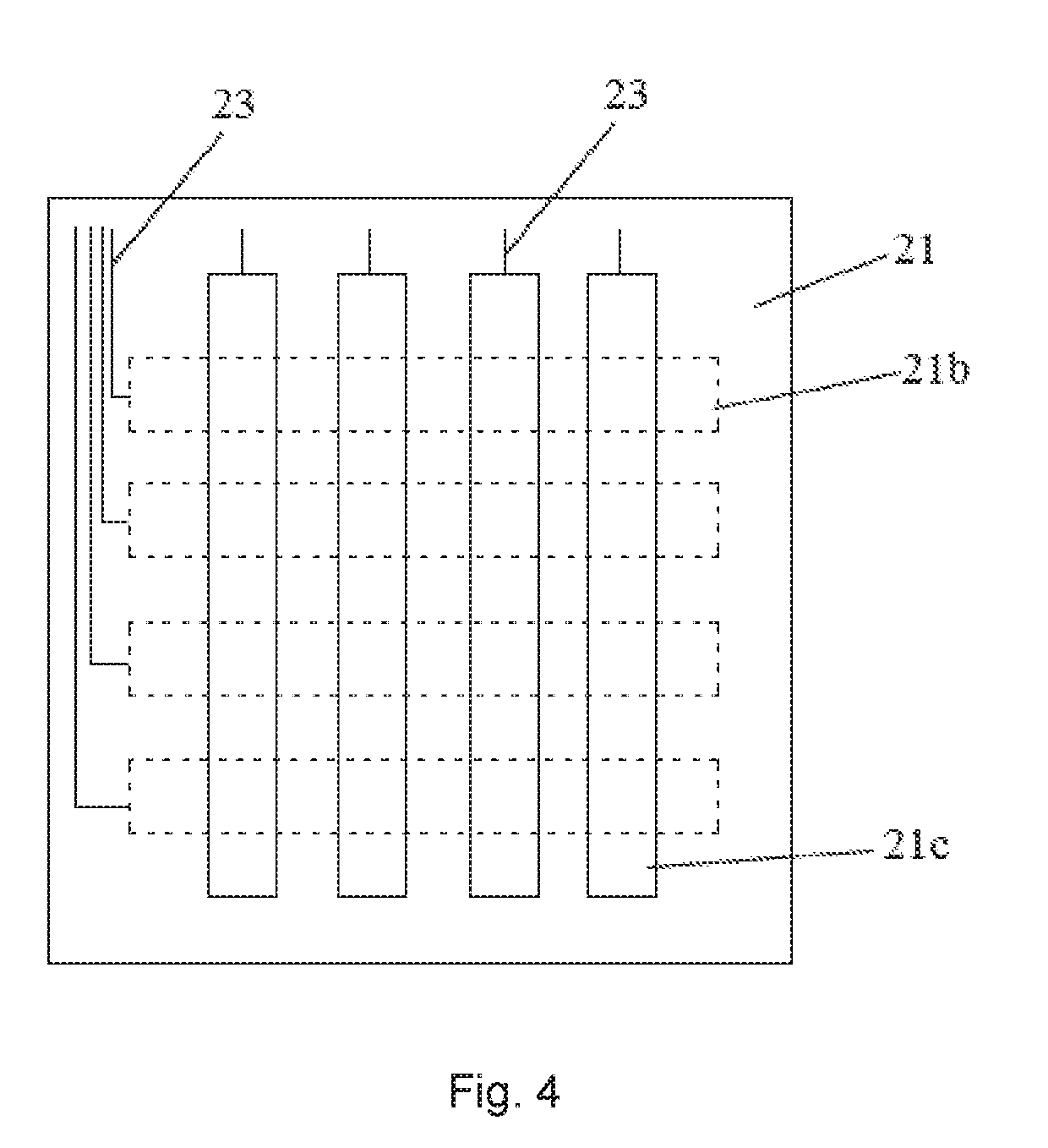

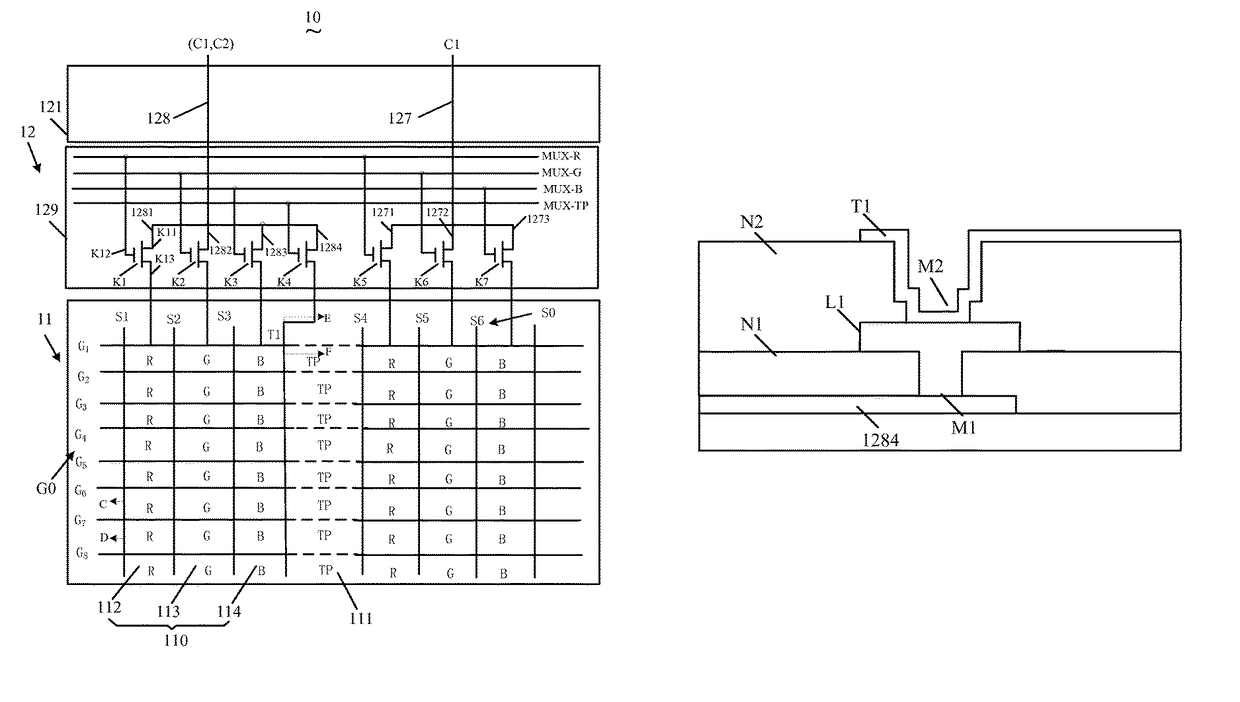

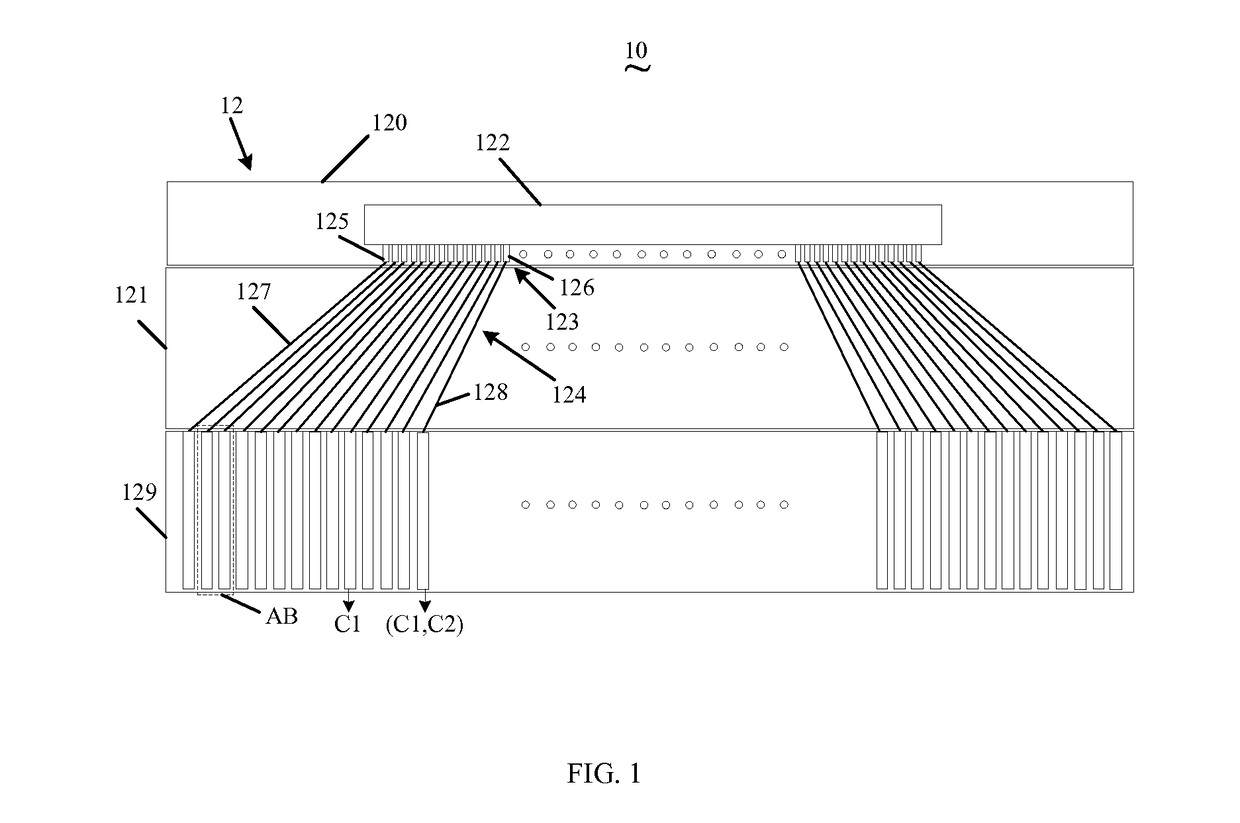

Touch panels and the driving method thereof

ActiveUS20170139534A1Reduce difficultyImprove performanceStatic indicating devicesNon-linear opticsCapacitanceManufacturing technology

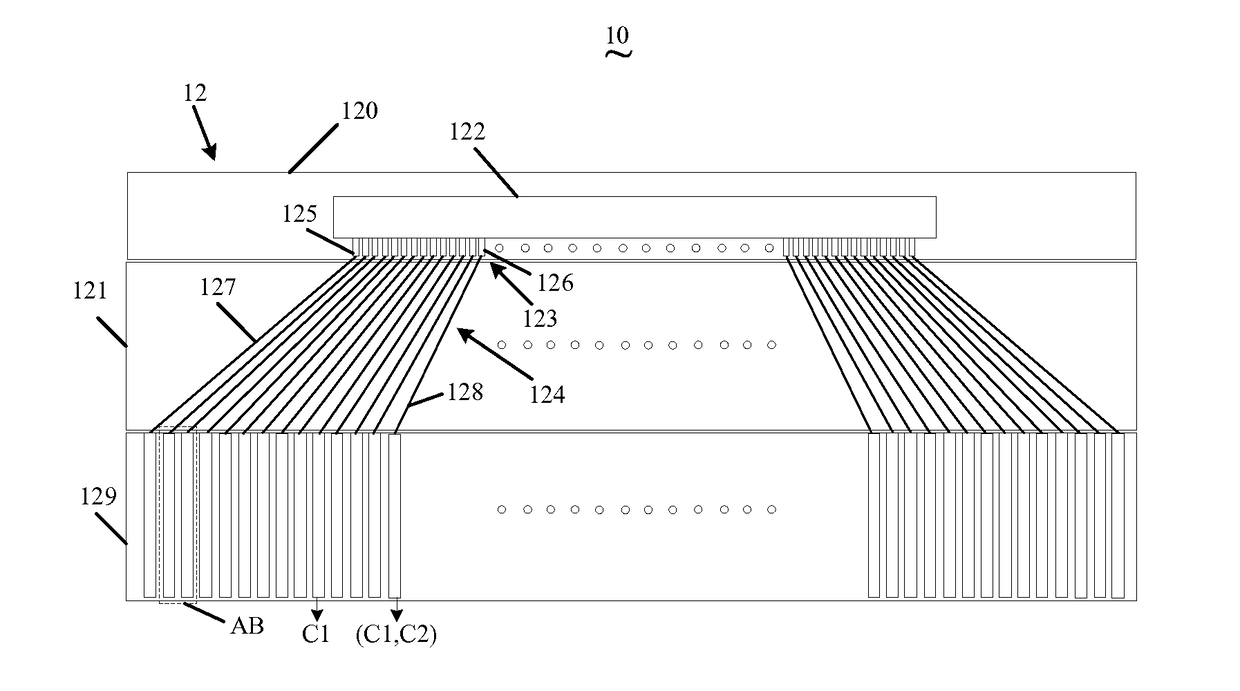

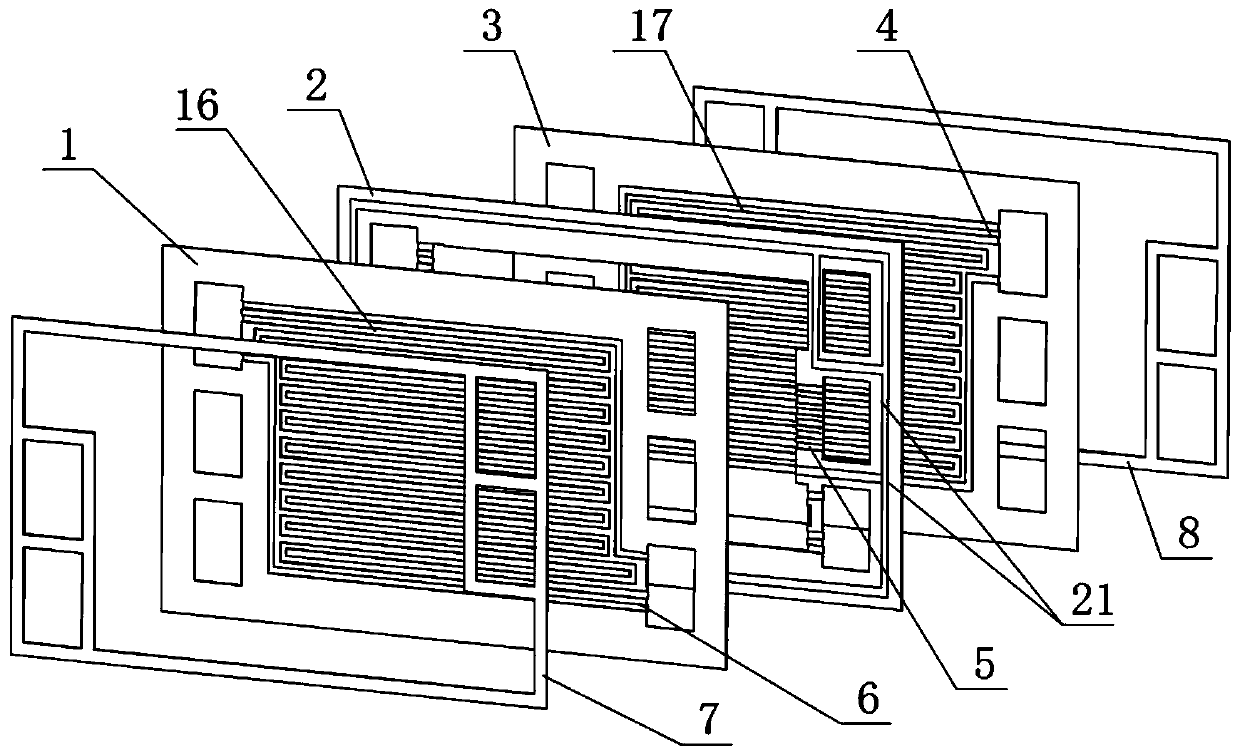

A touch panel and a driving method are described in the present disclosure. A driving chip is arranged within a chip area of a non-display area. The driving chip includes a plurality of pins. At least a portion of the pins outputs first driving signals for controlling the pixel electrodes, and outputs second driving signals for controlling the touch sensor. A plurality of wirings corresponding to the pins is arranged within the fan area, and the wirings transmit the first driving signals and the second driving signals outputted by the pins. In view of the above, the difficulties of the bonding manufacturing process are reduced. At the same time, the coupling capacitance between the wirings is reduced, and thus the display performance and the touch sensibility of the touch panel 10 are enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

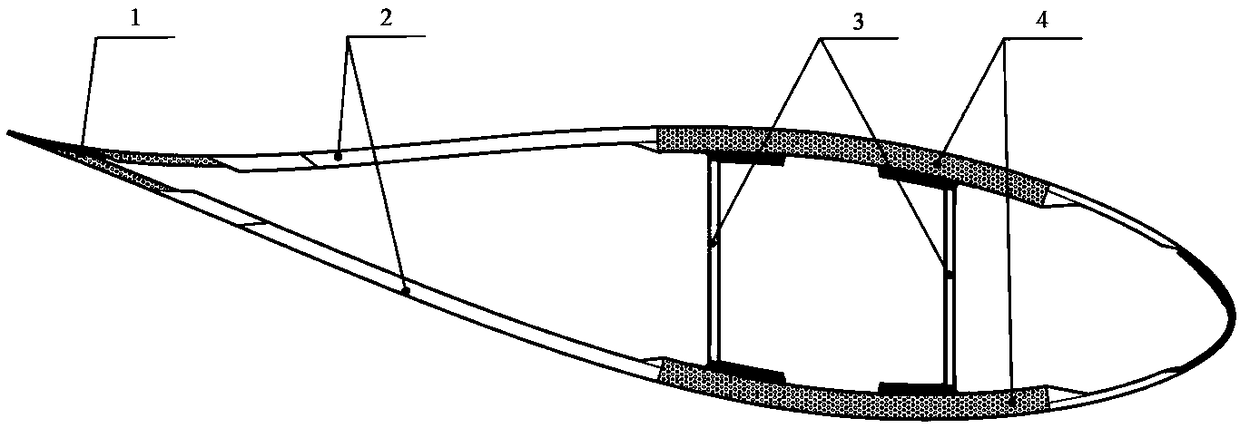

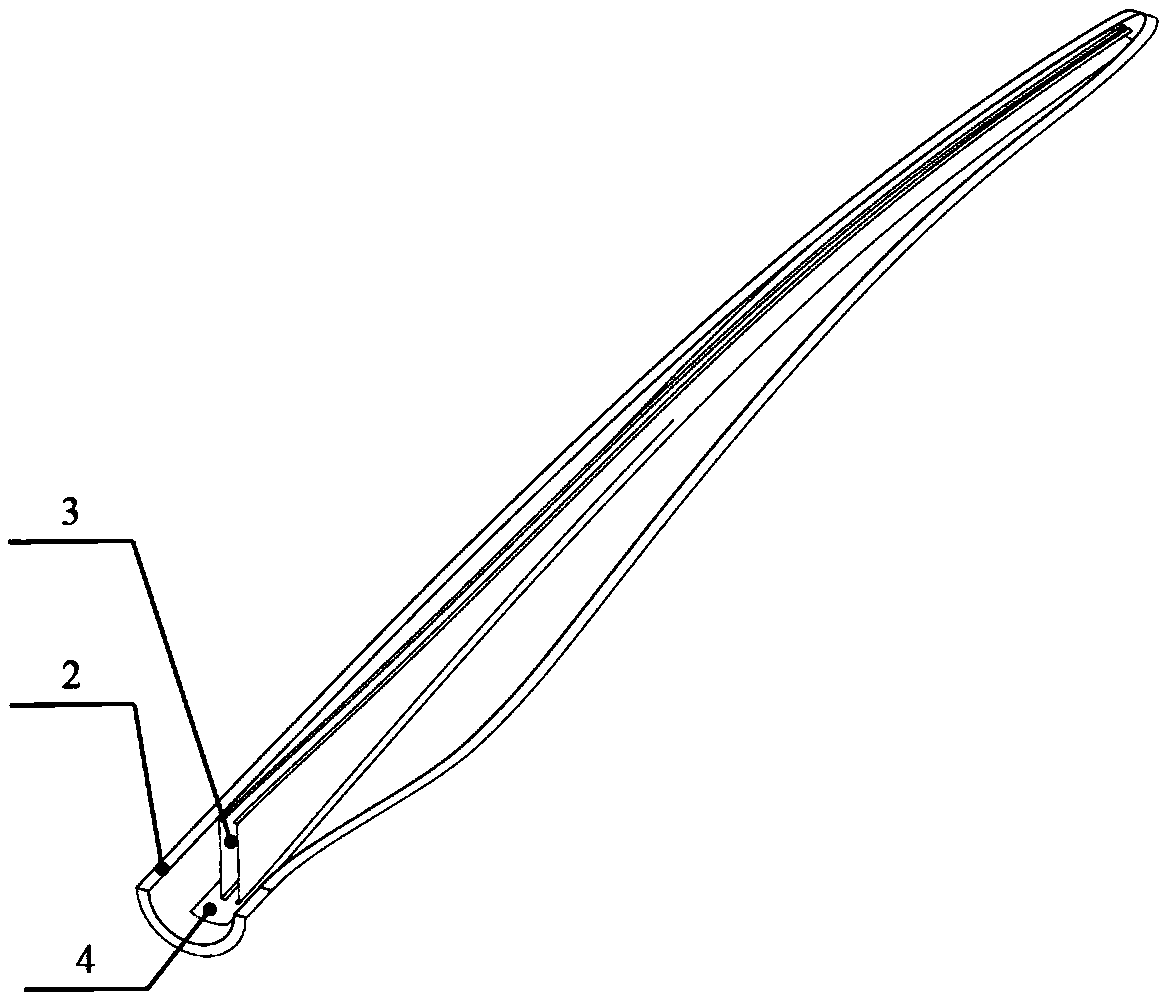

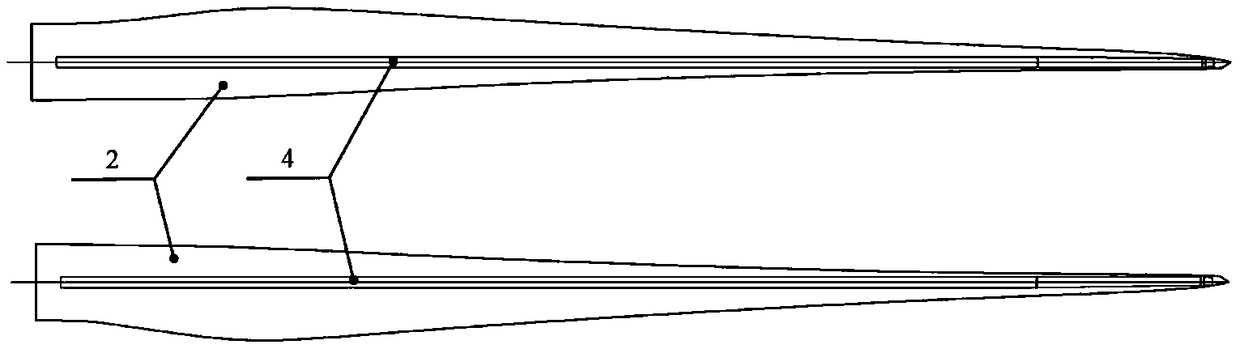

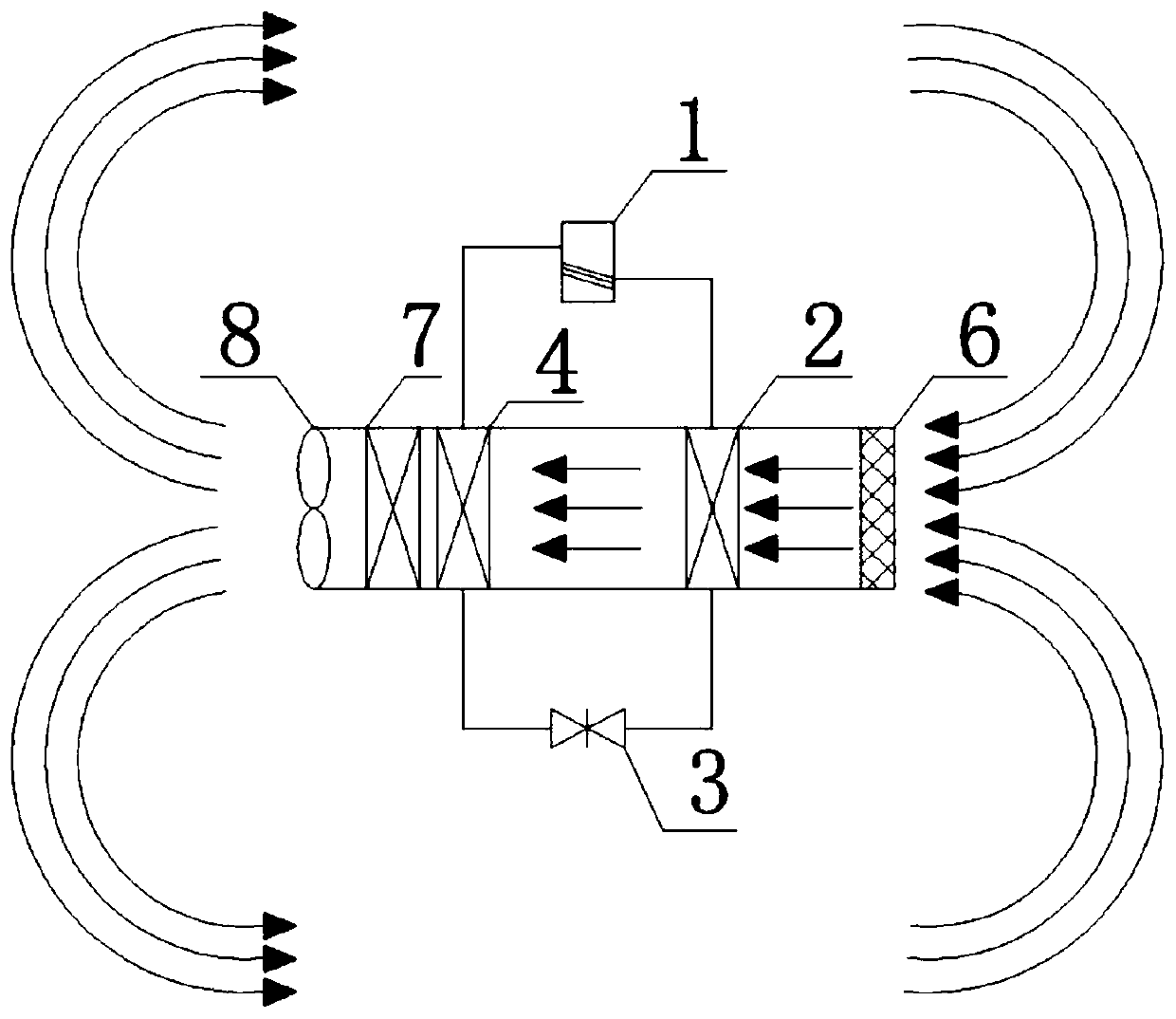

Preparation method of wind turbine blade

ActiveCN109109341AReduce the difficulty of bondingAvoid forming defects such as wrinklesDomestic articlesSuction stressTurbine blade

The invention discloses a preparation method of a wind turbine blade. The method comprises the following steps: laying fiberglass cloth, girders and a sandwich core in a suction side / pressure side shell mold, then carrying out vacuum resin infusion, solidifying and demoulding to obtain an integral body of shells and the girders; laying the fiberglass cloth, a core material and the fiberglass clothsequentially in a wind turbine blade prefabrication trailing edge mold, carrying out vacuum resin infusion, solidifying and demoulding to obtain a prefabricated trailing edge; molding the prefabricated trailing edge integrally by using the trailing edge of the suction side shell and the trailing edge of the pressure side shell; respectively sticking the two ends of a leading edge web and a trailing edge web with the suction side girder and the pressure side girder, and enabling the suction side shell to be partially stuck with the front edge part of the pressure side shell; sticking the prefabricated trailing edge with the suction side shell and the pressure side shell to obtain the wind turbine blade. The prefabricated trailing edge can be used for detailing control of a vertex, so thatthe molding defects such as folds are avoided to the utmost extent; the sticking surfaces of the prefabricated trailing edge and the shells are planes, so that the sticking difficulty is greatly reduced, and the quality is also guaranteed.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

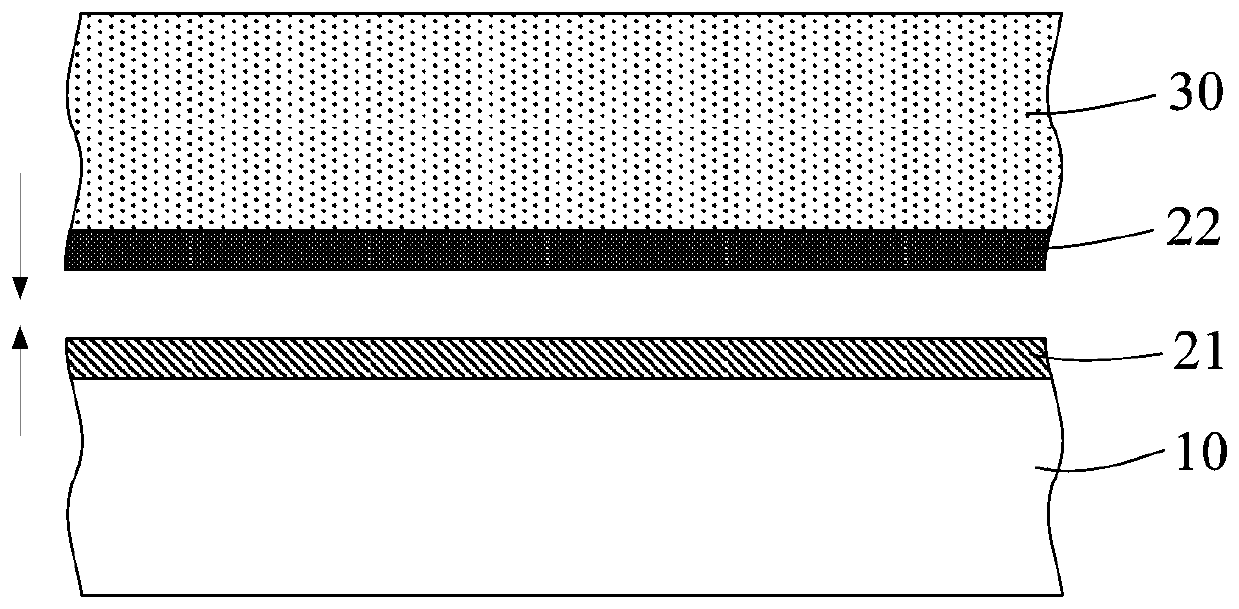

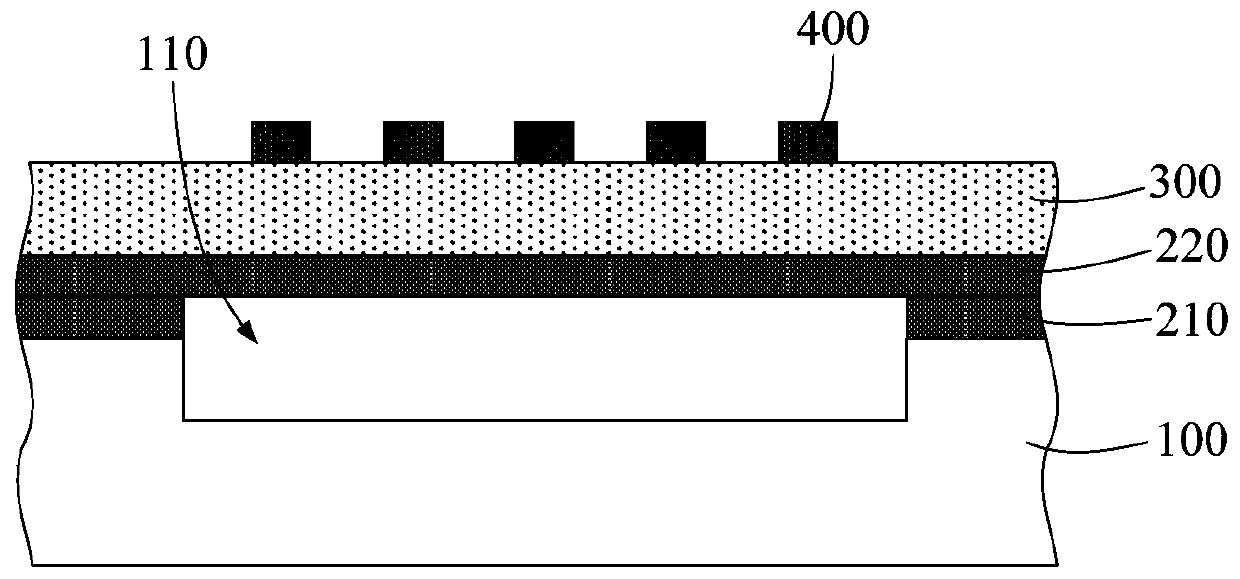

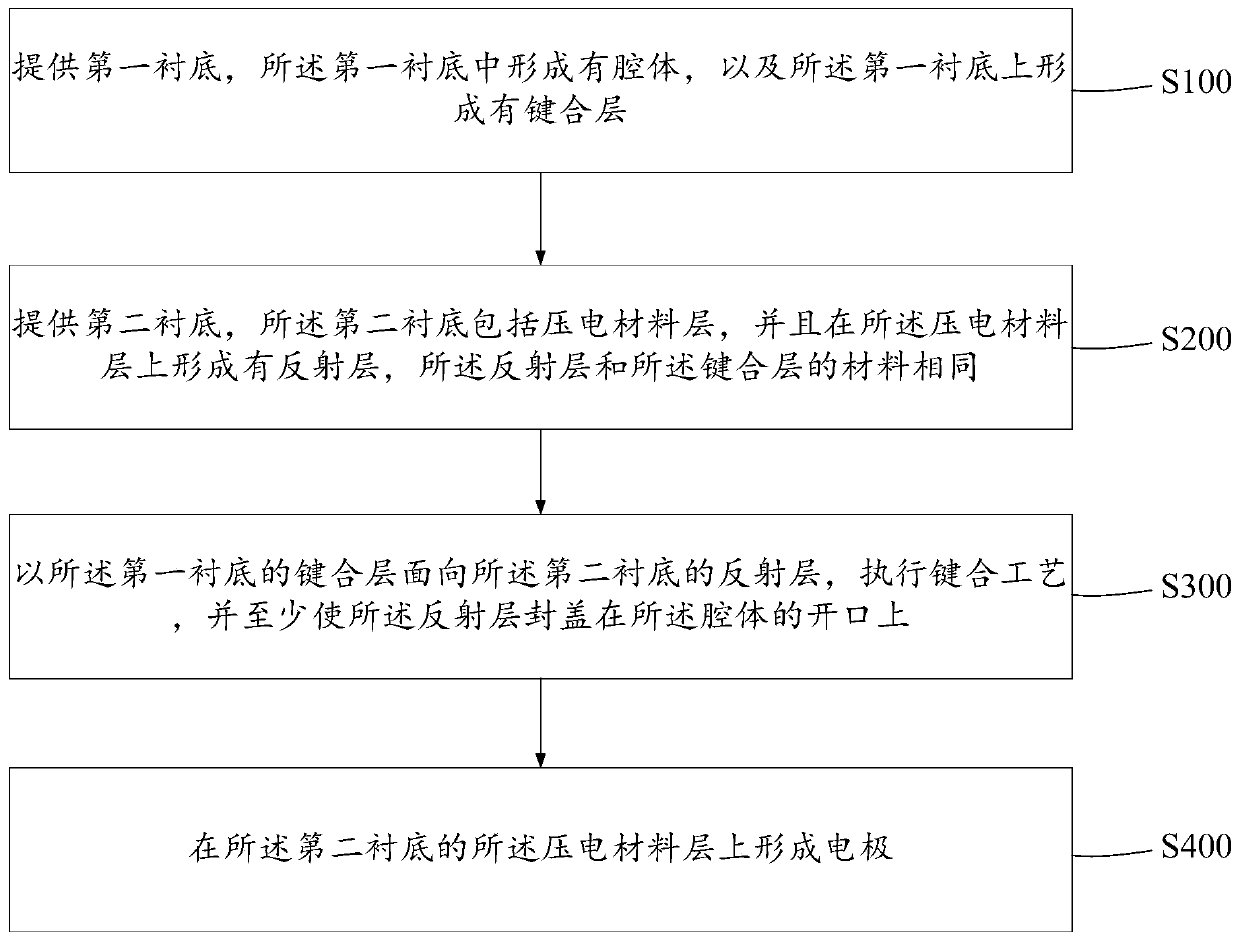

Surface acoustic wave resonator and forming method thereof

The invention provides a surface acoustic wave resonator and a forming method thereof. The surface acoustic wave resonator is not only provided with the reflecting layer, but also provided with the cavity, so that multiple reflections of sound waves propagating in the vertical direction can be realized, the loss of sound wave energy is reduced, and the Q value of the surface acoustic wave resonator is further improved. Moreover, the reflecting layer is bonded with the bonding layer made of the same material, so that the bonding layer and the reflecting layer are bonded more easily, the bondingstrength between the bonding layer and the reflecting layer can be improved, and the structural stability of the formed surface acoustic wave resonator is correspondingly improved.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

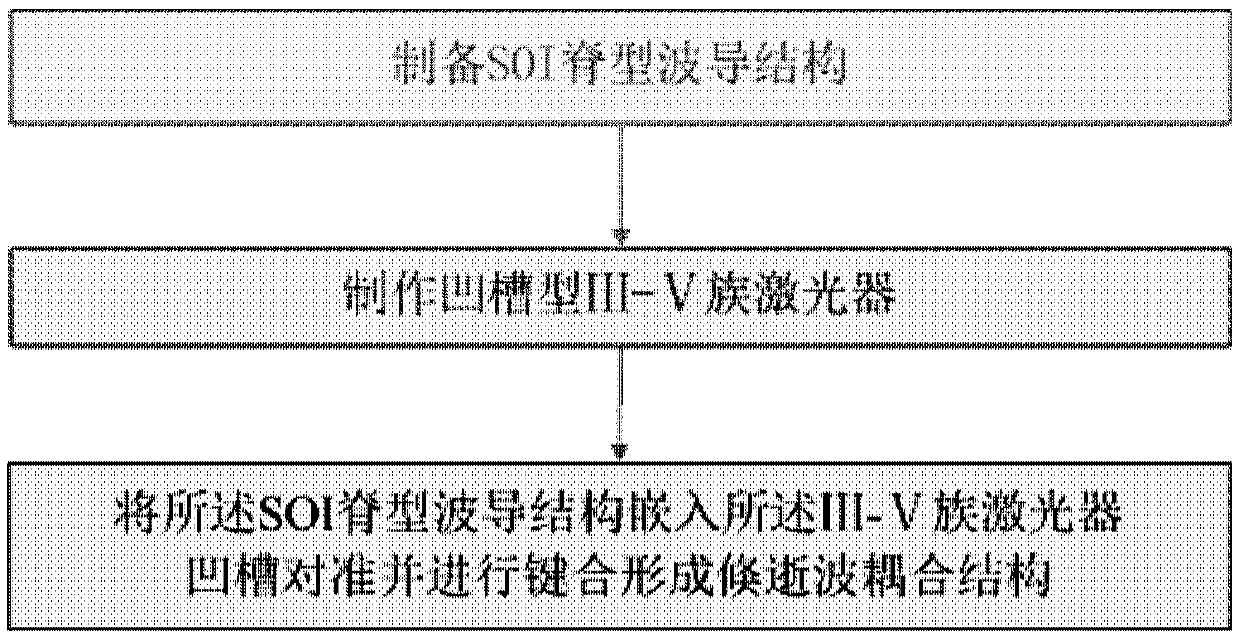

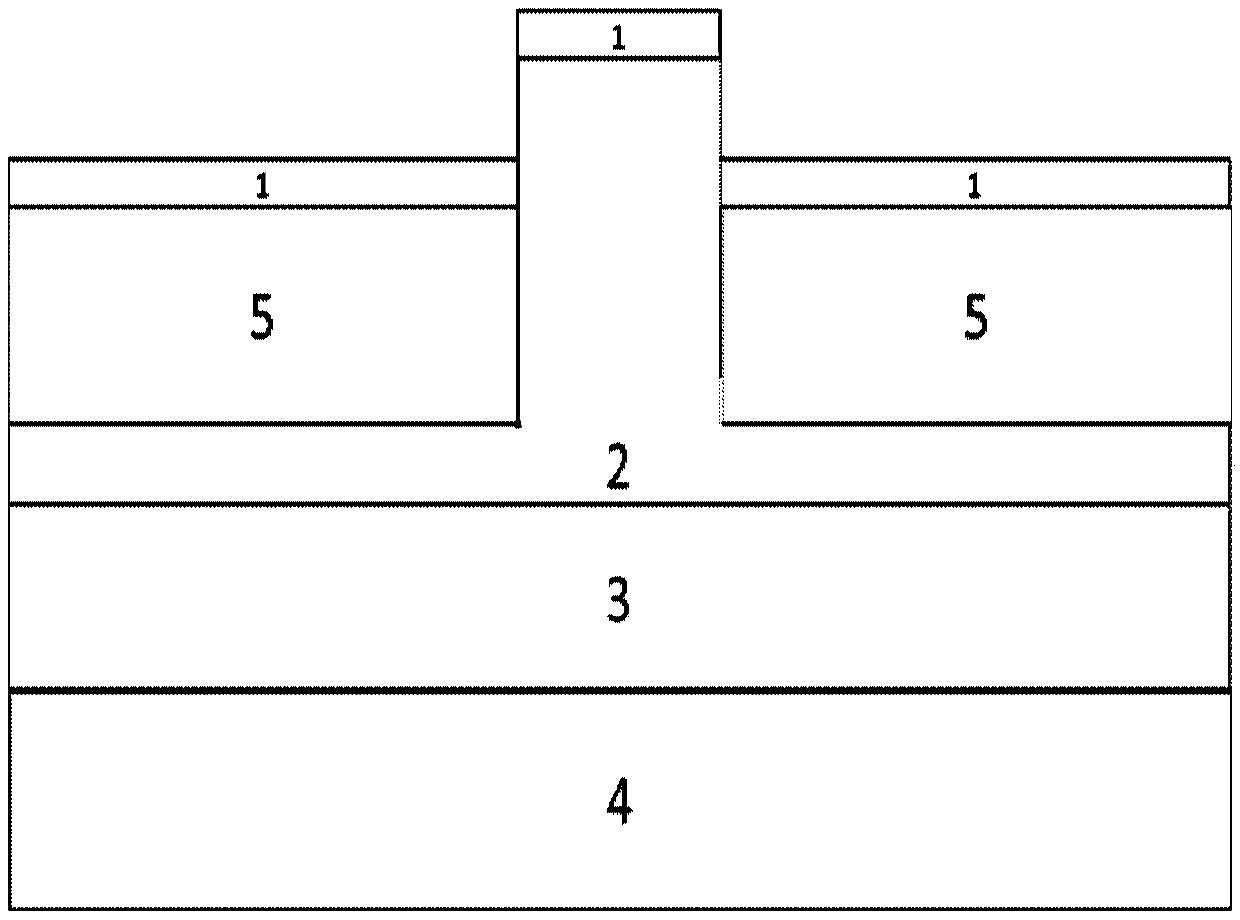

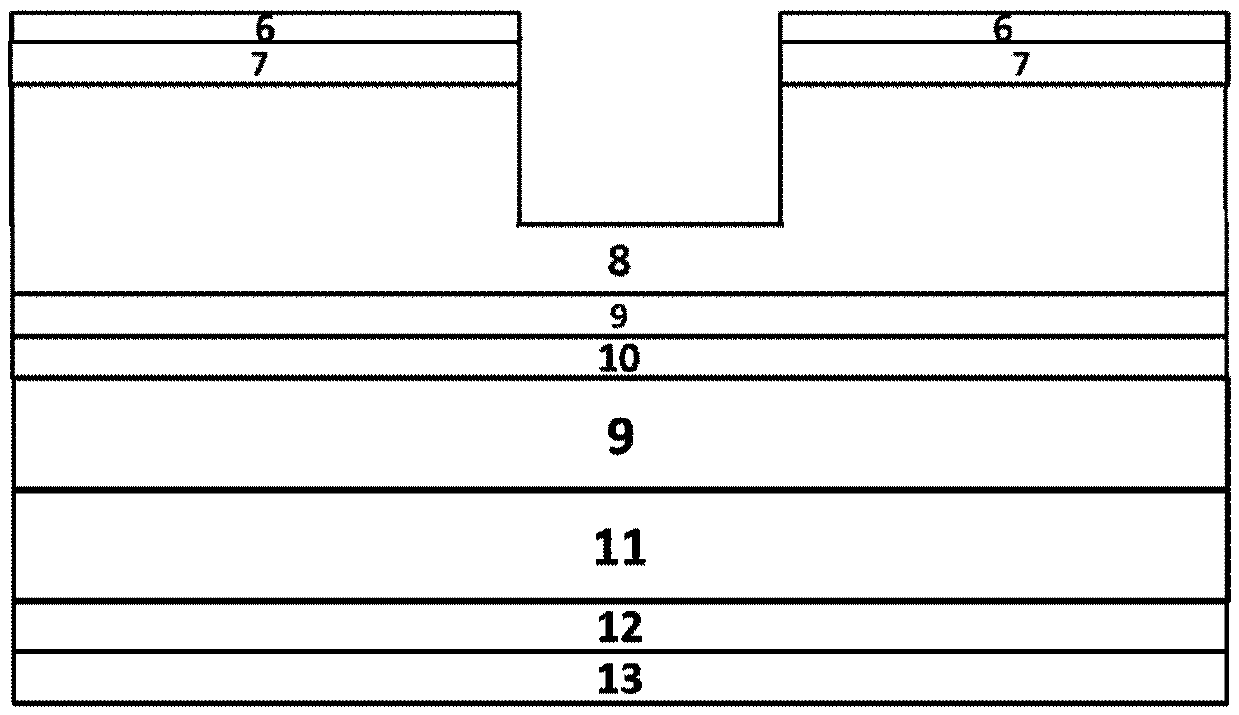

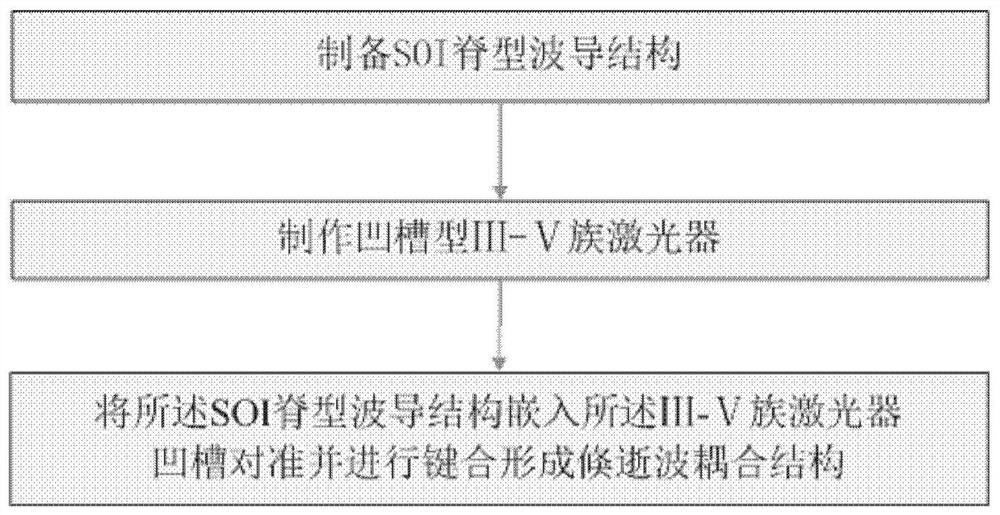

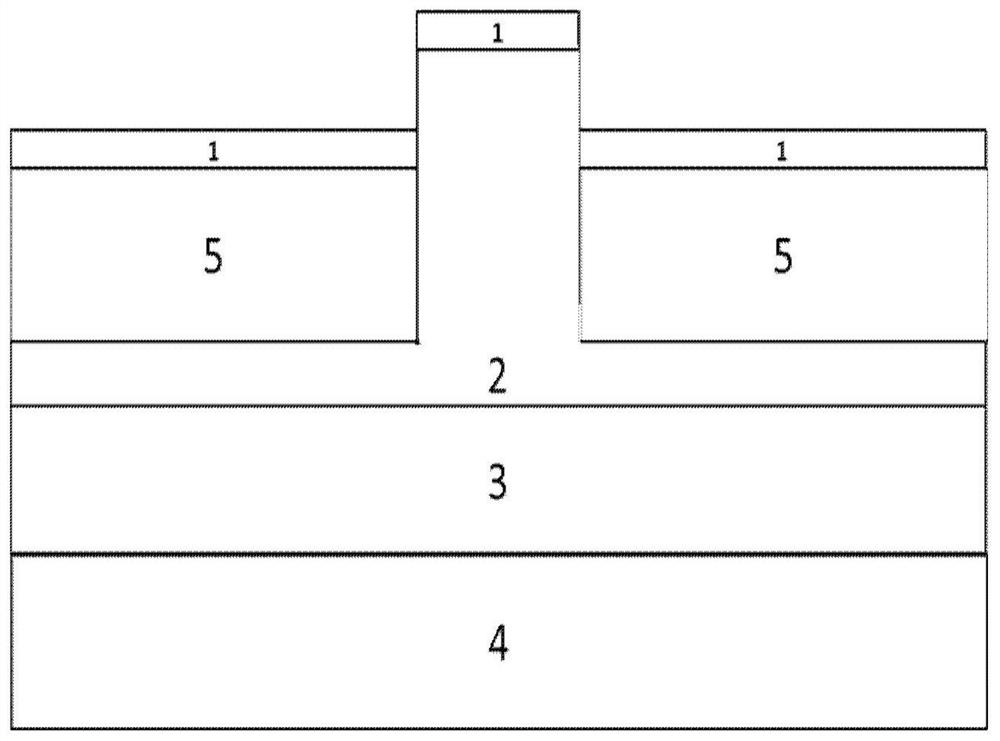

III-V group/silicon material slotting bonding laser structure and method thereof

ActiveCN111262132AImprove transmittanceReduce local feverOptical wave guidanceLaser detailsTransmittanceThin membrane

The invention discloses a III-V group / silicon material slotting bonding laser structure and a method thereof, which relate to the field of structural design of hybrid lasers. The method comprises thesteps of: preparing a ridge waveguide structure, manufacturing a groove type III-V group laser, and embedding the ridge waveguide structure into the III-V group laser groove for alignment and bonding,forming an evanescent wave coupling structure after bonding, and coupling and outputting laser light from an SOI waveguide port. The laser with a slotted structure is coupled with the silicon-based device, and a slotted embedded structure is adopted in the longitudinal direction, so that the spatial offset distance of the silicon-based transmission device is limited in the transverse direction, the bonding strength is improved, and the bonding difficulty is reduced; in addition, the ZnO transparent conductive thin film is used for assisting in bonding the hybrid laser, ZnO has good transmittance, and a low-resistance conductive layer can be formed after the high-temperature thin film is formed.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

Power module and packaging method thereof

InactiveCN110176451ALow costSimple packaging processSemiconductor/solid-state device detailsSolid-state devicesHigh densityComputer module

The invention provides a power module and a packaging method thereof. The power module comprises a bearing plate; the bearing plate comprises an insulating layer and a metal layer arranged on one surface of the insulating layer; and the power module further comprises at least one power chip and at least one driving chip, which are attached to the surface, far away from the insulating layer, of themetal layer, and are electrically connected with the metal layer through bonding wires. The power chips, the driving chips and pins are attached to the metal layer of the bearing plate, namely, a high-density lead frame and a PCB used in the prior art are replaced with the bearing plate, so that the cost is greatly reduced and the packaging process is simplified.

Owner:EDGELESS SEMICON CO LTD OF ZHUHAI

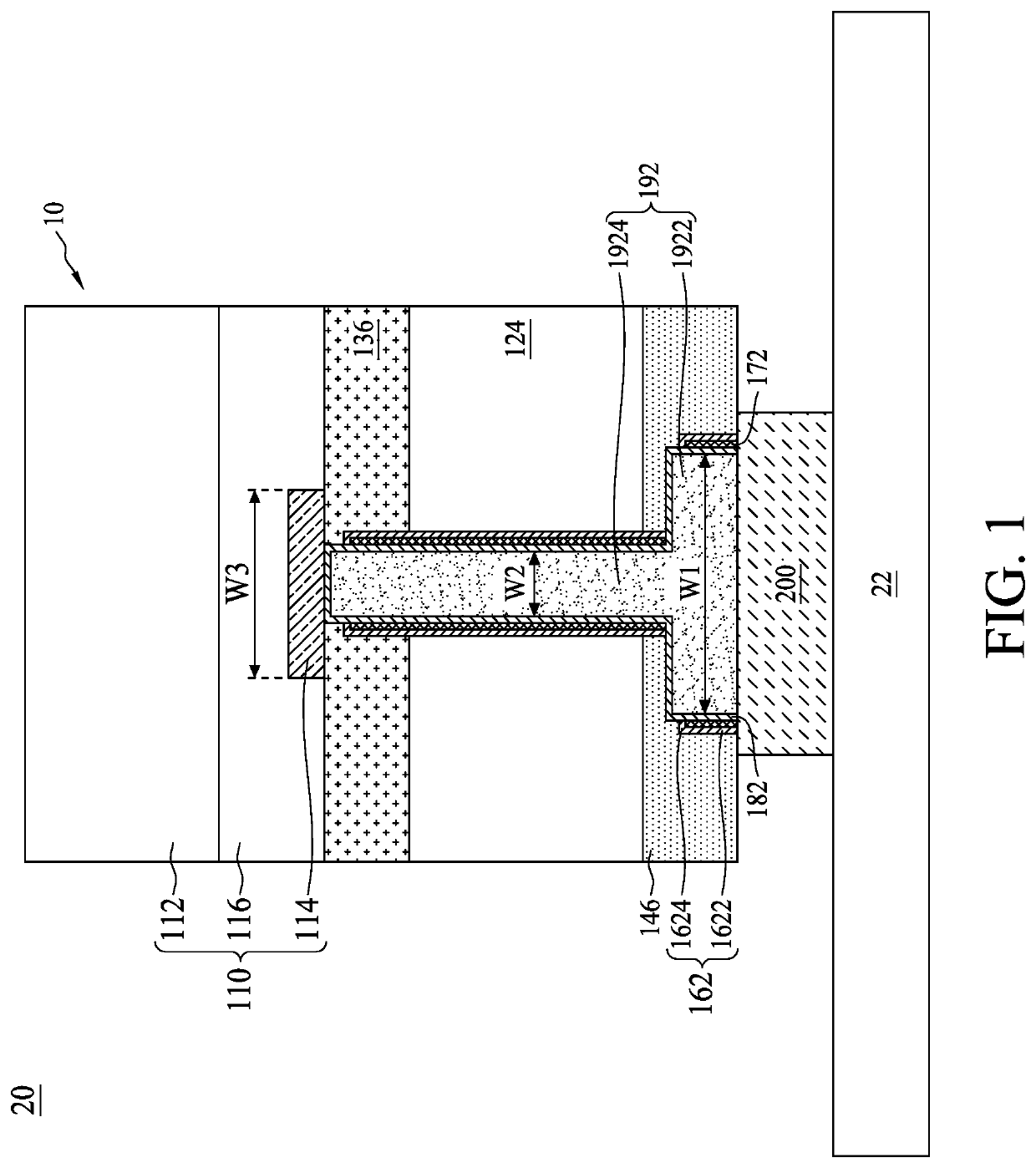

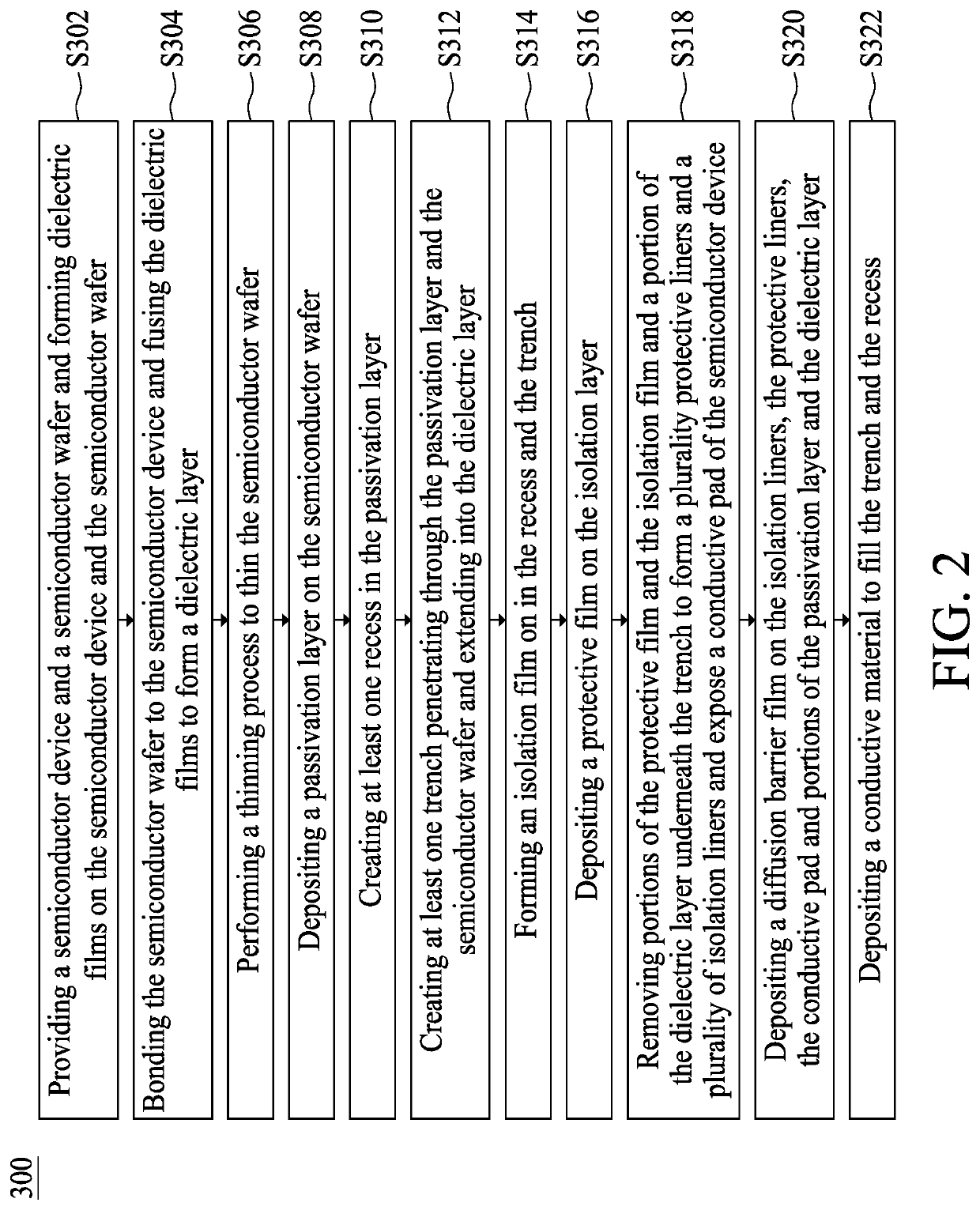

Semiconductor assembly having t-shaped interconnection and method of manufacturing the same

ActiveUS20210287981A1Increase footprintReduce difficultySemiconductor/solid-state device detailsSolid-state devicesPhysicsElectrically conductive

The present disclosure provides a semiconductor assembly and method of manufacturing the same. The semiconductor assembly includes a semiconductor device, a bulk semiconductor, a passivation layer, at least one conductive plug, a plurality of protective liners, and a plurality of isolation liners. The bulk semiconductor is disposed over the semiconductor device. The passivation layer covers the bulk semiconductor. The conductive plug comprises a first block disposed in the passivation layer and a second block disposed between the first block and the conductive pad, wherein portions of peripheries of the first and second blocks of the conductive plug are surrounded by the protective liners and the isolation liners.

Owner:NAN YA TECH

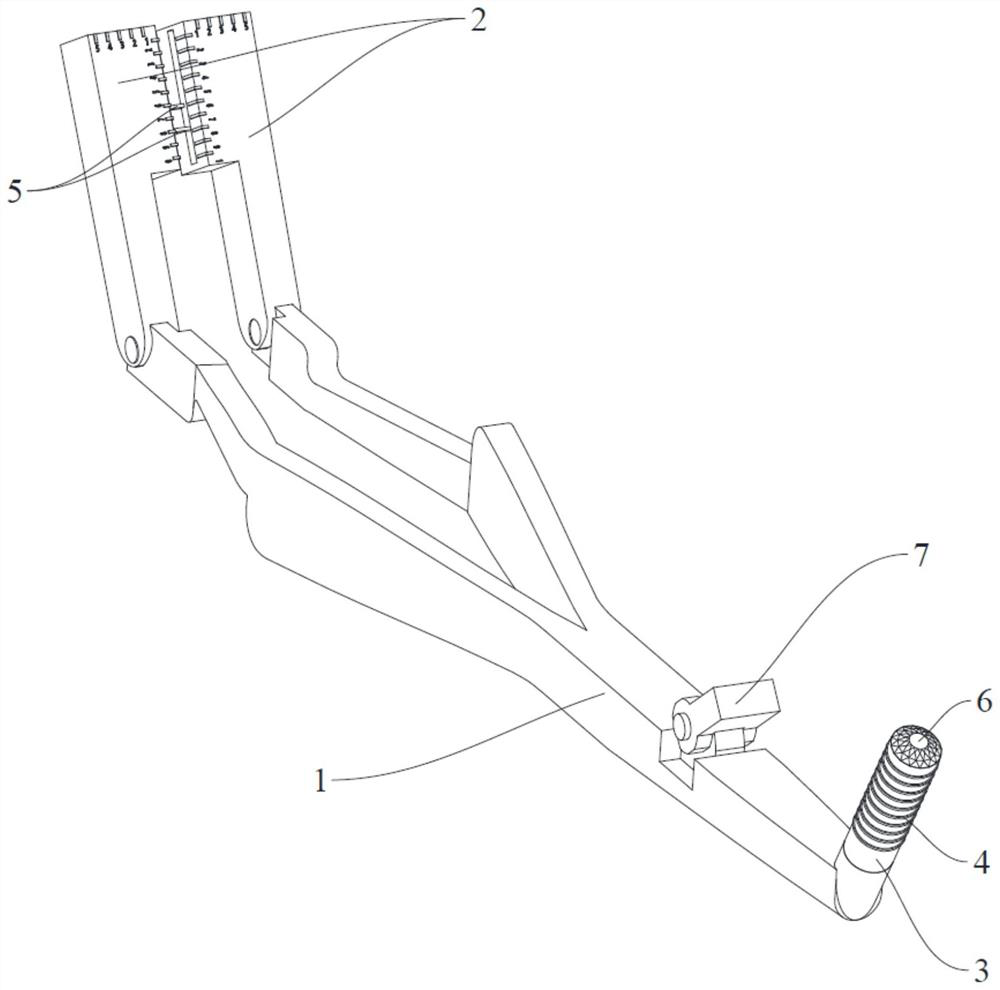

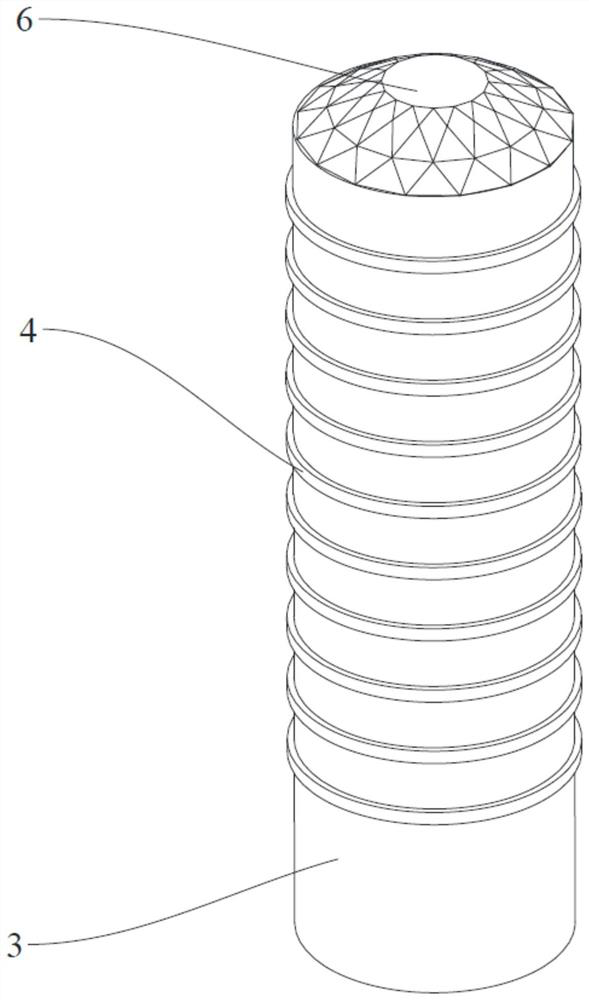

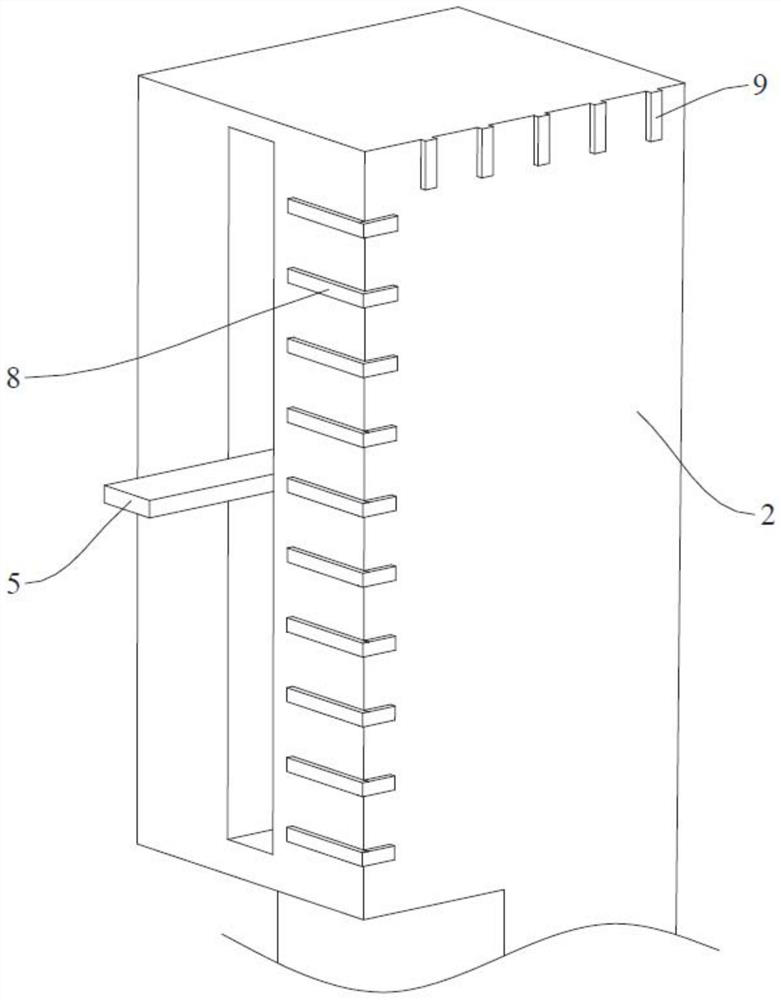

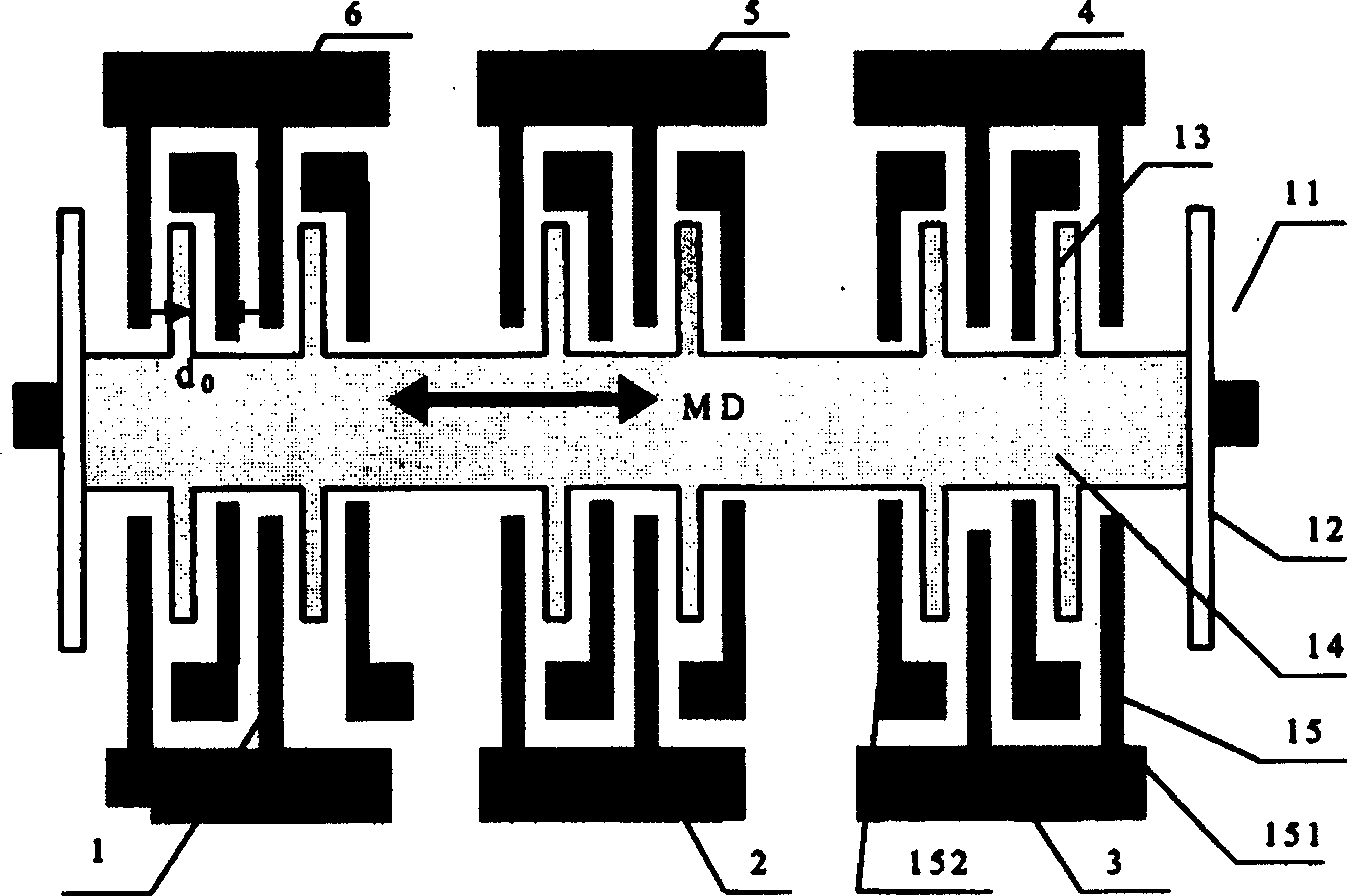

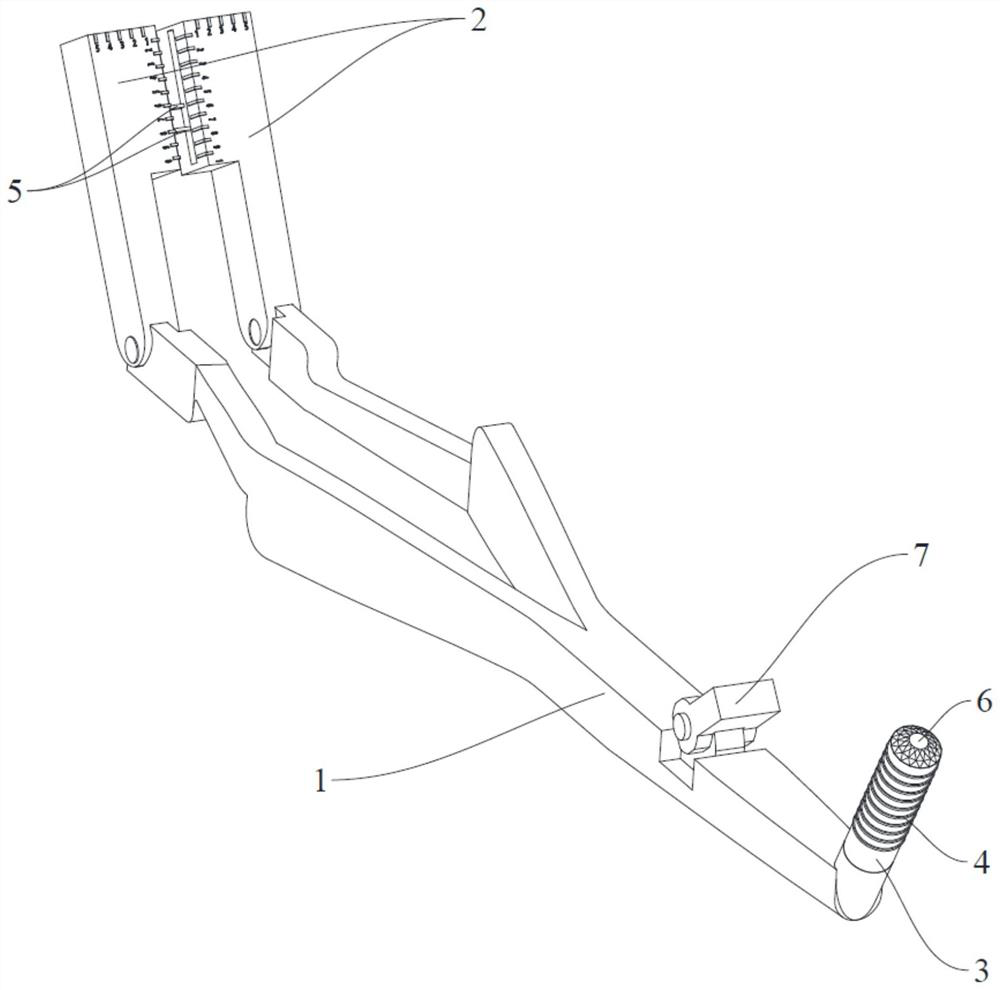

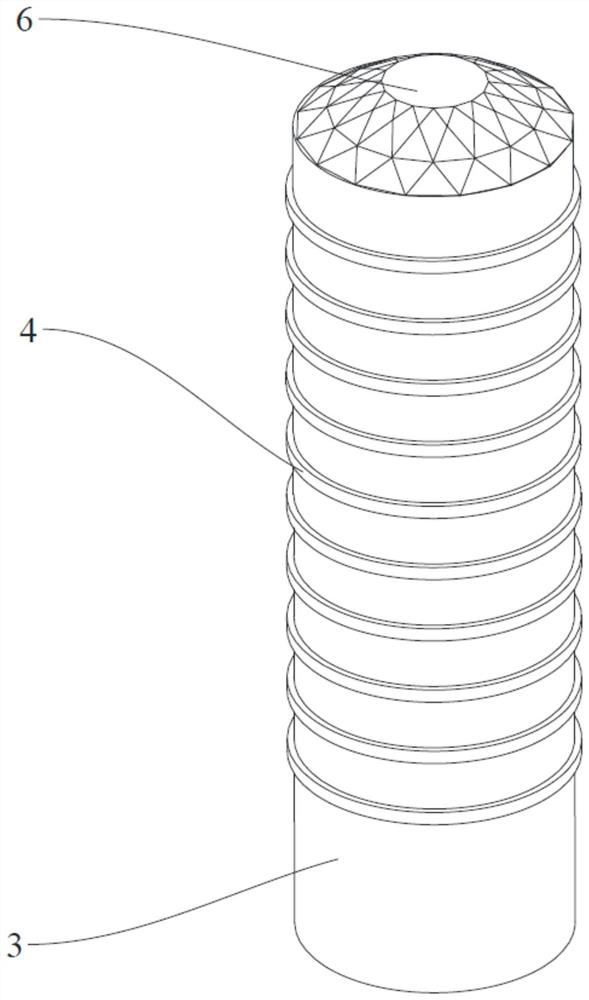

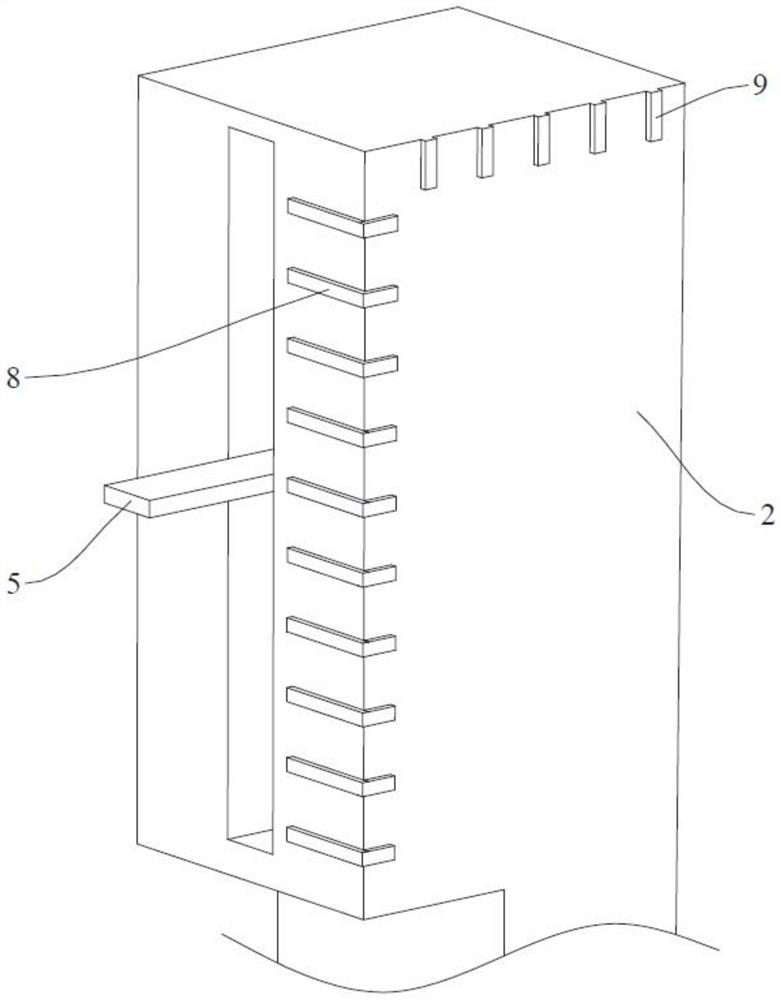

Bonding fixture of flexible gyroscopic moment skeleton coil

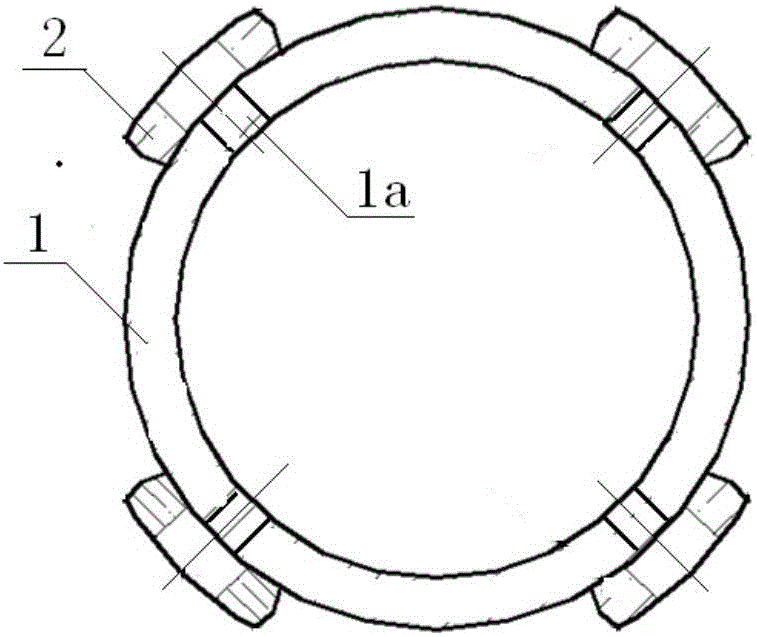

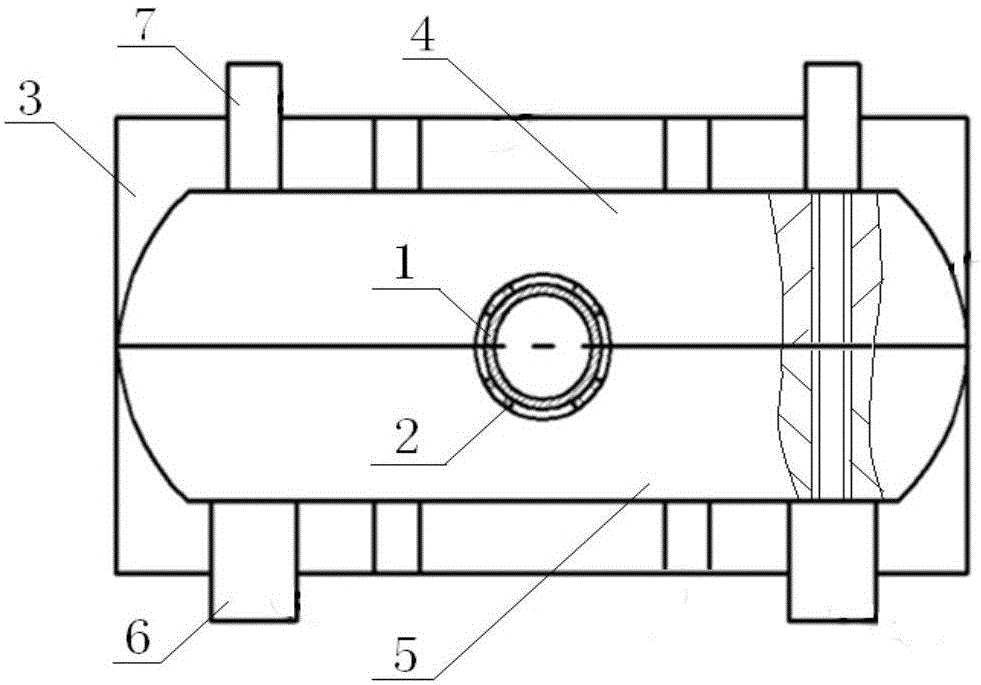

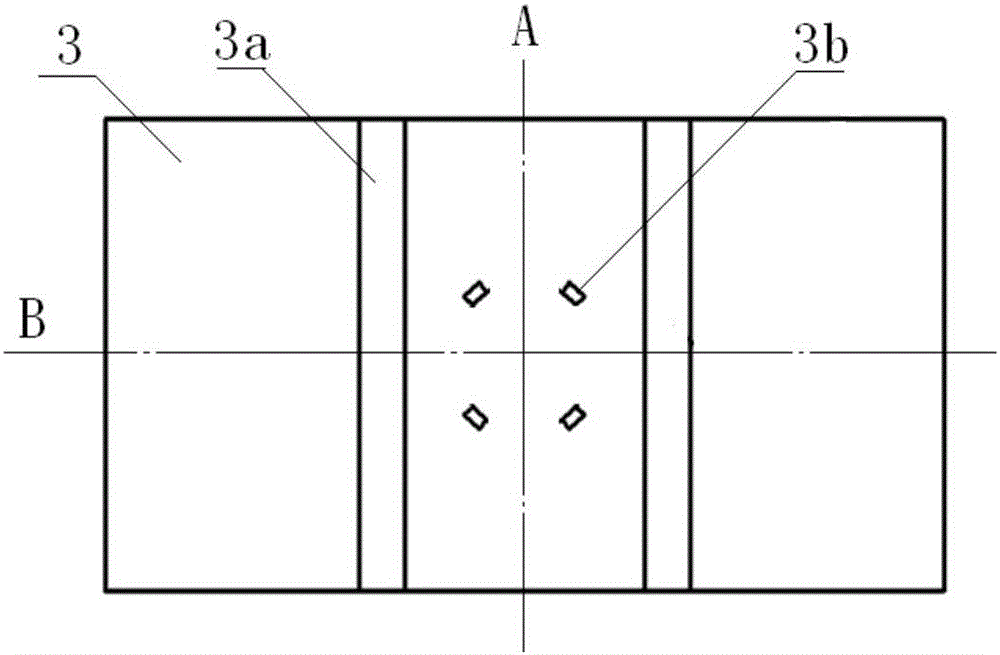

ActiveCN106392938AReduce the difficulty of bondingShorten the processing cycleMaterial gluingWork holdersGyroscopic momentEngineering

The invention belongs to a flexible top assembly technology, and relates to a bonding fixture of a flexible gyroscopic moment skeleton coil. The bonding fixture is characterized by consisting of a base (3), an upper clamping plate (4), a lower clamping plate (5) and two clamping bolt pairs. The bonding fixture of the flexible gyroscopic moment skeleton coil largely reduces the bonding difficulty, shortens the machining period, and improves the product pass percent.

Owner:LANZHOU FLIGHT CONTROL

Micro light-emitting-diode display panel and manufacturing method thereof

ActiveUS10263138B2Reduce the difficulty of bondingImprove reliabilitySolid-state devicesSemiconductor devicesEngineeringResin adhesive

The present invention provides a micro light-emitting-diode display panel and a manufacturing method thereof. The micro light-emitting-diode display panel which presses and fixes the micro light-emitting-diodes into a resin adhesive layer by filling the resin adhesive layer in the pixel groove. Meanwhile, the electrode at the bottom of the micro light-emitting-diode is guided to the top of the micro light-emitting-diode by the connection electrode, making the two electrodes of the micro light-emitting-diode are at the top, to facilitate the connection between the electrodes of the micro light-emitting-diode and the electrode points, which can reduce the difficulty of the electrode bonding of the micro light-emitting-diode, and improve the reliability of the electrode bonding of the micro light-emitting-diode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

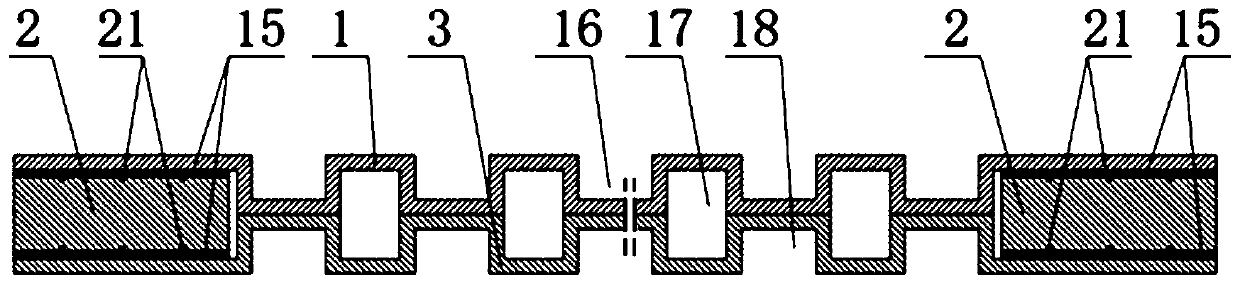

Fuel cell metal bipolar plate

The invention relates to a fuel cell metal bipolar plate which comprises a cathode plate (1) and an anode plate (3) which are formed by stamping a single-layer metal sheet. A plurality of grooves punched in the front surface of the cathode plate (1) form an oxidant flow channel (16); protruding parts on the peripheries of the grooves form oxidizing agent flow channel walls. A plurality of groovespunched in the front face of the anode plate (3) form a fuel flow channel (18), wherein the protruding parts between the grooves form fuel flow channel walls; grooves are formed in the back faces of the protruding parts on the front faces of the anode plate (1) and the cathode plate (3) respectively, and back face protruding ridges are formed on the groove parts on the front faces respectively. The cathode plate (1) and the anode plate (3) are assembled in a back-to-back clinging manner, wherein the groove and the convex ridge on the back surface are coupled to form a groove-to-groove or groove-to-ridge cooling liquid flow channel (17). Compared with the prior art, the bipolar plate is compact in structure, ultrathin, good in conductivity, easy to process, low in cost, stable in structureand good in sealing performance.

Owner:氢鑫沃德(上海)新能源发展有限公司

Drying method and preparation method for lost foam

ActiveCN110102709ANot prone to cracking problemsAvoid destructionFoundry mouldsFoundry coresAgricultural engineeringSaturated water vapor

The invention discloses a drying method for a lost foam, and the drying method comprises the following steps of: step 1, sending a coated foam mold to a coating drying room, and pre-drying the coatedfoam mold under the condition of circulating hot air, wherein the temperature of the circulating hot air is 30-35 DEG C, the wind speed is 1.5M / S-2.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidityof the drying room is 30%-35%, and the drying time is 2h-3h; step 2, sending the foam mold pre-dried in the step 1 to a stokehold drying room, and drying the foam mold under the condition of the circulating hot air, wherein the temperature of the circulating hot air is 30-50 DEG C, the wind speed is 0.5M / S-1.5M / S, the wind pressure is 0.1Pa-0.6Pa, the humidity of the drying room is 15%-20%, and the drying time is 6h-8h. The invention further discloses a preparation method for the lost foam. The invention has the organic combination of realizing the humidity, the flow of air and the temperature, prevents the saturated water vapor in the coating from being in an expanded state, and the water loss outside the coating being dried and shrunk quickly to cause the phenomenon of coating cracking.

Owner:安徽南凯元机械有限公司

Touch screen and display device

InactiveUS20200174640A1Reduce circuit sizeReduce in quantityInput/output processes for data processingCapacitanceDisplay device

Provided are a touch screen and a display device. The touch screen includes: thin film transistors and touch control electrodes disposed on the substrate, and the substrate includes signal channels for transmitting or receiving the touch control electrode capacitive signal in time division and control channels for controlling on and off of the thin film transistors; sources of at least two of the thin film transistors connect one signal trace to one signal channel; gates of the at least two of the thin film transistors connect one control trace to one control channel; one touch control electrode is connected to a drain of one thin film transistor.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Manufacturing method of micro display device

PendingCN114335058AReduce the difficulty of bondingSolid-state devicesSemiconductor devicesThermal dilatationWafer

According to the manufacturing method of the micro-display device provided by the invention, the positive or negative three-dimensional structures are prepared on a pair of wafers to be bonded respectively, the two wafers are pre-bonded under the action of alignment and pressure, and the pre-bonding process is carried out at normal temperature, so that the temperature influence is avoided, and even if a pair of heterogeneous wafers is bonded, the yield of the wafers is greatly improved. The metal plug and the metal pad are bonded by using a heating furnace after pre-bonding, and displacement caused by different thermal expansion coefficients is avoided, the sapphire substrate of the LED is peeled off by using laser after pre-bonding, and finally, the metal plug and the metal pad are bonded by using the heating furnace for heating and bonding.

Owner:JIHUA LAB

Bracket positioning device

The invention discloses a bracket positioning device. The bracket positioning device is used for positioning a bracket on a dental surface and comprises a holding piece, a probe, a positioning piece and an anti-abrasion piece, wherein a clamping piece is arranged at one end of the holding piece and used for clamping the bracket; the probe is connected with the other end of the holding piece; a scale identification part is arranged on the probe which is used for measuring the position information of the tooth surface; the positioning piece is arranged on the clamping piece and can position thebracket on the dental surface; and the anti-abrasion piece is connected with one end, far away from the holding piece, of the probe and is used for reducing abrasion of the probe. According to the bracket positioning device, the bonding efficiency and bonding accuracy of the bracket on the tooth surface can be improved; the bonding difficulty of the bracket is reduced; meanwhile, the orthodontic duration of a patient is effectively shortened.

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Touch OLED display panel and display device

InactiveUS20190229154A1Simple structureThin thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present disclosure discloses a touch OLED display panel including a flexible array substrate, a package cover and a display area; wherein a chip bonding portion and a first connection terminal are electrically connected to each other, a touch electrode and a second connection terminal are electrically connected to each other on a side of the package cover, the chip bonding portion and the first connection terminal are respectively located at two different sides outside the display area, and the first connection terminal and the second connection terminal are located at a same side outside the display area. A side of the flexible array substrate arranged with the first connection terminal is bent and connected to the package cover, and the second connection terminal and the first connection terminal are electrically connected to each other. The present disclosure further discloses a display device including the touch OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Micro light-emitting-diode display panel and manufacturing method thereof

ActiveUS20190181295A1Reduce the difficulty of bondingImprove reliabilitySolid-state devicesSemiconductor devicesEngineeringResin adhesive

The present invention provides a micro light-emitting-diode display panel and a manufacturing method thereof. The micro light-emitting-diode display panel which presses and fixes the micro light-emitting-diodes into a resin adhesive layer by filling the resin adhesive layer in the pixel groove. Meanwhile, the electrode at the bottom of the micro light-emitting-diode is guided to the top of the micro light-emitting-diode by the connection electrode, making the two electrodes of the micro light-emitting-diode are at the top, to facilitate the connection between the electrodes of the micro light-emitting-diode and the electrode points, which can reduce the difficulty of the electrode bonding of the micro light-emitting-diode, and improve the reliability of the electrode bonding of the micro light-emitting-diode.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

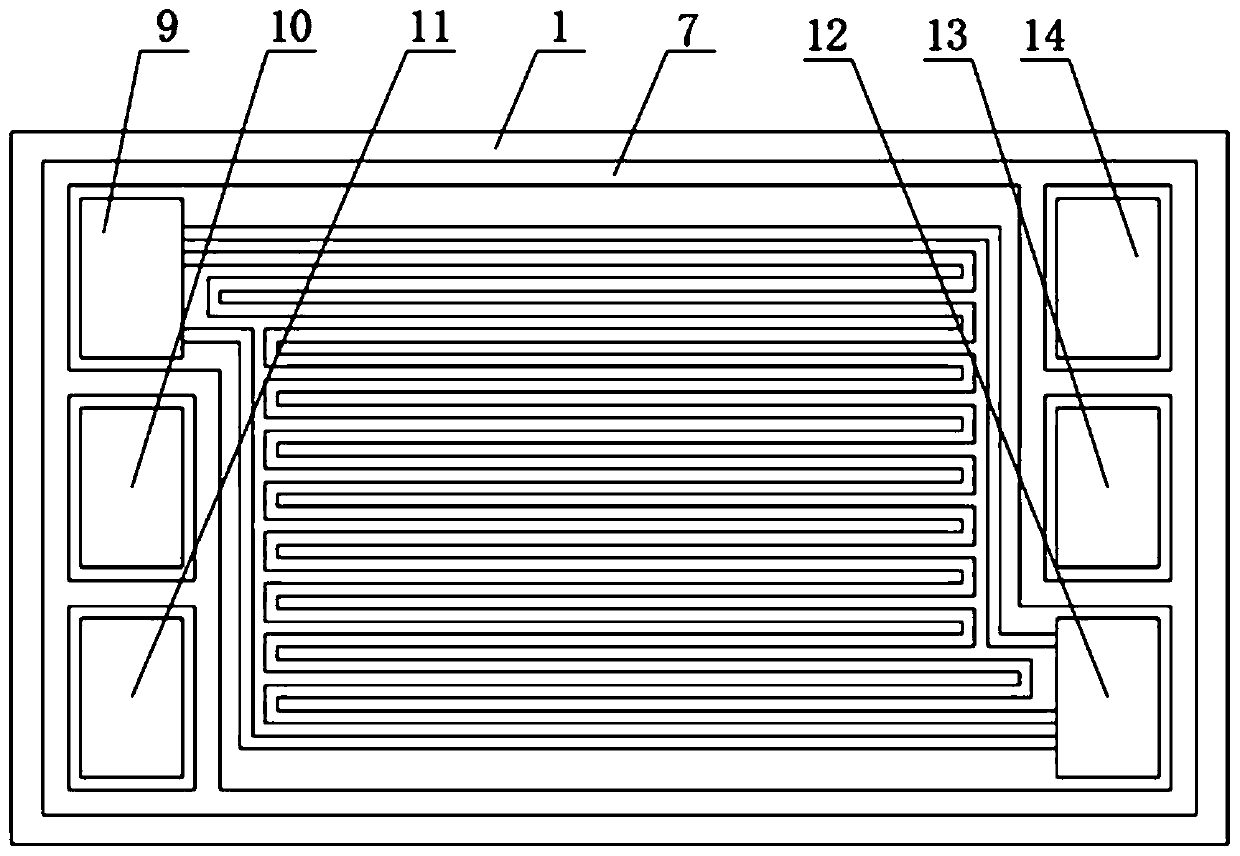

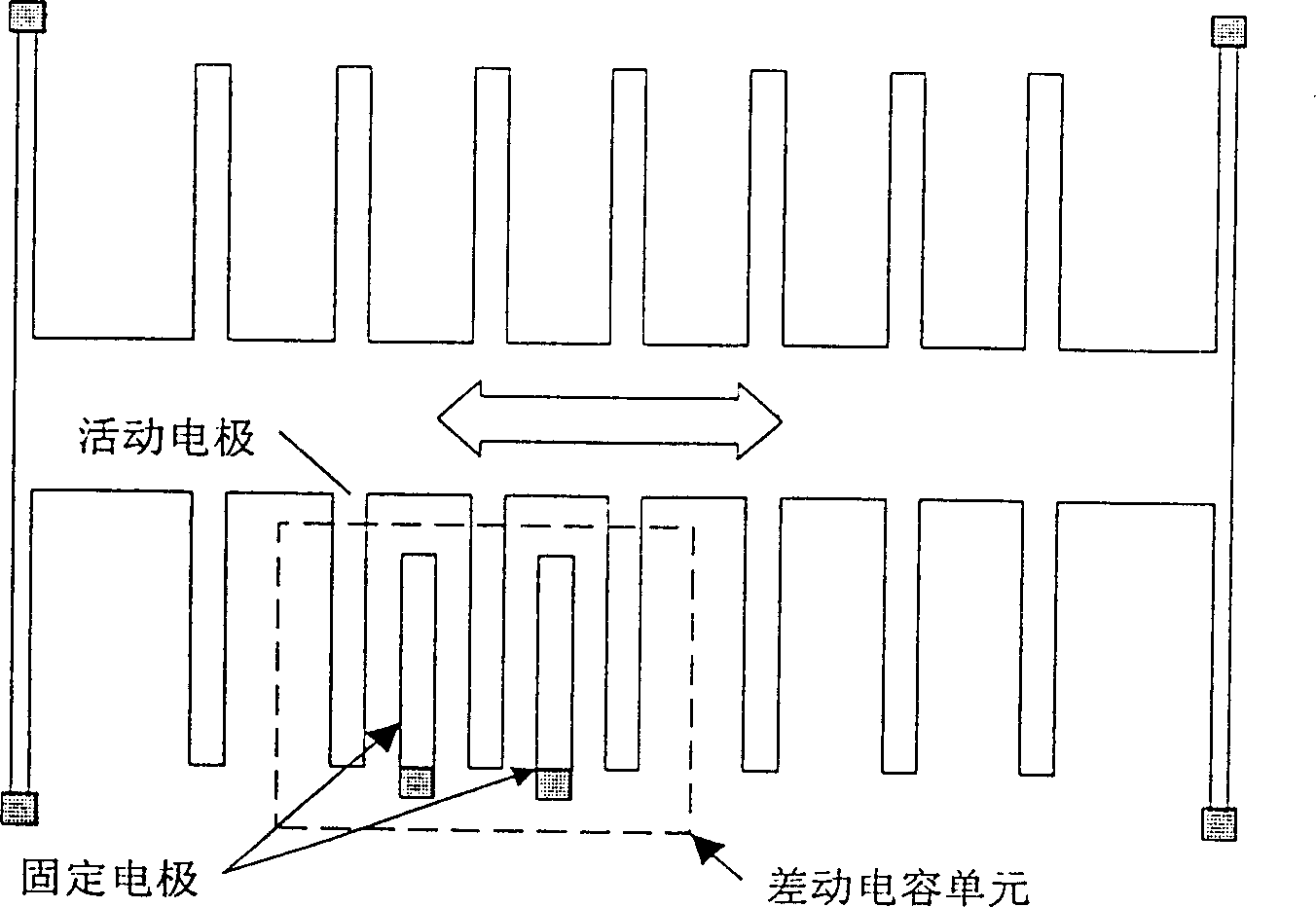

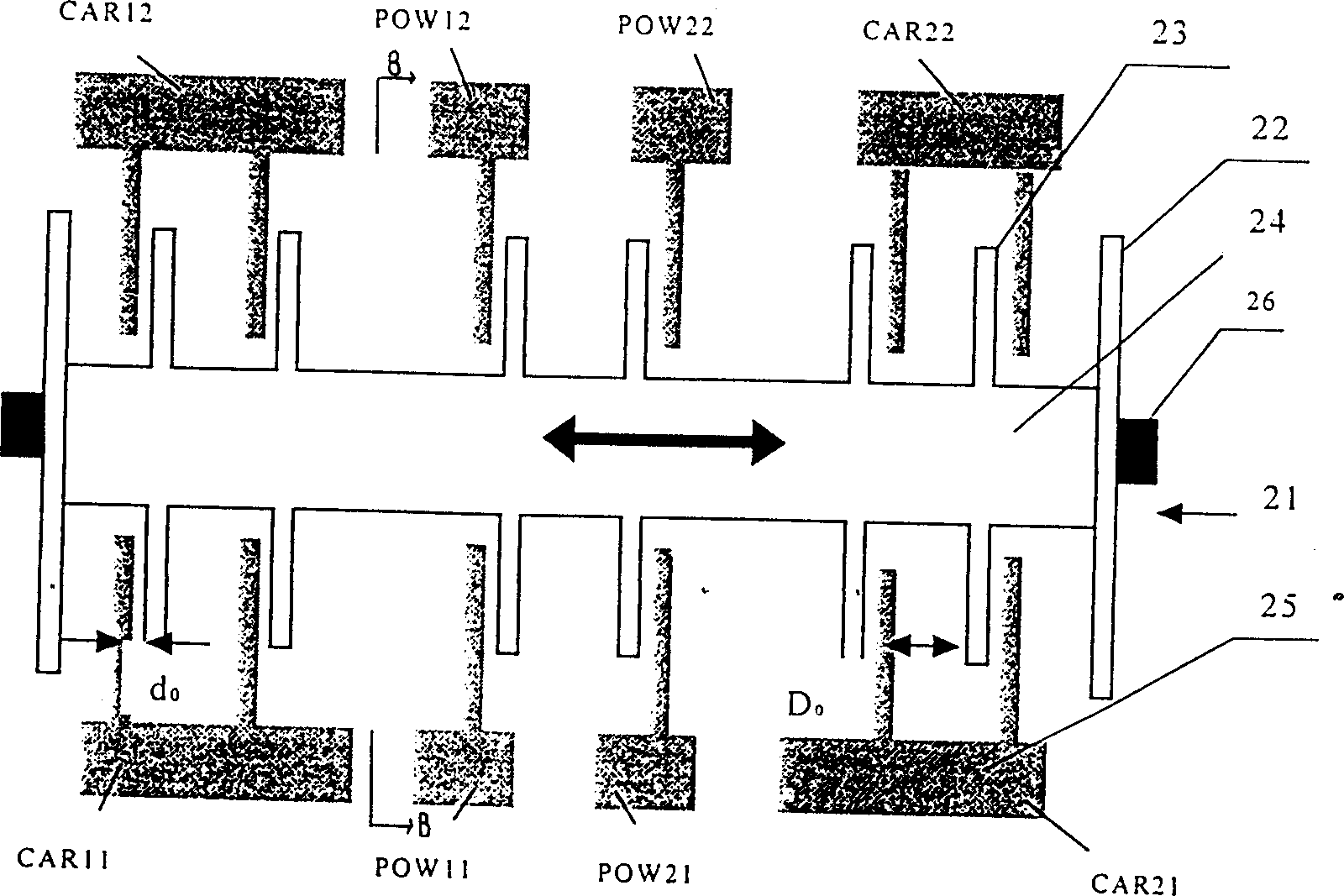

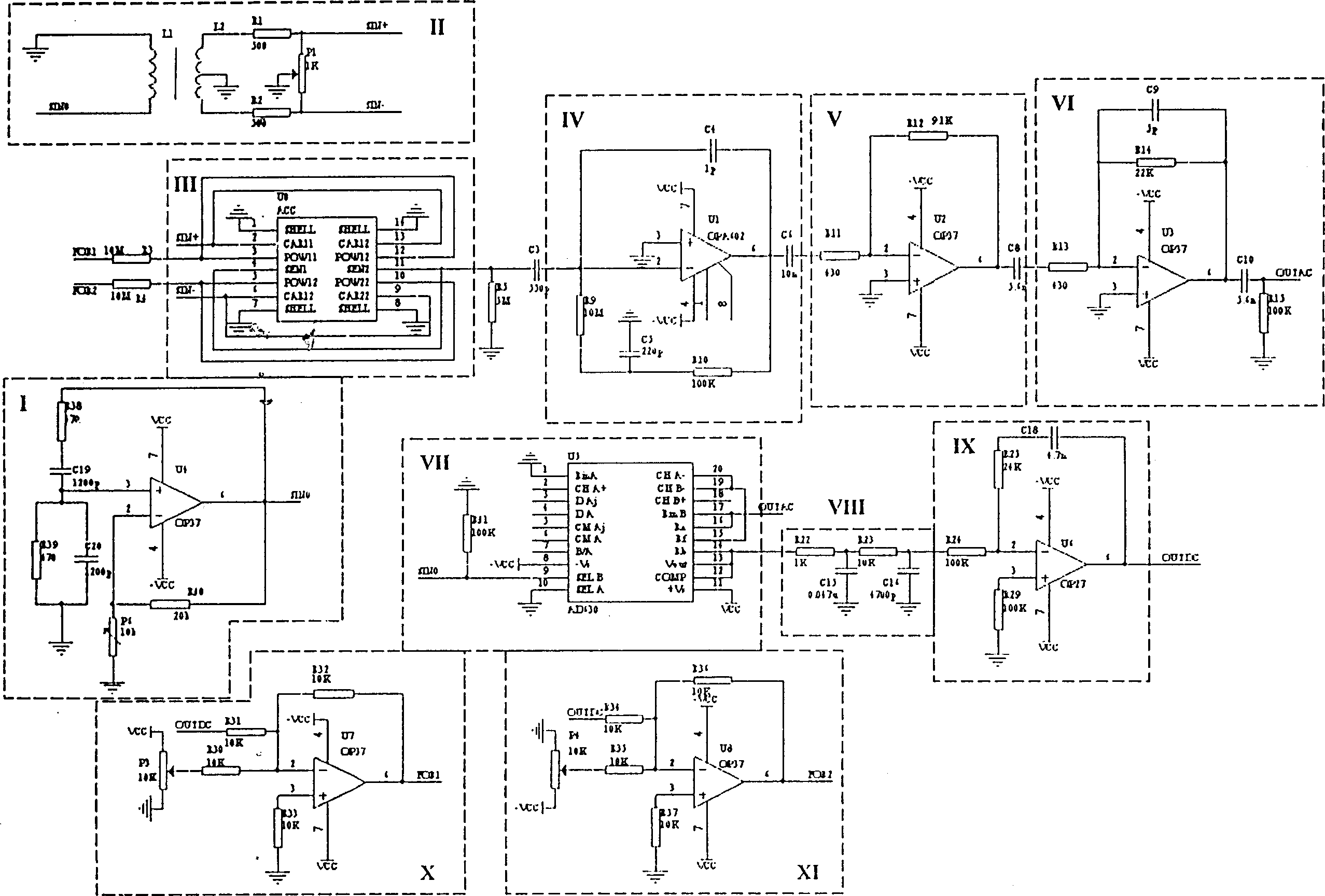

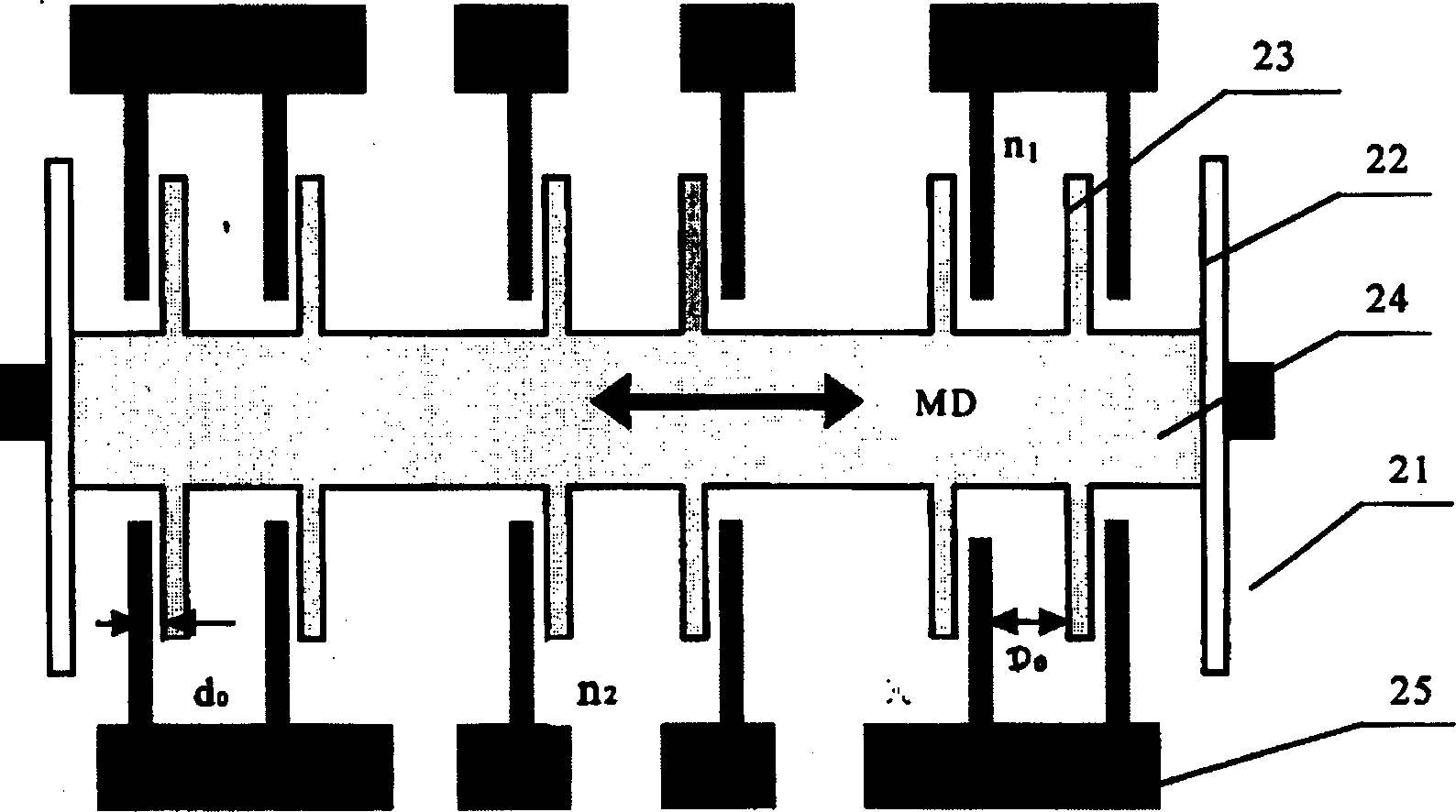

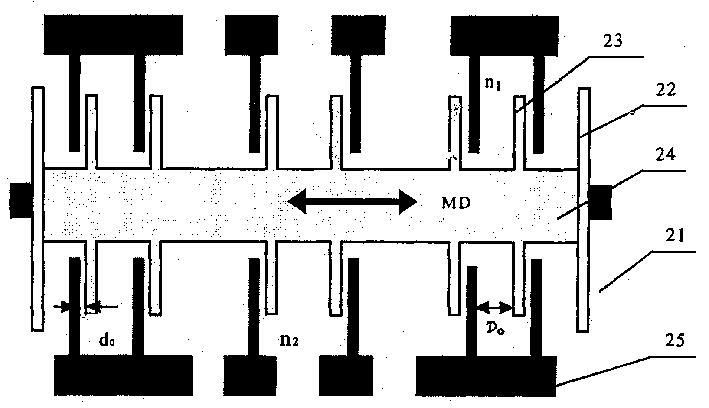

Comb teeth type body silicon working microchemical accelerometer

InactiveCN1139815CIncrease bonding areaReduce the difficulty of bondingAcceleration measurementCapacitanceAudio power amplifier

The structure of comb tooth type silicon processing micromachinery accelerometer includes the tooth comb formed by means of body processing, sensing quality element formed from several groups of moving teeth and folded beam group fixed tooth biased fixed tooth and substrate, and its circuit includes the portions of microcapacitor detection and force feedback servocircuit, etc. Said invention can develope the face-processed comb tooth structure into body-processed comb tooth sturcture by means of fixed tooth biased structure, and can increase detection and thrust capacitance so as to greatly raise its resolution and accuracy. Besides, in its preamplifier low input impedance circuit is used and in closed loop feedback thrust the differential D.C. voltage mode is used, so that it can make instrument possess high accuracy.

Owner:TSINGHUA UNIV

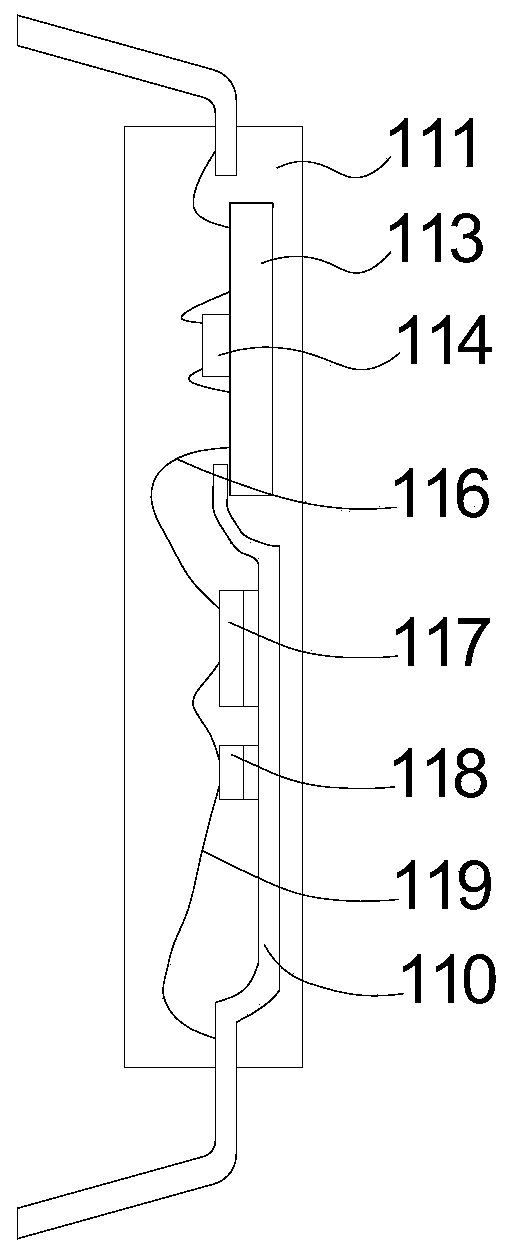

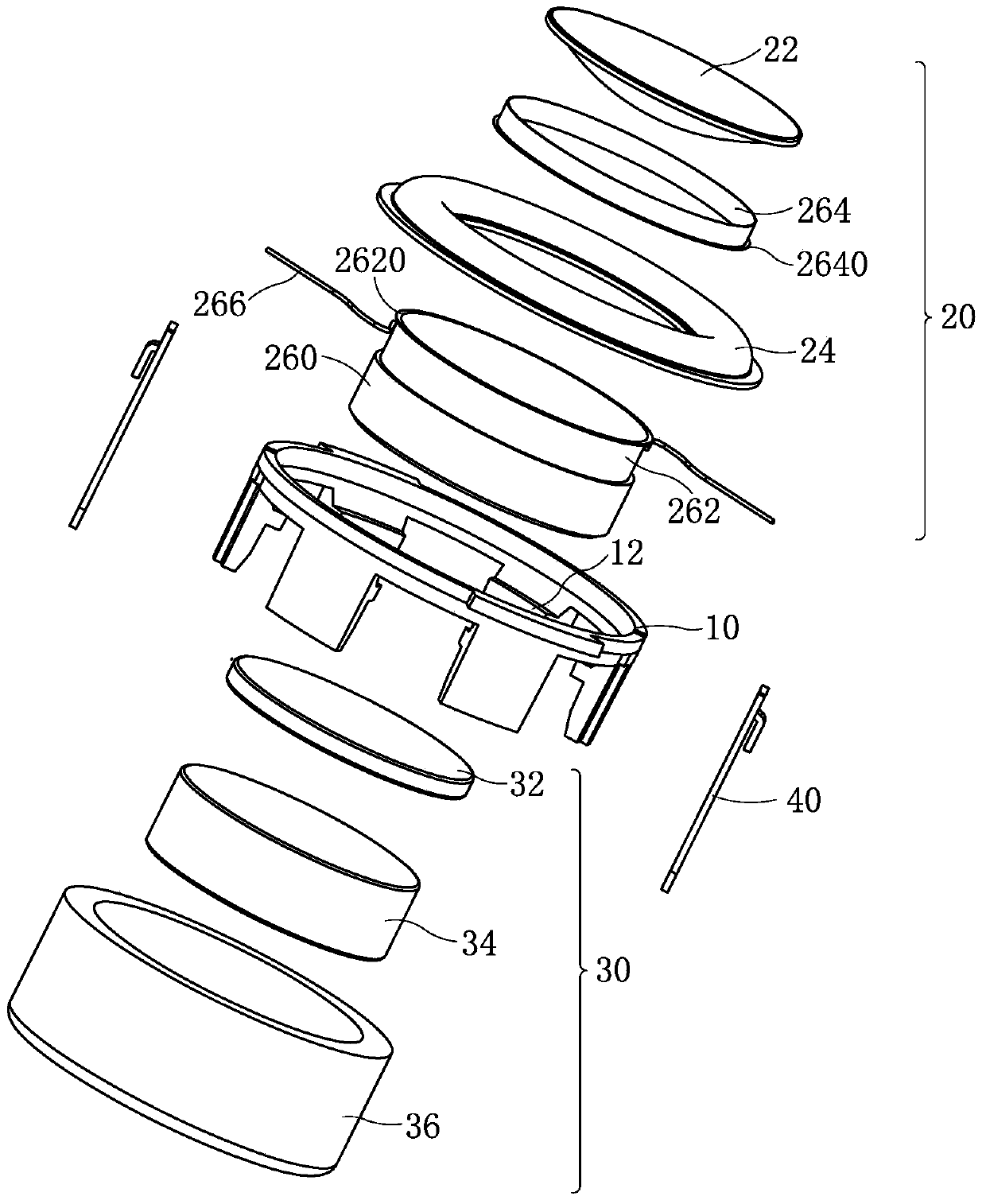

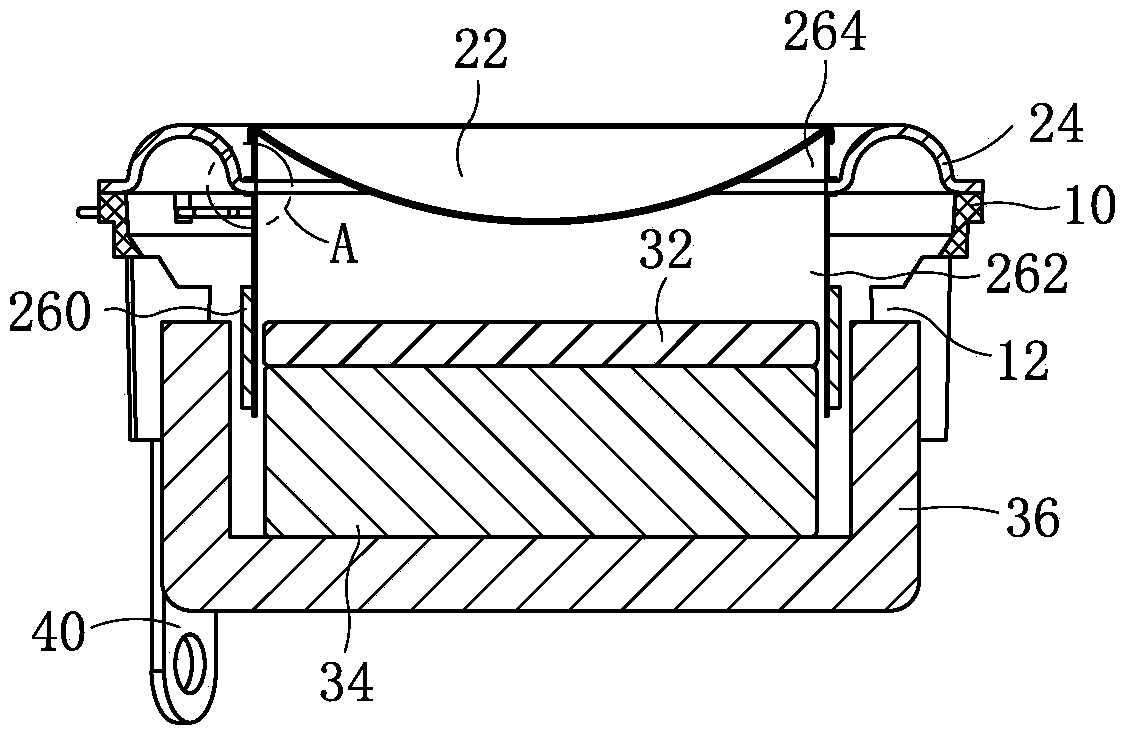

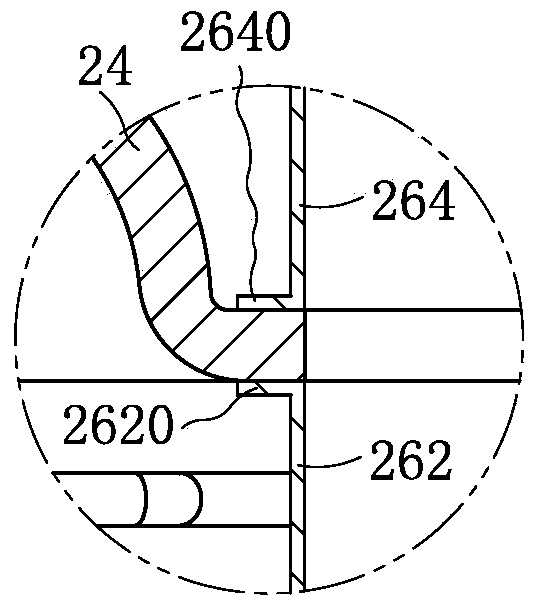

speaker

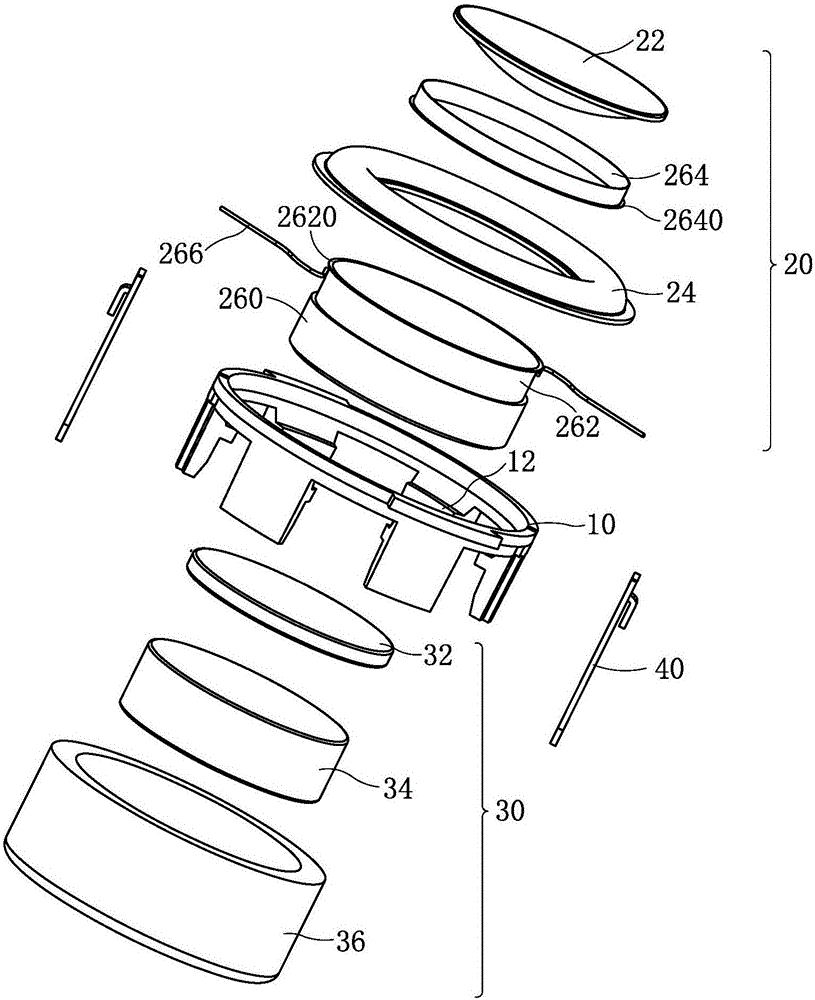

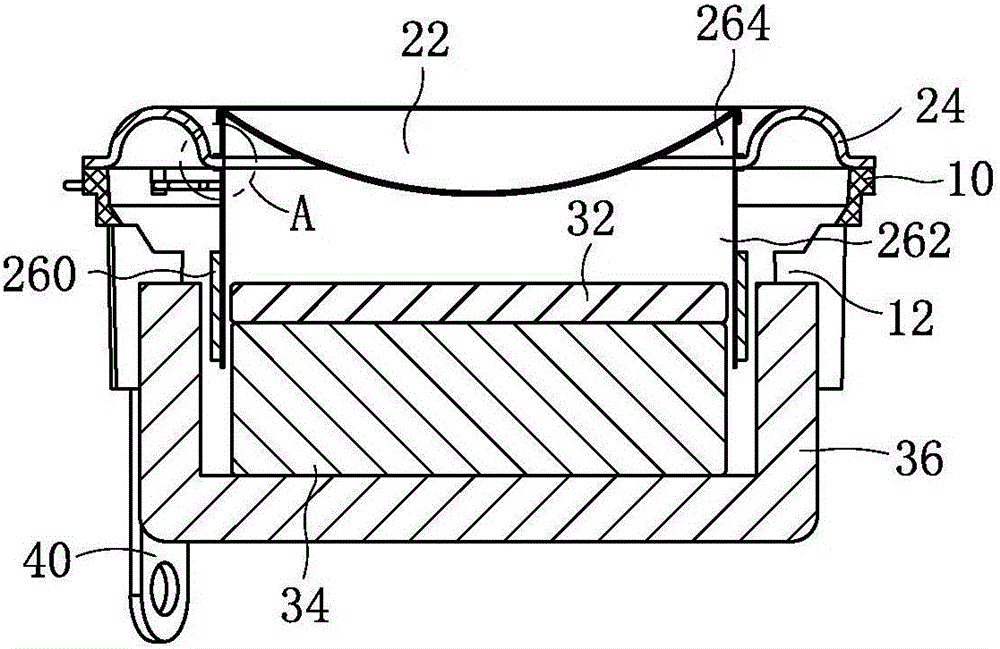

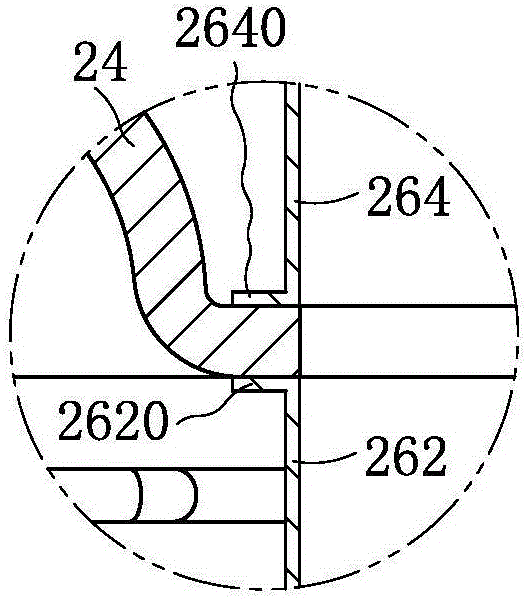

ActiveCN105959879BIncrease the vibration spaceEnsure consistencyElectrical transducersSound qualityEngineering

The present invention discloses a loudspeaker, and relates to the electro acoustical product technology field. The loudspeaker comprises a shell in which a vibration system and a magnetic circuit system are accommodated, and the vibration system comprises a voice coil, a folding ring fixed on the skeleton of the voice coil and a DOME. The skeleton comprises a first skeleton and a second skeleton which are spliced together up and down, and the inner edge of the folding ring is fixed between the first and second skeletons. The loudspeaker of the present invention solves the technical problems in the prior art that the adhesion consistency of the folding ring of the loudspeaker is poor, the acoustic performance is poor, etc., and is good in product consistency and sound quality, high in acoustic performance, production efficiency and reliability and long in service life.

Owner:GOERTEK INC

Laser structures and methods for slot bonding of iii-v/silicon materials

ActiveCN111262132BImprove transmittanceReduce local feverOptical wave guidanceLaser detailsTransmittanceThin membrane

The invention discloses a laser structure and method for slotting and bonding III-V group / silicon materials, and relates to the field of structural design of hybrid lasers. The method comprises: preparing a ridge waveguide structure; manufacturing a groove-type III-V group laser Embedding the ridge waveguide structure in the groove of the III-V laser for alignment and bonding, forming an evanescent wave coupling structure after bonding, and the laser light is coupled out from the SOI waveguide port. The invention adopts the groove structure laser and the silicon-based device to couple, and adopts the groove-type embedded structure in the longitudinal direction, which limits the offset distance of the silicon-based transmission device in space from the lateral direction, increases the bonding strength, and at the same time The difficulty of bonding is reduced; in addition, the present invention uses ZnO transparent conductive film to assist bonding hybrid laser, ZnO has good transmittance and can form a low-resistance conductive layer after a high-temperature film.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

Loudspeaker

ActiveCN105959879AIncrease the vibration spaceEnsure consistencyElectrical transducersSound qualityEngineering

The present invention discloses a loudspeaker, and relates to the electro acoustical product technology field. The loudspeaker comprises a shell in which a vibration system and a magnetic circuit system are accommodated, and the vibration system comprises a voice coil, a folding ring fixed on the skeleton of the voice coil and a DOME. The skeleton comprises a first skeleton and a second skeleton which are spliced together up and down, and the inner edge of the folding ring is fixed between the first and second skeletons. The loudspeaker of the present invention solves the technical problems in the prior art that the adhesion consistency of the folding ring of the loudspeaker is poor, the acoustic performance is poor, etc., and is good in product consistency and sound quality, high in acoustic performance, production efficiency and reliability and long in service life.

Owner:GOERTEK INC

Comb-shaped stereo silicon processing micro mechanical structure with fixed tooth offset

InactiveCN1138148CSingle block bonding area is largeIncrease bonding areaAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesCapacitanceElectrical resistance and conductance

Owner:TSINGHUA UNIV

Aluminum foil with graphene for lithium battery and preparation method of aluminum foil

ActiveCN112467145AUniform solution concentrationMild responseElectrode carriers/collectorsLi-accumulatorsManganese oxideGraphite

The invention discloses an aluminum foil with graphene for a lithium battery and a preparation method of the aluminum foil, which relate to the field of lithium battery positive electrode materials. The method comprises the following steps of immersing the aluminum foil in a corrosive agent, electrifying to corrode, putting a porous aluminum foil substrate into plasma vapor deposition equipment, vacuumizing, heating to the temperature of 980-1000 DEG C of theporous aluminum foil substrate, introducing inert gas mixed with methane to obtain a graphene aluminum foil, splashing silver ions on thesurface of the graphene aluminum foil to obtain a silver-coated graphene aluminum foil, dissolving organic lithium, organic cobalt and organic manganese in a chitin solution to obtain a reaction solution, calcining the reaction solution in an inert gas environment with the temperature of 900-1000 DEG C for 1-2 hours, and naturally cooling to obtain carbon-coated lithium, cobalt and manganese oxides. The carbon is of a porous structure, and the silver-coated graphene aluminum foil is coated with the porous carbon after the porous carbon is mixed with an adhesive. Active substances can be prevented from falling off, and the service life of the battery is prolonged.

Owner:NOZO GRP CO LTD

Coating method of lost foam

InactiveCN109926551ALow Modular Cluster WeightLight cluster weightMoulding toolsFoundry mouldsEnergy consumptionCoating

The invention discloses a coating method of lost foam. The coating method includes the following steps that multiple foam mold parts are bonded and combined into a casting single body, and first adhesive tape is pasted on first bonding planes of the casting single body; second adhesive tape is pasted on second bonding planes of an inner runner; the casting single body and a runner assembly in thesecond step are subjected to immersion coating; the casting single body and the runner assembly which are subjected to coating are taken out and dried; the first adhesive tape and the second adhesivetape are torn down, the first bonding planes and the second bonding planes are glued, and assembly of the casting single body and the runner assembly is completed; supplementary paint brushing is conducted on non-bonded areas in the first bonding planes and the second bonding planes, and a product is obtained after drying. Compared with an existing coating method of the lost foam, the coating method has the beneficial effects of being low in labor cost, small in energy consumption and short in consumed time.

Owner:安徽南凯元机械有限公司

Structure of silicon-based metal intermediate layer compound semiconductor wafer and preparation method thereof

InactiveCN110739285AReduce thermal stressImprove and improve the production processSemiconductor/solid-state device detailsSolid-state devicesWaferPhysical chemistry

The invention discloses a structure of a silicon-based metal intermediate layer compound semiconductor wafer and a preparation method thereof. The structure sequentially comprises a compound semiconductor wafer, a metal layer M1, a metal layer M2 and a silicon wafer from top to bottom. The preparation method of the structure comprises the following steps: depositing a sacrificial layer on the compound semiconductor wafer; injecting ions into the compound semiconductor wafer through the sacrificial layer; polishing the sacrificial layer after the injection is completed and removing or partiallyremoving the sacrificial layer; evaporating the metal layer M1 on the compound semiconductor wafer or the remaining sacrificial layer on the compound semiconductor wafer; cleaning and drying the silicon wafer; evaporating the metal layer M2 on the silicon wafer; bonding the metal layer M1 on the compound semiconductor wafer and the metal layer M2 on the silicon wafer; and annealing the compositewafer after completion of bonding and stripping at the ion injection position to obtain the excess compound semiconductor wafer.

Owner:BEIJING UNIV OF TECH

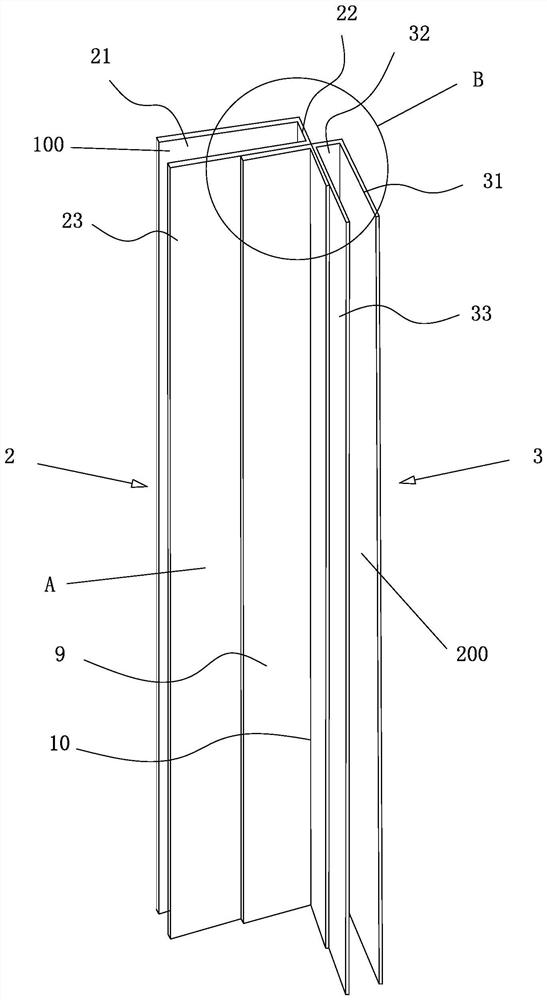

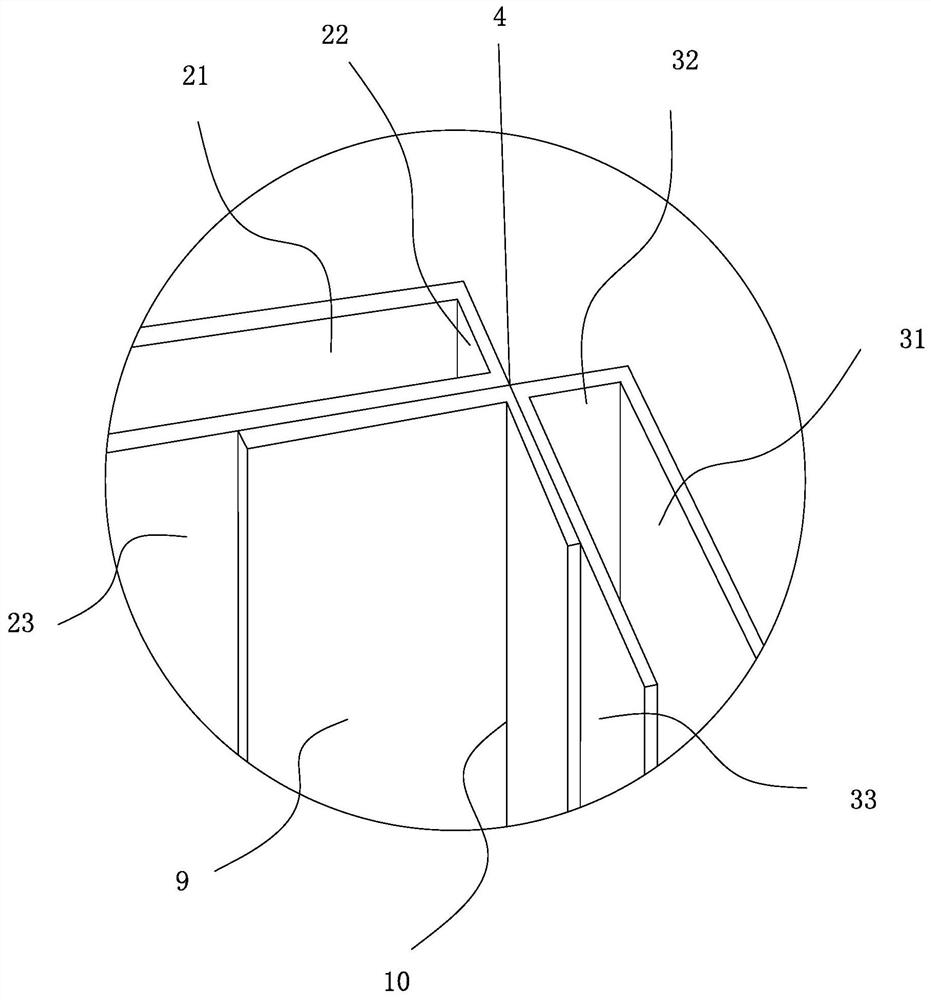

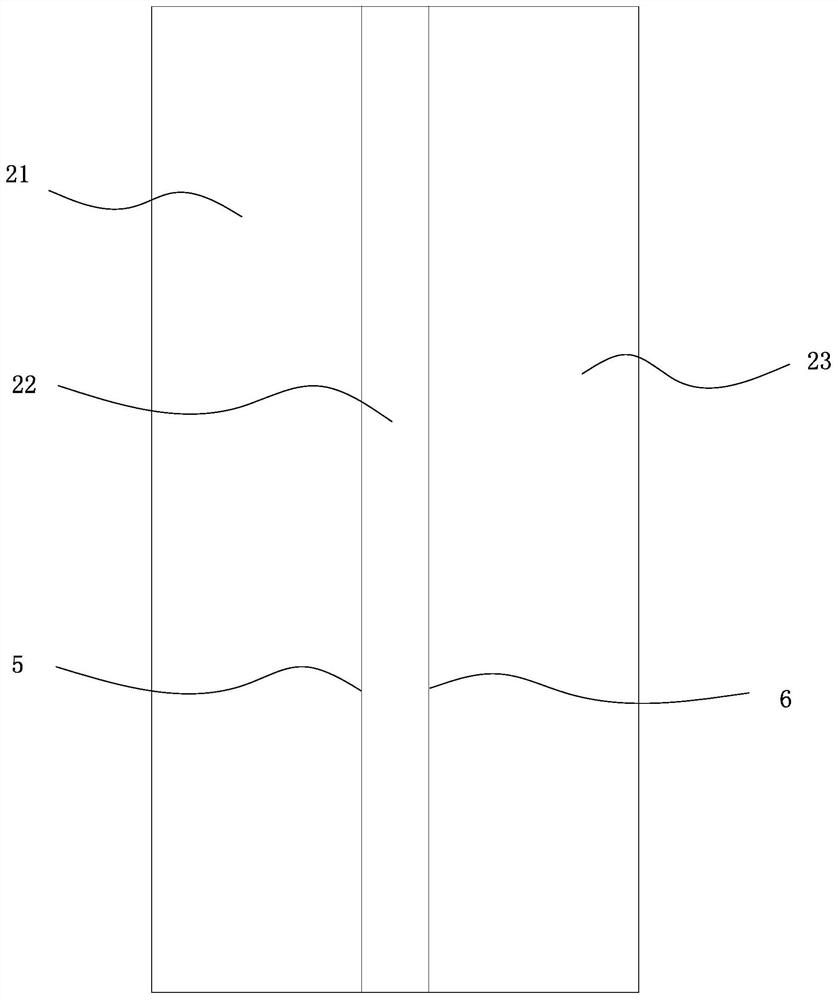

Novel connection device for right-angle turn of thick board

The invention relates to the field of packaging, in particular to a novel connection device for the right-angle turn of a thick board. The problem of high difficulty in connection between a connectingdevice and the thick board in the prior art is solved mainly, and the novel connection device comprises a first angle bead connecting piece and a second angle bead connecting piece which are wrappedon the parts, close to each other, of two adjacent thick boards separately; the contact areas or the areas, close to each other, on the first angle bead connecting piece and the second angle bead connecting piece are connected through adhesive or sewing or connecting pieces, and the connection area forms a rotating shaft, so that the two thick boards are rotated along the rotating shaft separately, and the sides, located on the same side as the rotating shaft, of the first angle bead connecting piece and the second angle bead connecting piece are defined as the inner side faces; and connectingplates are connected with the inner side faces of the first angle bead connecting piece and the second angle bead connecting piece through adhesive, and first bent lines are arranged at the positions, located on the rotating shaft, of the connecting plates.

Owner:林照民

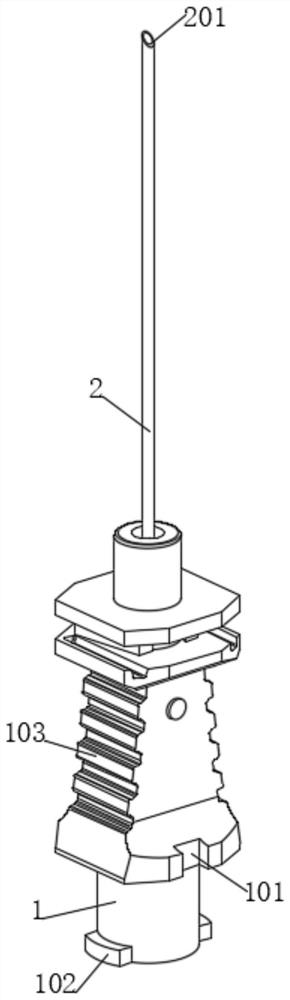

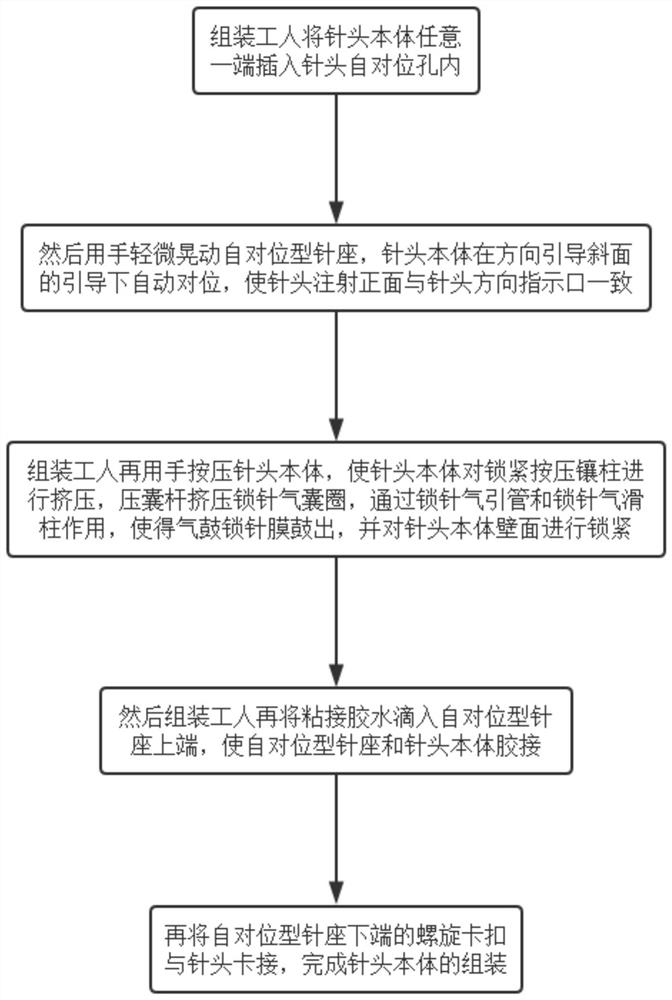

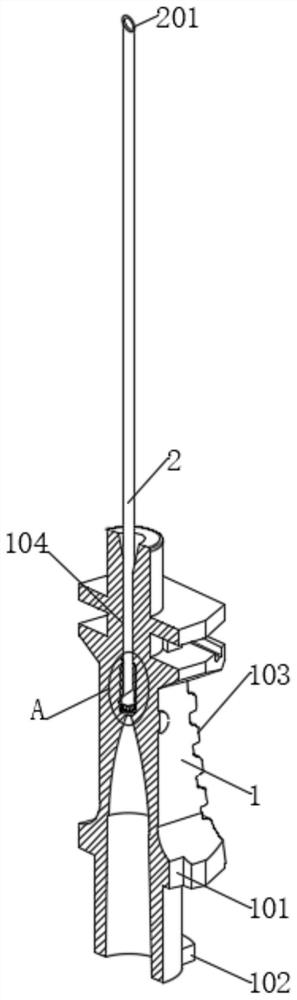

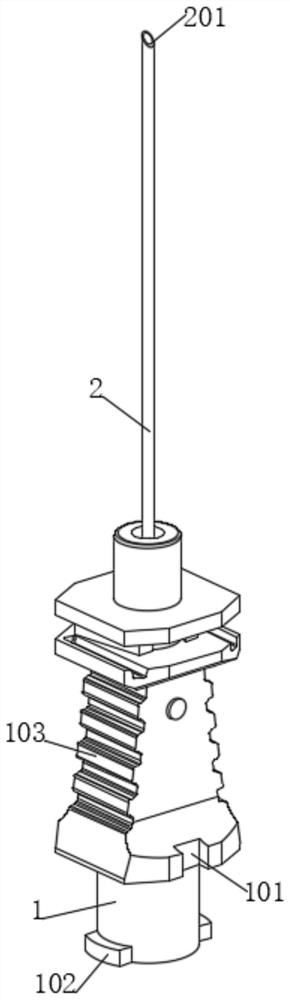

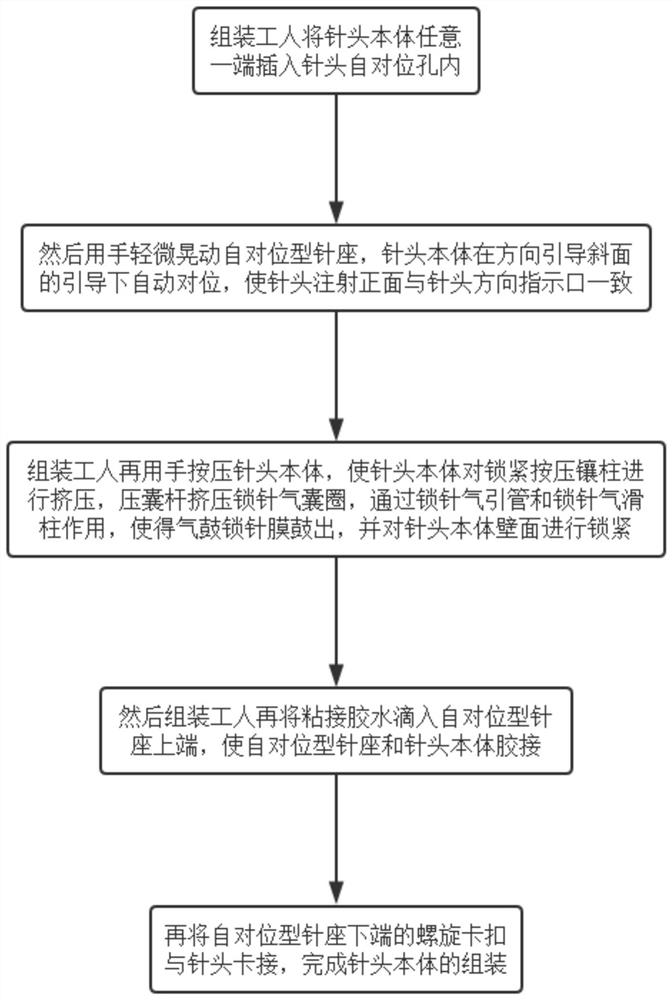

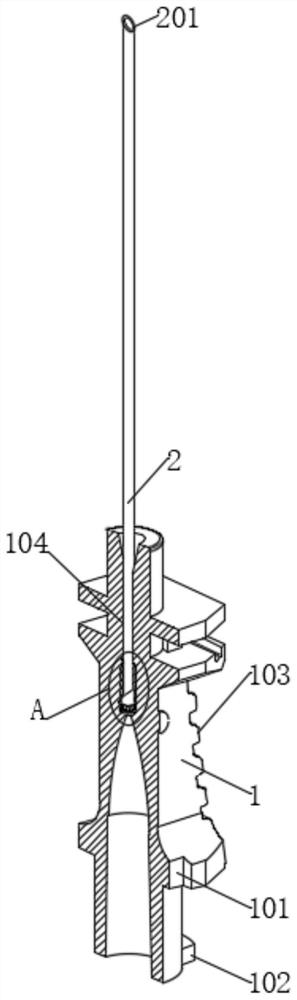

A self-aligning needle seat

ActiveCN113577461BReduce the difficulty of bondingImprove bonding qualityInfusion needlesSpinal anesthesiaPhysical medicine and rehabilitation

The invention discloses a self-alignment needle seat and its use method, belonging to the field of medical appliances. The invention is suitable for anesthesia needles, especially spinal anesthesia needles, including self-alignment needle seats and self-alignment needles The needle body in the seat, both ends of the needle body are provided with needle injection fronts inclined in the same direction, through the cooperation of the direction guide slope and the needle direction indicator port, the needle body can be effectively aligned independently, and the assembly worker can assist the assembly worker to judge the needle The front side of the injection position, thereby eliminating the need for assembly workers to identify the front side of the needle injection with the naked eye, reducing manpower input, reducing production costs, improving production efficiency, and improving the economic benefits of medical device manufacturers, and through locking The cooperation of the pressing column and the locking needle airbag ring can fix the needle body after the alignment is completed, reduce the difficulty of subsequent bonding of the needle body, and improve the functionality of the self-alignment needle holder.

Owner:福建银海万向医用科技有限公司

Touch panels and the driving method thereof

ActiveUS9798404B2Reduce difficultyImprove performanceStatic indicating devicesNon-linear opticsCapacitanceManufacturing technology

A touch panel and a driving method are described in the present disclosure. A driving chip is arranged within a chip area of a non-display area. The driving chip includes a plurality of pins. At least a portion of the pins outputs first driving signals for controlling the pixel electrodes, and outputs second driving signals for controlling the touch sensor. A plurality of wirings corresponding to the pins is arranged within the fan area, and the wirings transmit the first driving signals and the second driving signals outputted by the pins. In view of the above, the difficulties of the bonding manufacturing process are reduced. At the same time, the coupling capacitance between the wirings is reduced, and thus the display performance and the touch sensibility of the touch panel 10 are enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

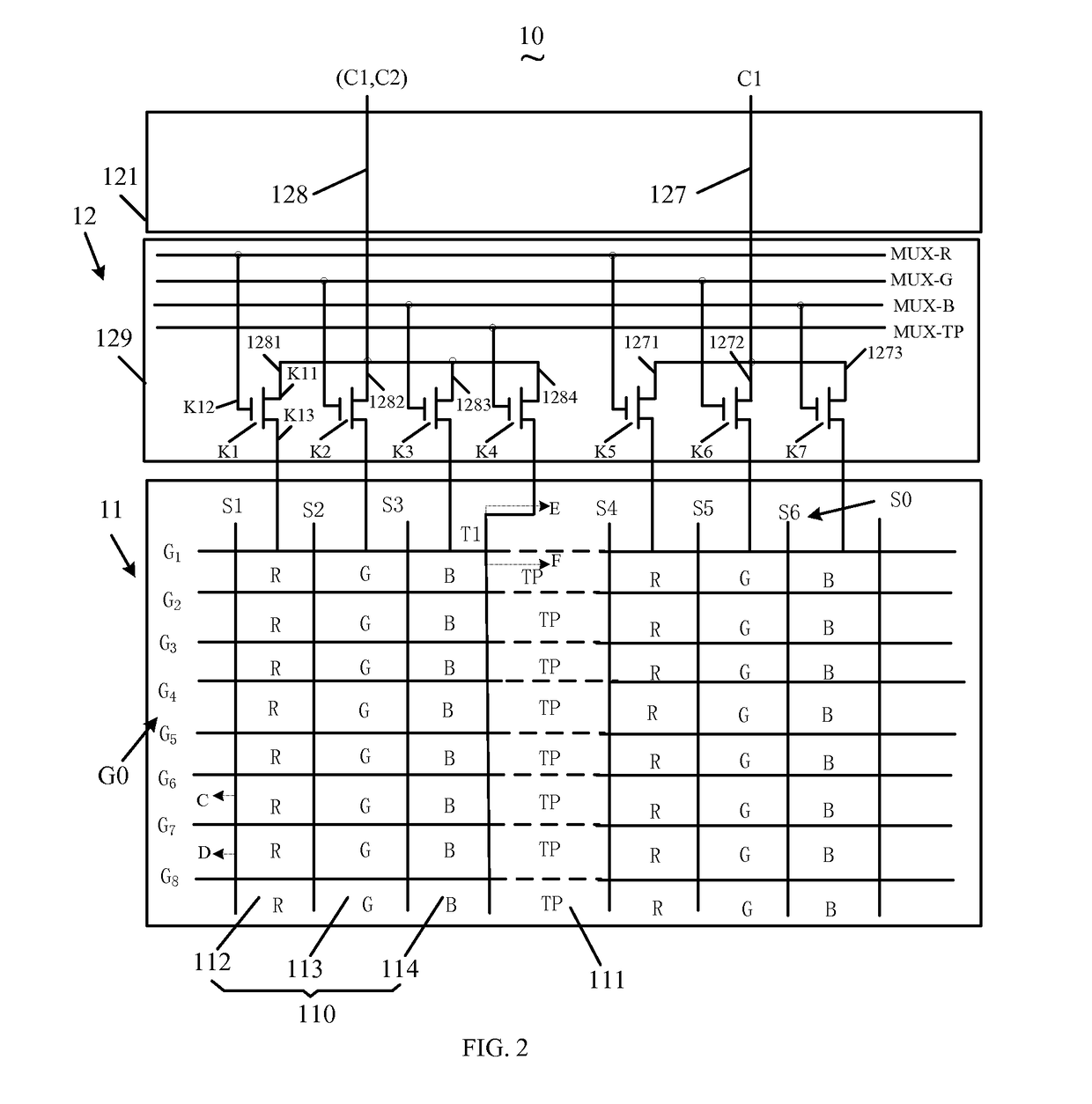

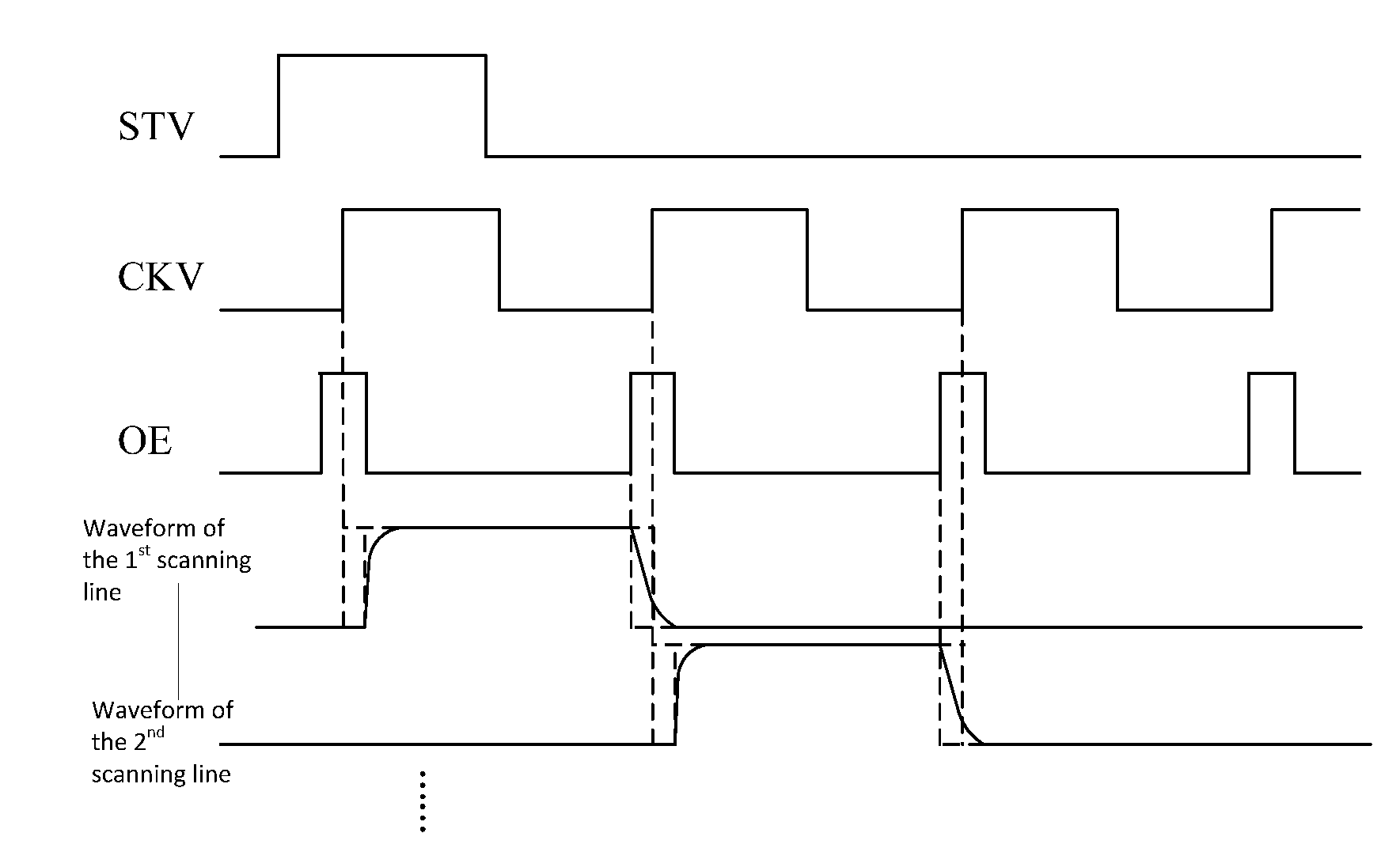

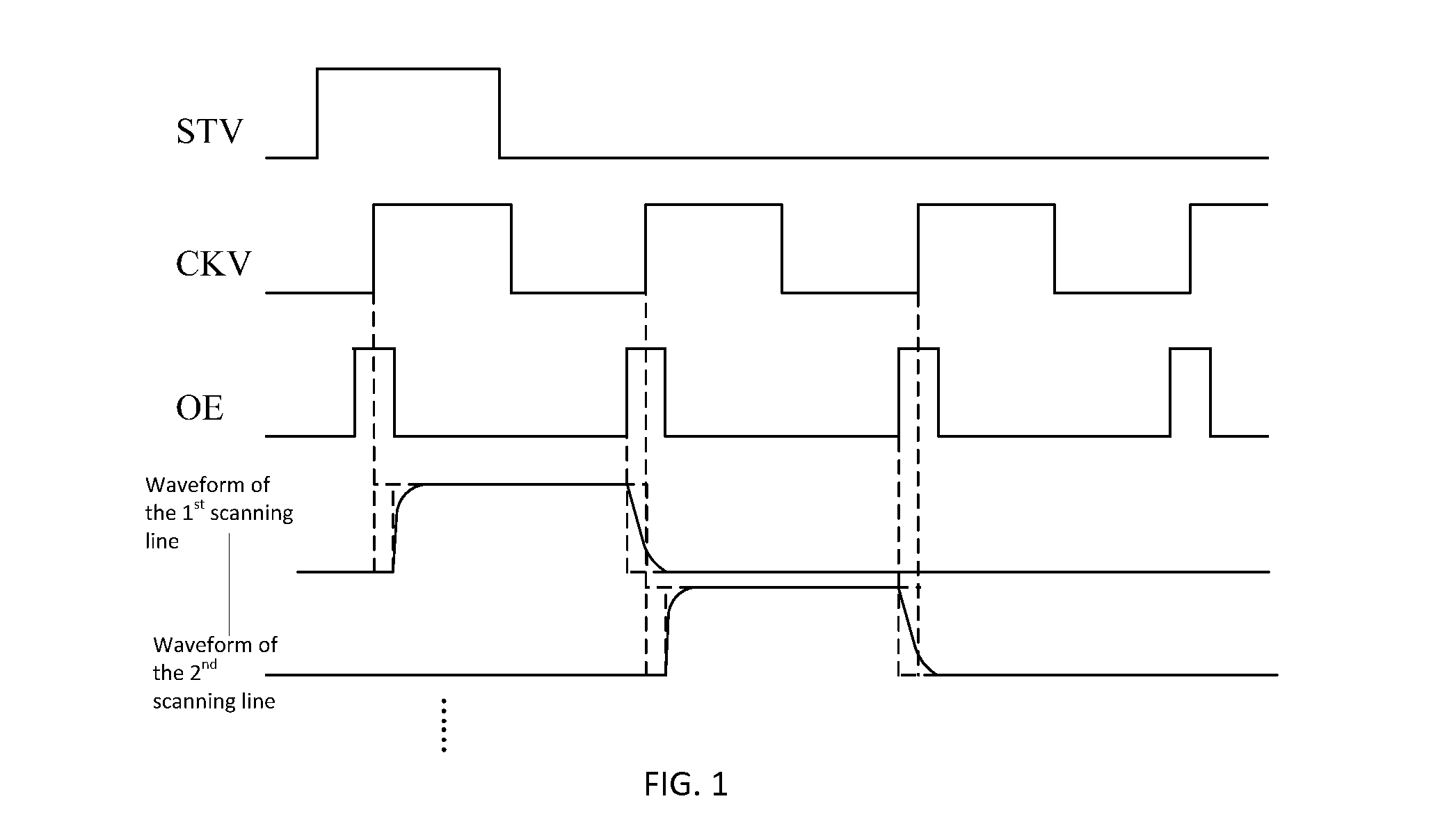

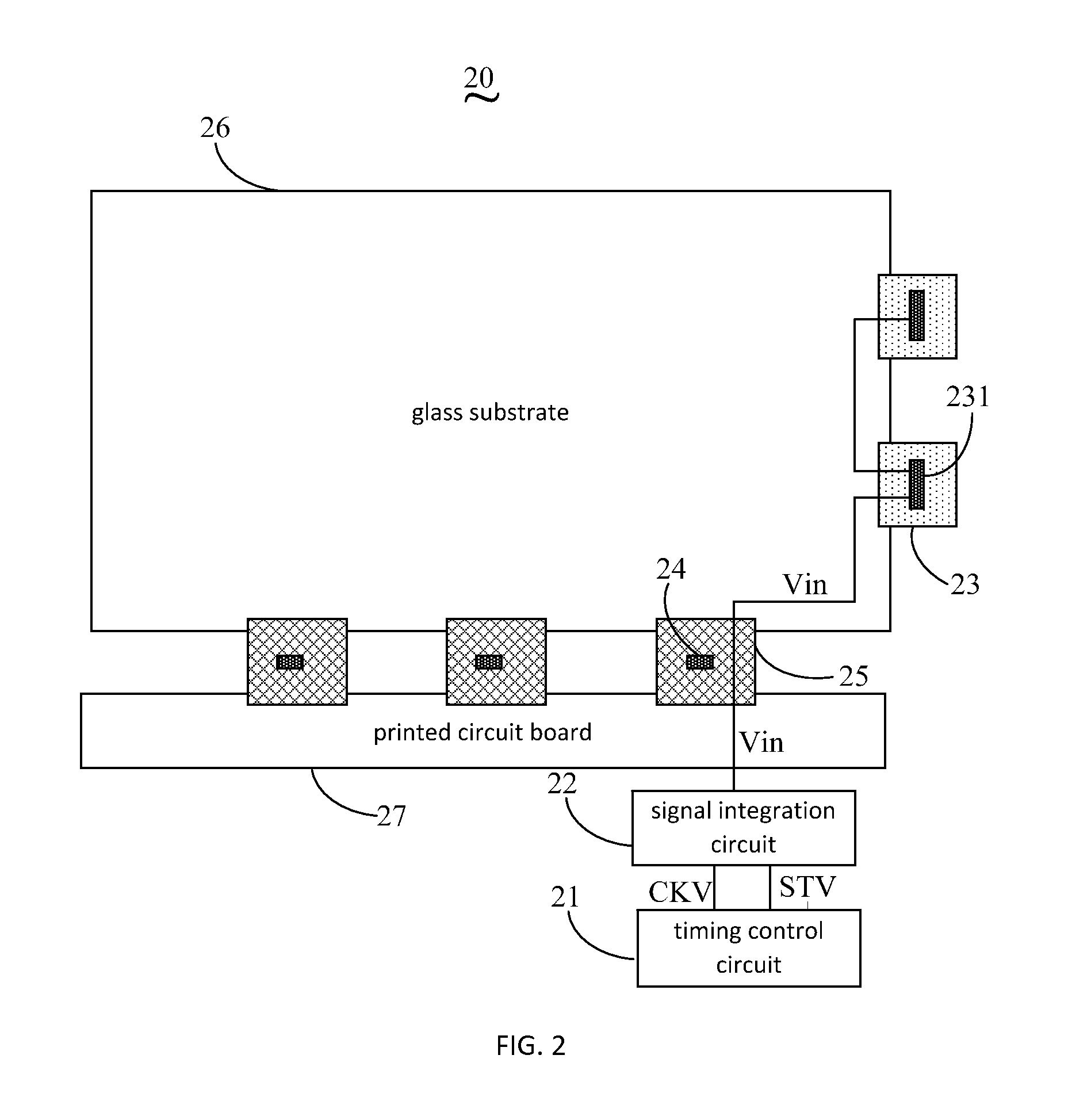

Active matrix display, scanning driven circuit and the method thereof

InactiveUS20140375614A1Reduce in quantityGapCathode-ray tube indicatorsInput/output processes for data processingVoltage pulseActive matrix

An active matrix display, and the scanning driven circuit and the scanning driven method thereof are disclosed. The scanning driven circuit includes a delaying module. An input end of the delaying module receives input signals integrated by initial clock voltage pulse (CKV) signals and start voltage pulse (STV) signals. The input signals are delayed by a first delayed portion and a second delayed portion such that a first output of the delaying module outputs output enable (OE) signals and a second output of the delaying module outputs the delayed CKV signals. In this way, the number of the transmission lines is decreased, and the number of the output pins of the timing control chips and that of the input pins of the scanning driven chips are also decreased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

A bracket positioning device

Owner:THE SECOND PEOPLES HOSPITAL OF SHENZHEN

Self-alignment type needle seat and use method thereof

ActiveCN113577461AReduce the difficulty of bondingImprove bonding qualityInfusion needlesPhysical medicine and rehabilitationAnesthesia needle

The invention discloses a self-alignment type needle seat and a use method thereof, belongs to the field of medical appliances, and is suitable for anesthetic needles, in particular to spinal anesthetic needles. The self-alignment type needle seat comprises a self-alignment type needle seat body and a needle head body installed in the self-alignment type needle seat body, and needle head injection front faces inclined in the same direction are arranged at the two ends of the needle head body; through the cooperation of the direction guiding inclined plane and the needle direction indicating port, the needle body can be effectively and autonomously aligned, an assembling worker is assisted to judge the injection front face position of the needle, the step that the assembling worker recognizes the injection front face of the needle with naked eyes is omitted, manpower input is reduced, the production cost is reduced, and the production efficiency is improved; according to the self-alignment type needle seat, the self-alignment type needle seat is simple in structure and convenient to use, the economic benefit of a medical instrument manufacturer is improved, the aligned needle head body can be fixed through cooperation of the locking and pressing embedded column and the needle locking air bag ring, the follow-up bonding difficulty of the needle head body is reduced, and the functionality of the self-alignment type needle seat is improved.

Owner:福建银海万向医用科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com