Laser structures and methods for slot bonding of iii-v/silicon materials

A III-V, laser technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of inability to make light-emitting devices, unsuitable for integrated chip light source devices, etc., and achieve easy decomposition, reduce manufacturing processes, and simplify processes effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

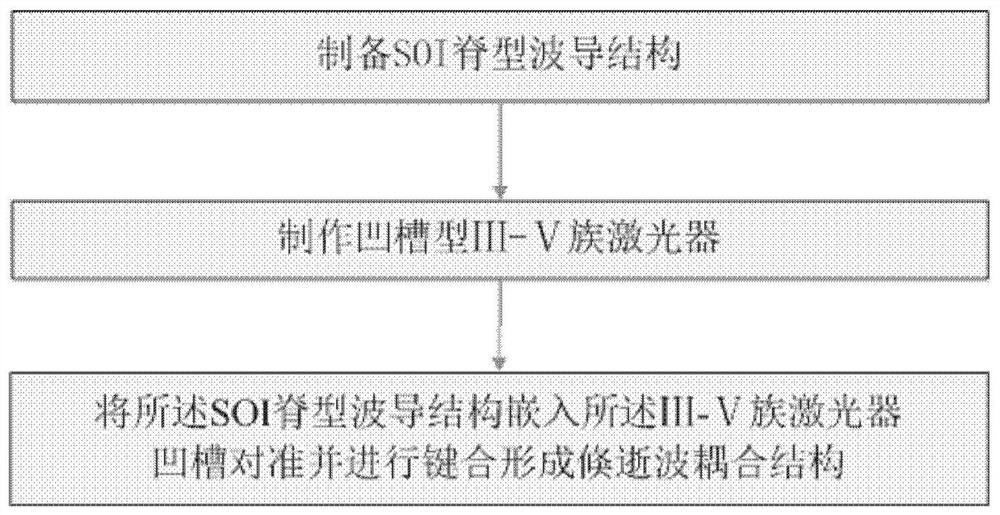

[0051] According to one embodiment of the present invention, there is provided a method for laser structure of III-V group / silicon material groove bonding, such as figure 1 Shown include:

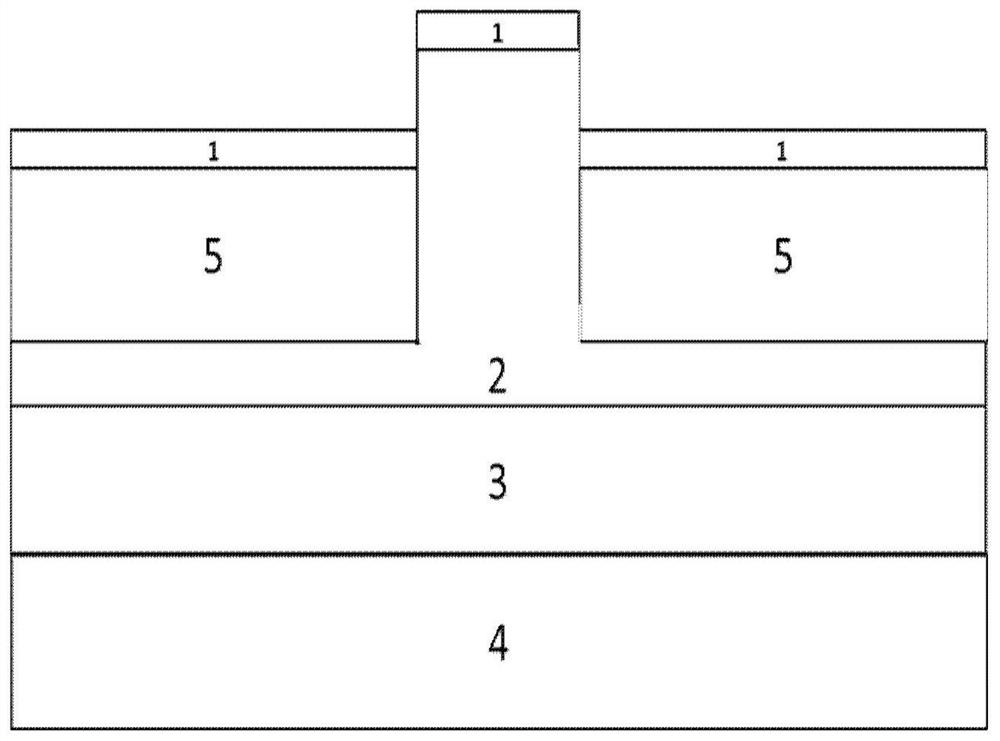

[0052] Step 1: preparing SOI ridge waveguide structure;

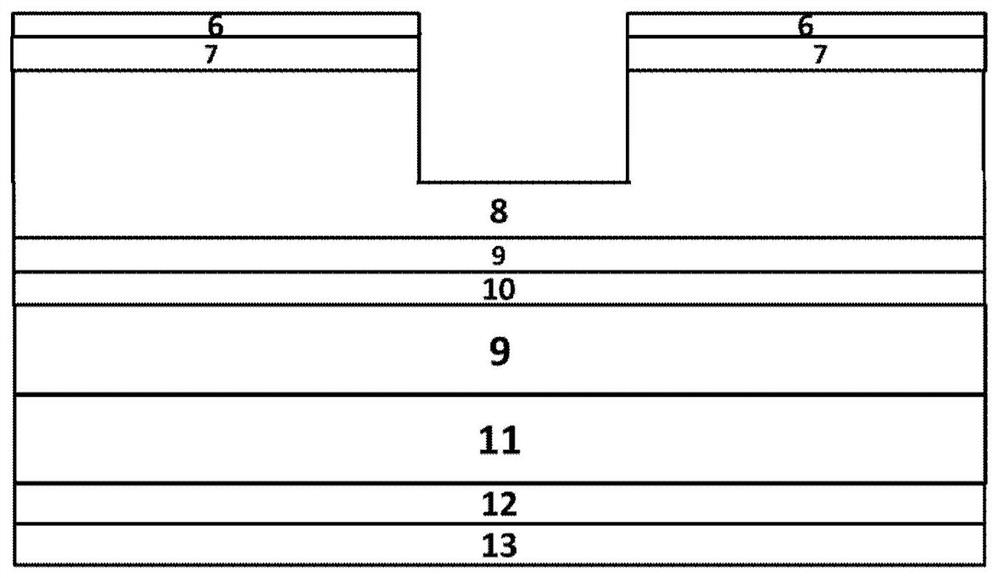

[0053] Step 2: Fabricate the groove type III-V group laser;

[0054] Step 3: Embedding the SOI ridge waveguide structure into the groove of the III-V laser for alignment and bonding. After bonding, an evanescent wave coupling structure is formed, and the laser light is coupled out from the SOI waveguide port.

[0055] Wherein, the order of step 1 and step 2 can be interchanged, that is, the order of preparing the ridge waveguide structure and manufacturing the III-V group lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com