Novel 3D cake rapid molding machine

A molding machine and cake technology, applied in the direction of pre-baked dough processing, etc., can solve the problems of low precision, rigidity, and high cost of 3D printers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

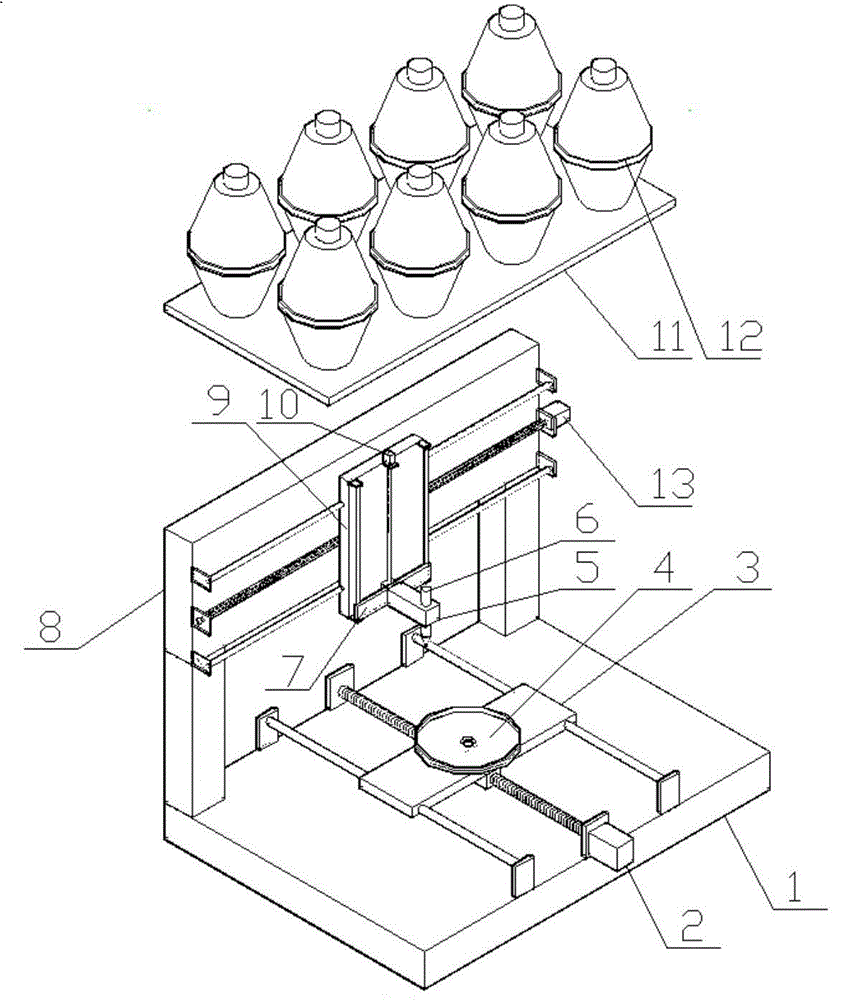

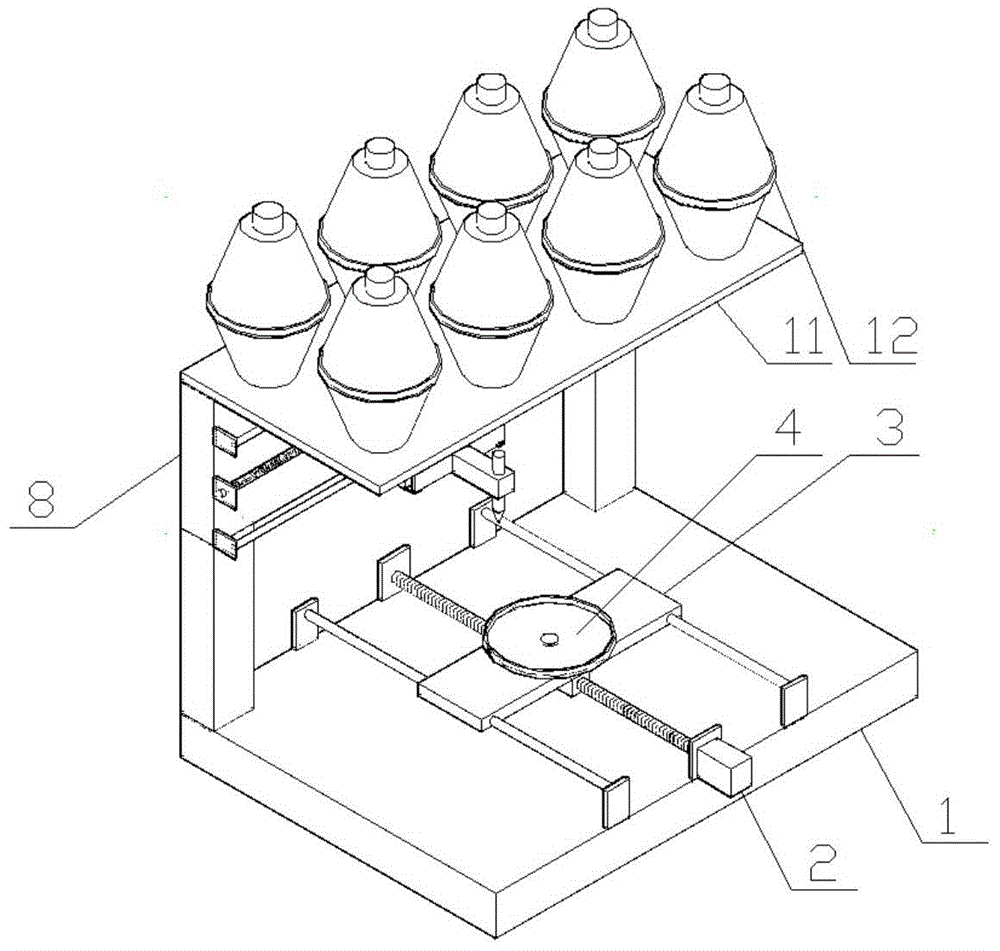

[0017] figure 1 with figure 2 Shown a specific embodiment of the present invention, a kind of novel 3D cake rapid forming machine of the present invention, comprises X moving plate 9, Y moving plate 3 and Z moving plate 7, and it passes X driving motor 13, Y driving motor 2 respectively Driven by Z drive motor 10;

[0018] The above-mentioned Y moving plate 3 is rotated and installed with a rotating base 4, and the above-mentioned Z moving plate 7 is arranged on the X moving plate 9;

[0019] A print head installation frame 5 is installed on the above-mentioned Z moving plate 7, and a print head 6 is vertically installed on the print head installation frame 5, and the top of the print head 6 is a feed port;

[0020] Also includes a base 1 and a support 8, the support 8 is arranged perpendicular to the base 1, the Y moving plate is arranged on the base 1, the X moving plate is arranged on the support 8, and a horizontal fixed plate 11 is installed on the top of the support 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com