Comb teeth type body silicon working microchemical accelerometer

An accelerometer and micro-mechanical technology, applied in the direction of measuring acceleration, velocity/acceleration/shock measurement, measuring device, etc., can solve the problems of increasing mass, thickening of sensitive mass movable piece, small bonding surface, etc., to achieve resolution And the effect of improving the accuracy, reducing the number of lead outputs, and reducing the bonding contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

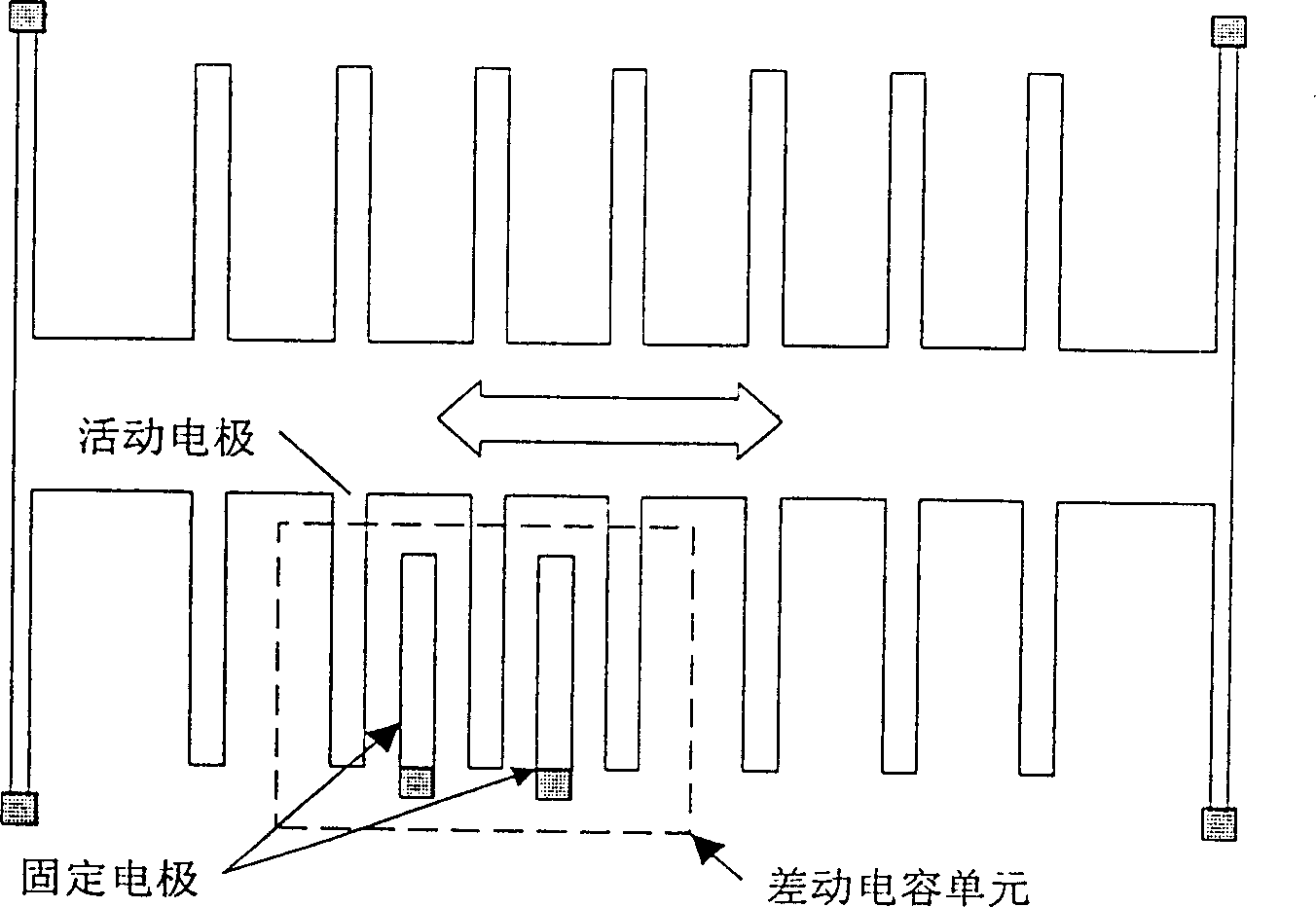

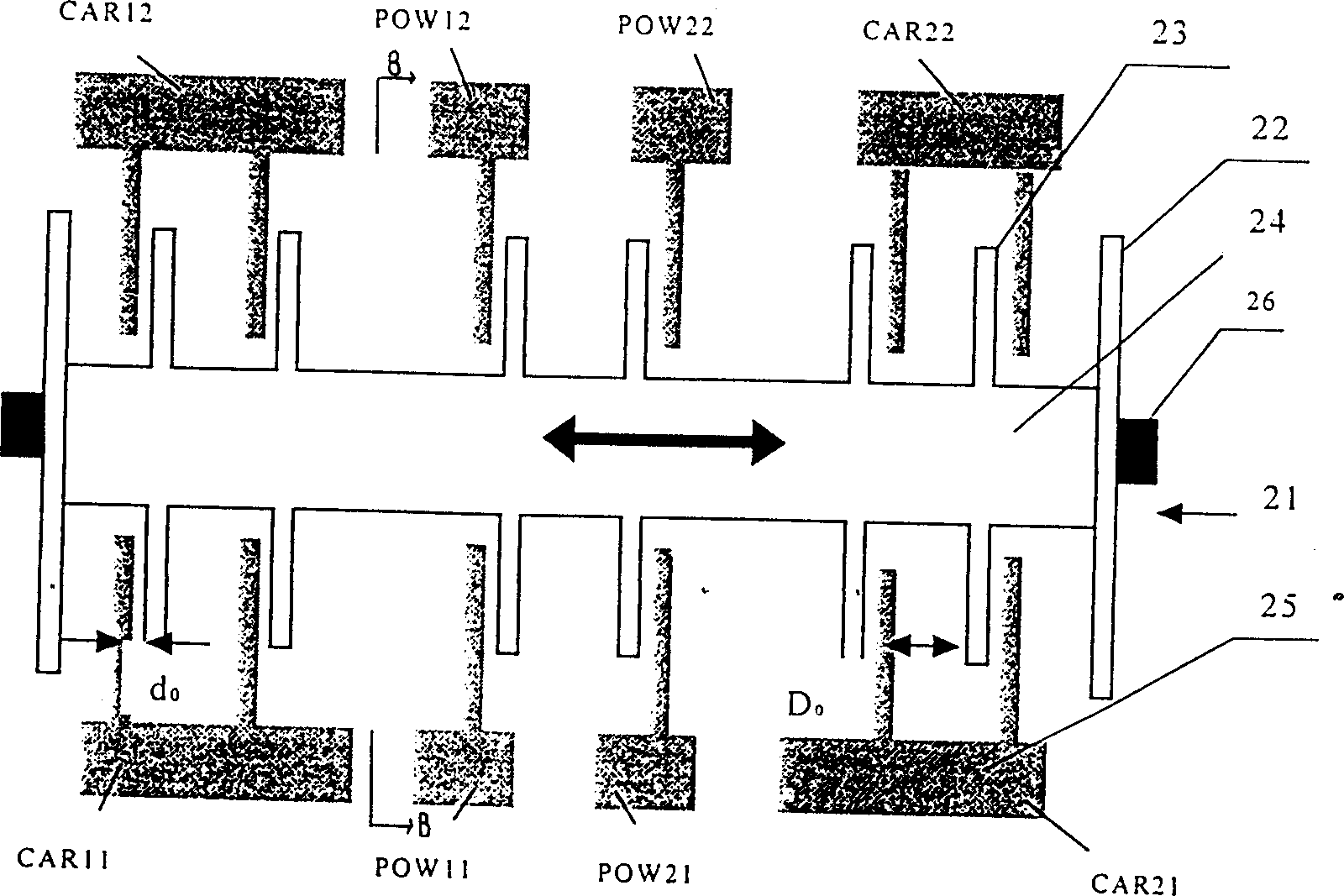

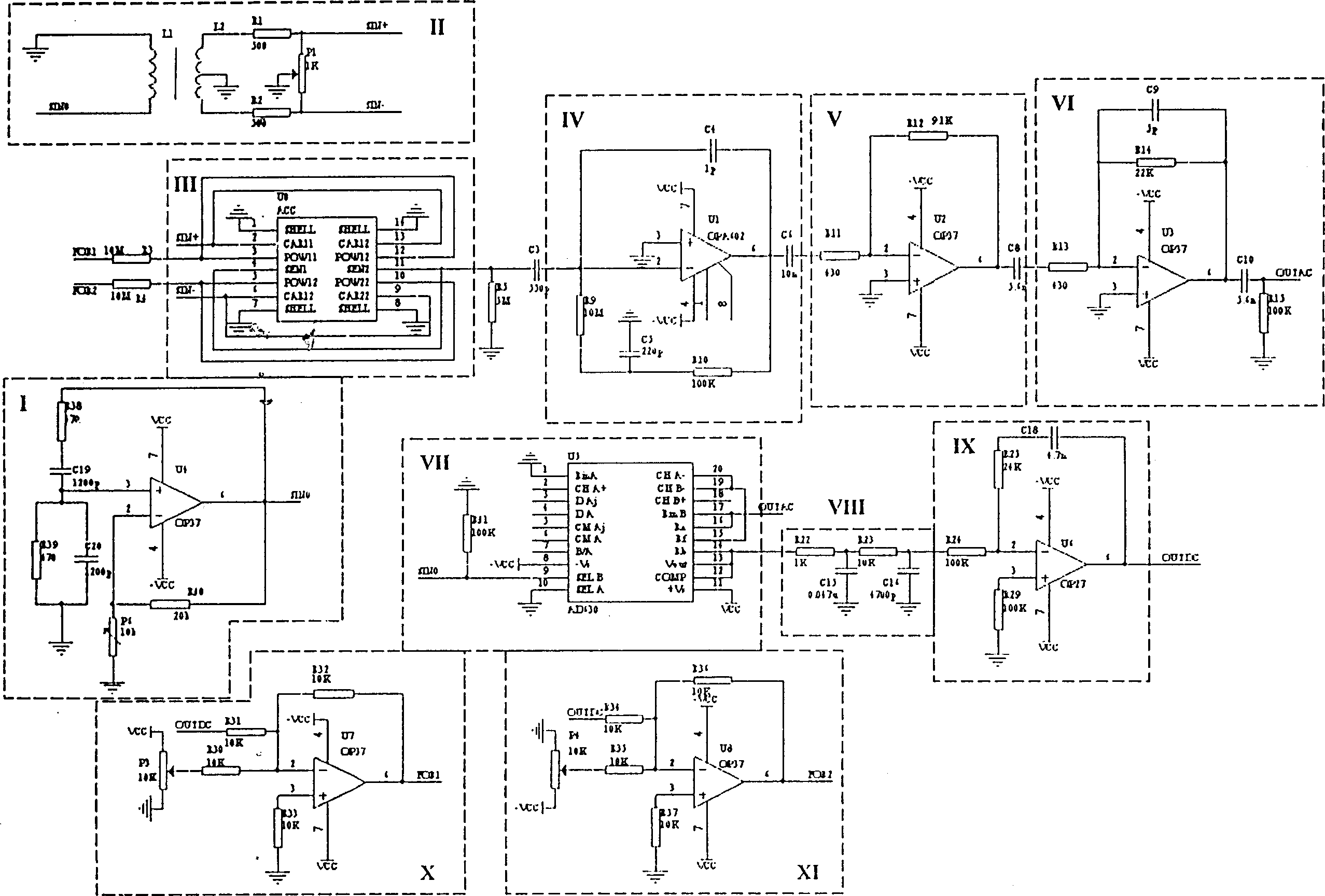

[0018] Embodiments of the Invention Comb-tooth Bulk Silicon Machining Micromachined Accelerometer (see figure 2 , 4 ). Including: a sensitive mass element 21 composed of a tooth hub 24, multiple groups of movable teeth 23 and folding beams 22, a fixed tooth 25 and a substrate 27; the movable teeth 23 protrude from the tooth hub 24 to form a double-sided comb Tooth structure, the folding beams 22 at both ends of the tooth hub are fixed on the substrate 27 through the column 26, so that the tooth hub and multiple groups of movable teeth are suspended and parallel to the substrate; the fixed teeth 25 are multiple groups directly fixed on the substrate. Single-sided comb-tooth structure; each movable tooth of the sensitive mass element is a movable electrode of the variable capacitor, which is arranged alternately with each comb of the fixed teeth to form a differential capacitor as a whole; this embodiment is different from the existing The difference of the comb tooth surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com