A self-aligning needle seat

An alignment type, needle seat technology, applied in the field of medical equipment, can solve the problems of reducing the economic benefits of medical equipment manufacturers, reducing production efficiency, increasing production costs, etc., to reduce human input, improve production efficiency, and improve functionality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

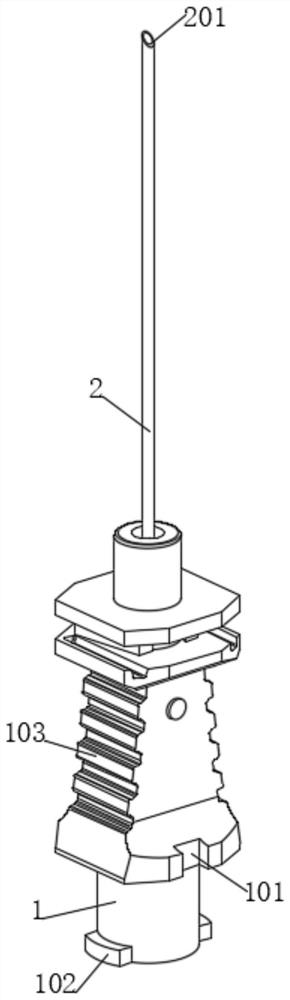

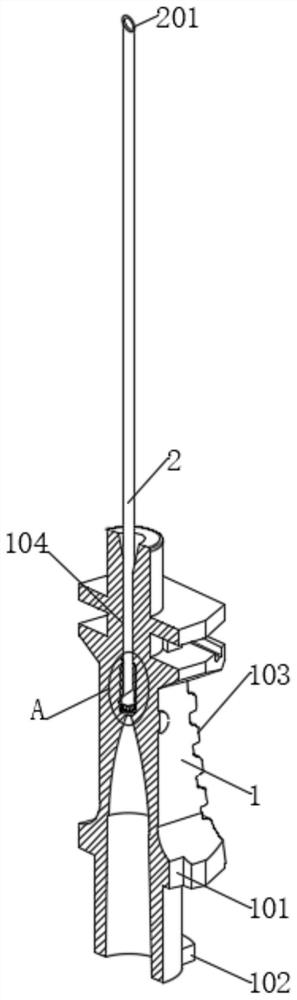

[0053] see Figure 1-11 , a self-alignment needle holder, comprising a self-alignment needle holder 1 and a needle body 2 installed in the self-alignment needle holder 1, both ends of the needle body 2 are provided with needle injection fronts inclined in the same direction 201, see figure 1 and image 3 , the left and right ends of the self-alignment needle holder 1 are fixedly connected with a plurality of cylindrical friction strips 103 , and the lower end of the self-alignment needle holder 1 is fixedly connected with a plurality of screw buckles 102 . The cylindrical friction strip 103 increases the friction between the self-alignment needle holder 1 and the assembly worker's fingers, which is convenient for the assembler to hold the self-alignment needle holder 1, improves the practicability of the self-alignment needle holder 1, and the spiral The buckle 102 can increase the connection strength between the self-alignment needle base 1 and the syringe, effectively prev...

Embodiment 2

[0057] see Figure 1-11 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 7 and Figure 10 , the outer end of the telescopic support sleeve 7 is fixedly connected with a plurality of magnetic particle columns 701, and the magnetic poles carried by the magnetic particle columns 701 on the upper and lower sides are opposite magnetic poles. When the telescopic support sleeves 7 on the upper and lower sides are close to each other, the magnetic particle column 701 generates a mutual magnetic force, which makes the telescopic support sleeve 7 elongate, increases the pressing force between the flexible locking suction cups 8, and then improves the adsorption of the flexible locking suction cups 8 Strength, increased lockin...

Embodiment 3

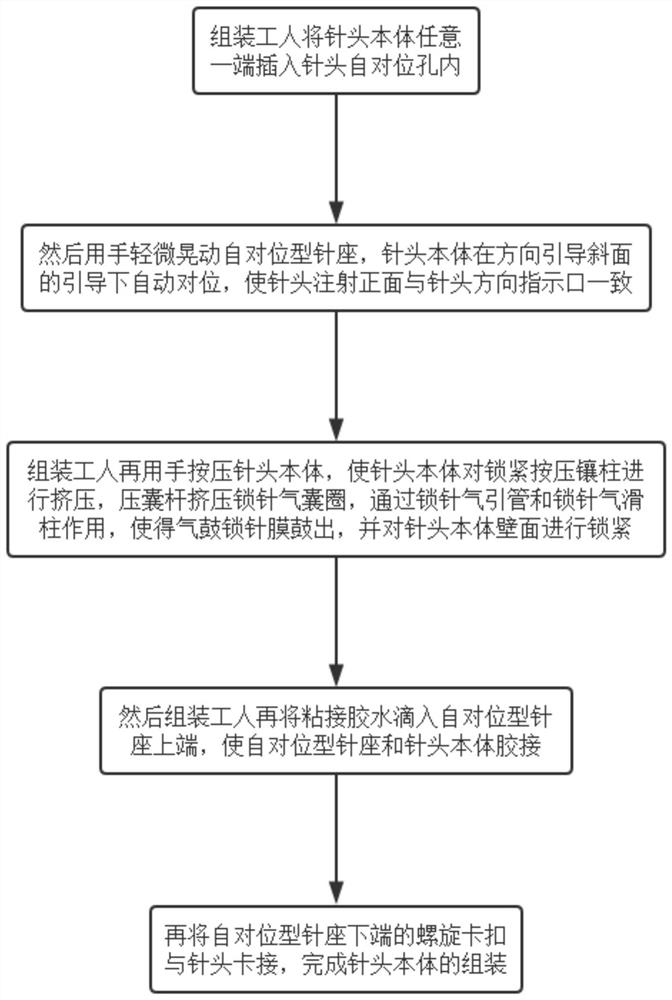

[0059] see Figure 1-11 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to figure 2 , a method for using a self-alignment needle seat, comprising the following steps:

[0060] S1. The assembler inserts any end of the needle body 2 into the self-alignment hole 104 of the needle;

[0061] S2. Then shake the self-aligning needle seat 1 slightly by hand, and the needle body 2 will be automatically aligned under the guidance of the direction guiding slope 301, so that the injection front 201 of the needle is consistent with the needle direction indicating port 101;

[0062] S3. The assembler then presses the needle body 2 by hand, so that the needle body 2 squeezes the locking and pressing column 3, and the pressure bag lever 6 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com