Fuel cell metal bipolar plate

A metal bipolar plate and fuel cell technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of warping, reducing the flatness of bipolar plates, and easily breaking adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

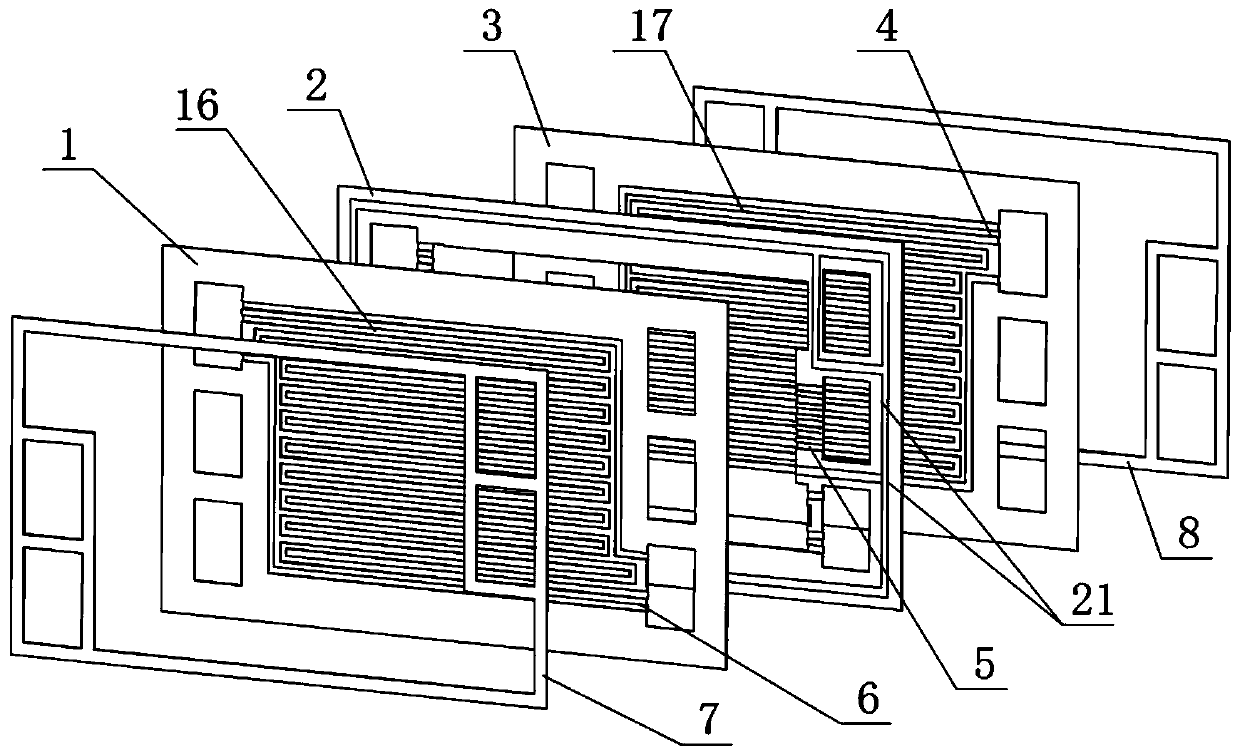

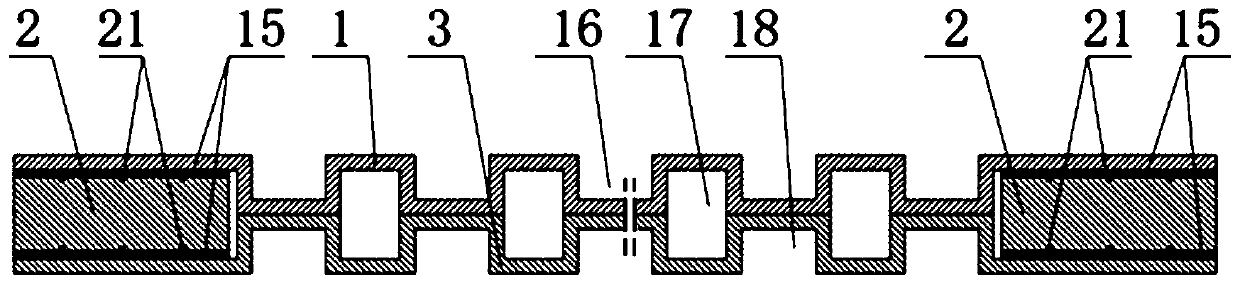

[0037] like figure 1 As shown, it is an exploded view of a metal bipolar plate, including a sealing gasket 7 , a cathode plate 1 , a gasket frame 2 , an anode plate 3 and a sealing gasket 8 arranged in sequence. The cathode plate 1 and the anode plate 3 are not provided with sealing grooves, and are sealed by the gasket 7 , the gasket 8 and the gasket frame 2 . The gasket a7 and the gasket b8 are in the shape of a square frame, and when the bipolar plate and the membrane electrode are assembled, they are sealed by the gasket.

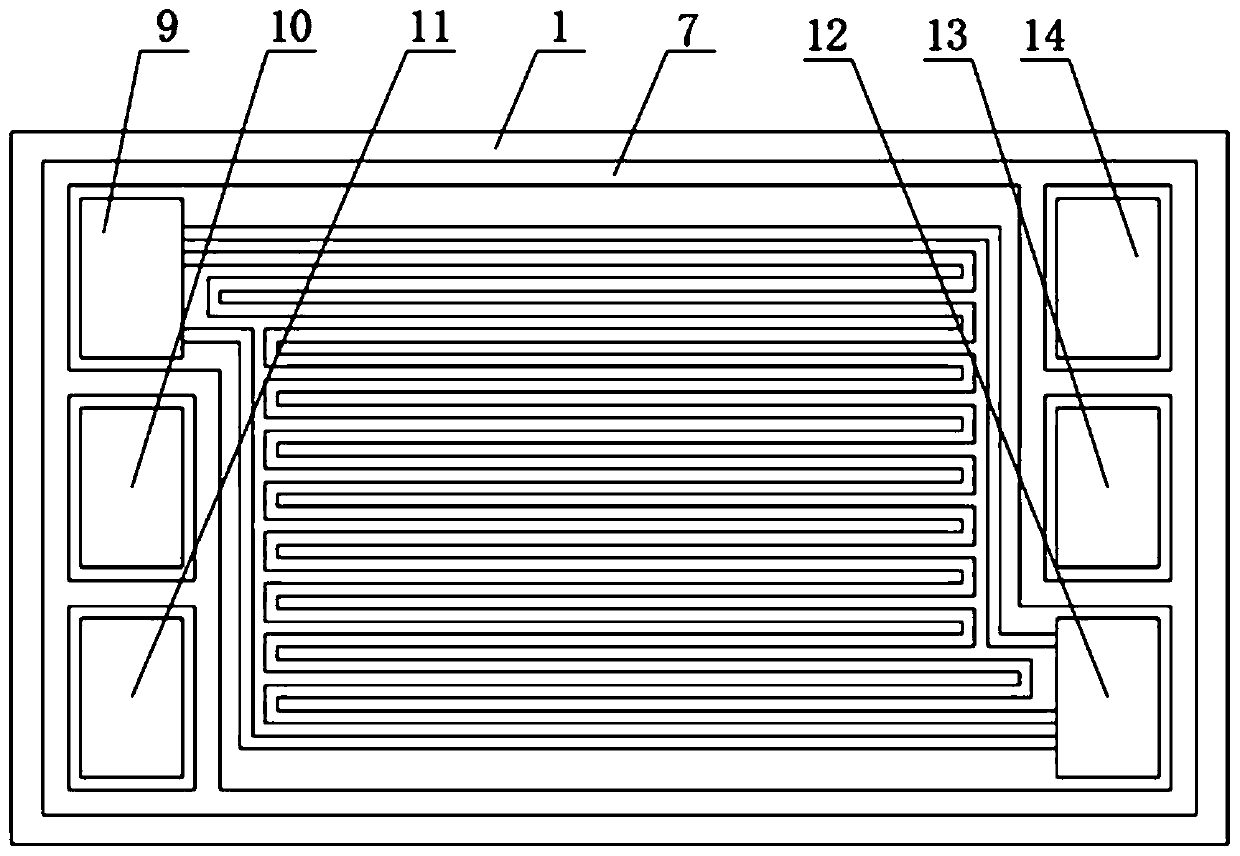

[0038] like figure 2 As mentioned above, it is a schematic diagram of the planar structure of the cathode plate. There are three inlets and three outlets on the board: oxidant inlet 9, oxidant drainage groove 6, oxidant outlet 12, fuel inlet 11, fuel drainage groove 4, fuel outlet 14, coolant inlet 10, Cooling liquid drainage groove 5, cooling liquid outlet 13, the positive side of the cathode plate 1 is provided with an oxidizing agent flow channel ...

Embodiment 2

[0044] like Figure 5 As shown, the coolant drainage groove 5 on the inside of the coolant inlet and outlet on the liner frame 2 selects a porous material 22 equivalent to the thickness of the liner frame, and the coolant enters from the coolant inlet 10 on the liner frame 2 through the porous material 22. The cooling liquid flow channel 17 enters the cooling liquid outlet 13 from the porous material on the other side and flows out.

[0045] The rest are the same as in Example 1.

Embodiment 3

[0047] like Image 6 As shown, the coolant drainage groove 5 on the inner side of the coolant inlet and outlet on the gasket frame 2 is made of a corrugated plate 23 with a thickness equivalent to the gasket frame, and the coolant passes through the corrugated plate 23 from the coolant inlet 10 on the gasket frame 2 into the cooling liquid flow channel 17, and then the porous material enters the cooling liquid outlet 13 and flows out from the other side. The front and back surfaces of the cathode plate and the anode plate have conductive anti-corrosion coatings, the coatings are sprayed after punching, and the coating materials are conductive anti-corrosion non-metallic materials.

[0048] The rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com