Bonding fixture of flexible gyroscopic moment skeleton coil

A skeleton coil and gyro torque technology, applied in the direction of connecting components, manufacturing tools, workpiece clamping devices, etc., can solve the problems of high technical difficulty, only 20% product qualification rate, and long processing cycle, so as to improve the product qualification rate, The effect of shortening the processing cycle and reducing the difficulty of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

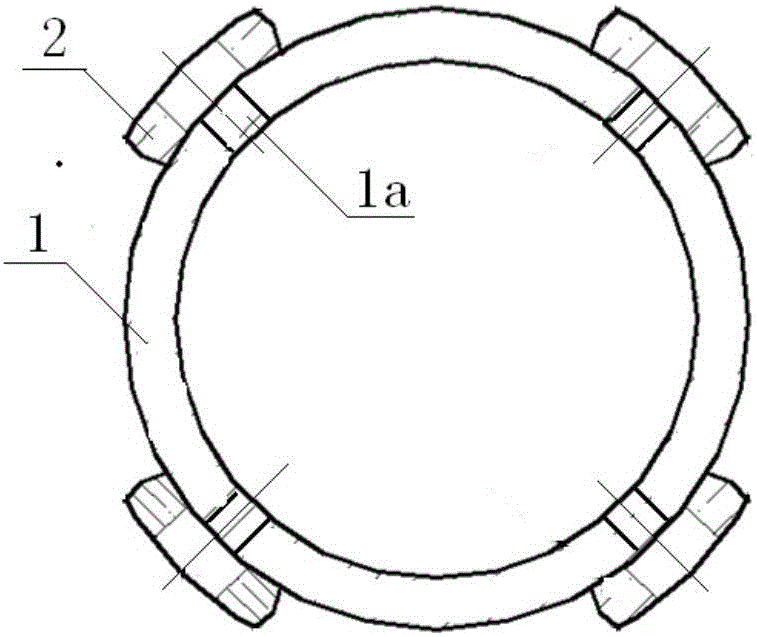

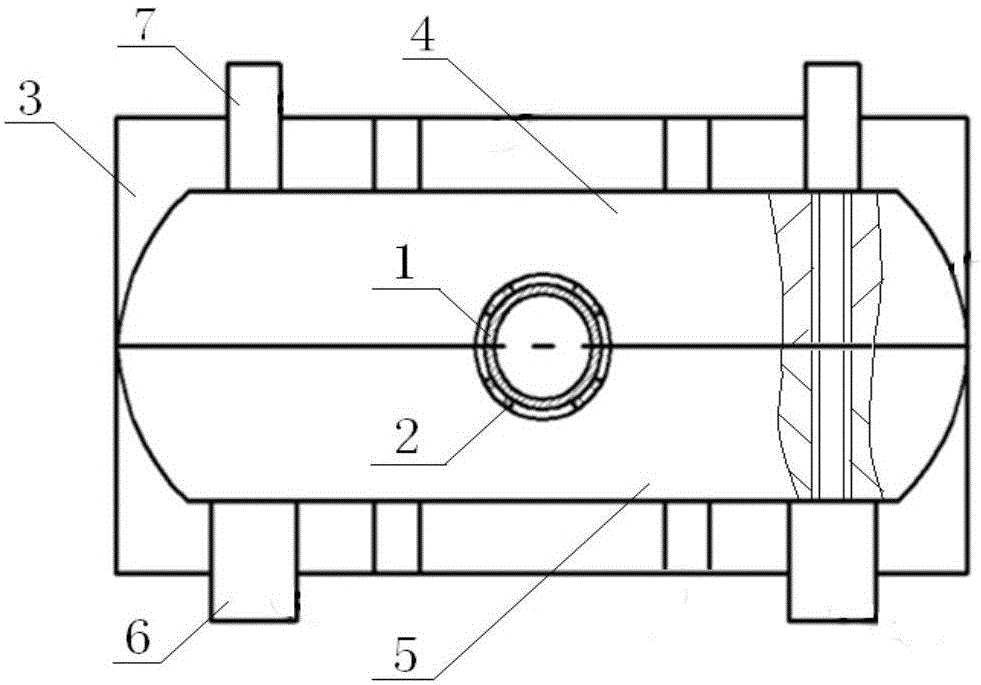

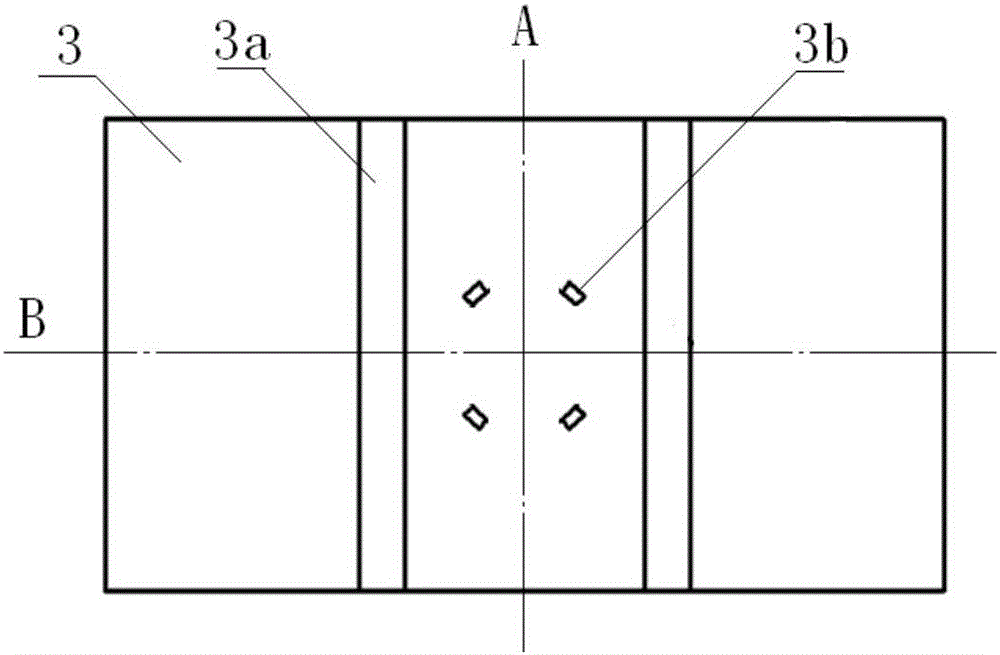

[0010] The present invention will be described in further detail below. see Figure 1 to Figure 4 , the bonding fixture of the flexible gyro torque frame coil, the moment frame 1 to be bonded is a round tube, and there are four rectangular positioning grooves 1a uniformly distributed along the circumference on one end surface of the moment frame 1, and the moment frame 1 Four torque coils 2 are uniformly bonded along the circumference of the outer cylindrical surface. The torque coil 2 is an elongated coil extending along the axis of the torque frame 1. The four rectangular positioning slots 1a correspond to the four torque coils 2 one by one. The longitudinal bisector of the torque coil 2 of the 1 axis is coplanar with the longitudinal bisector of the rectangular positioning groove 1a of the corresponding torque frame 1 axis; it is characterized in that: the bonding fixture consists of a base 3, an upper splint 4, a lower splint 5 and Composed of 2 clamping bolt pairs; the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com