Optimally elastic golf club head

a golf club head and elastic technology, applied in the field of optimal elastic golf club head, can solve the problems of poor performance, inability to exhibit the desired stiffness, and too stiff structure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

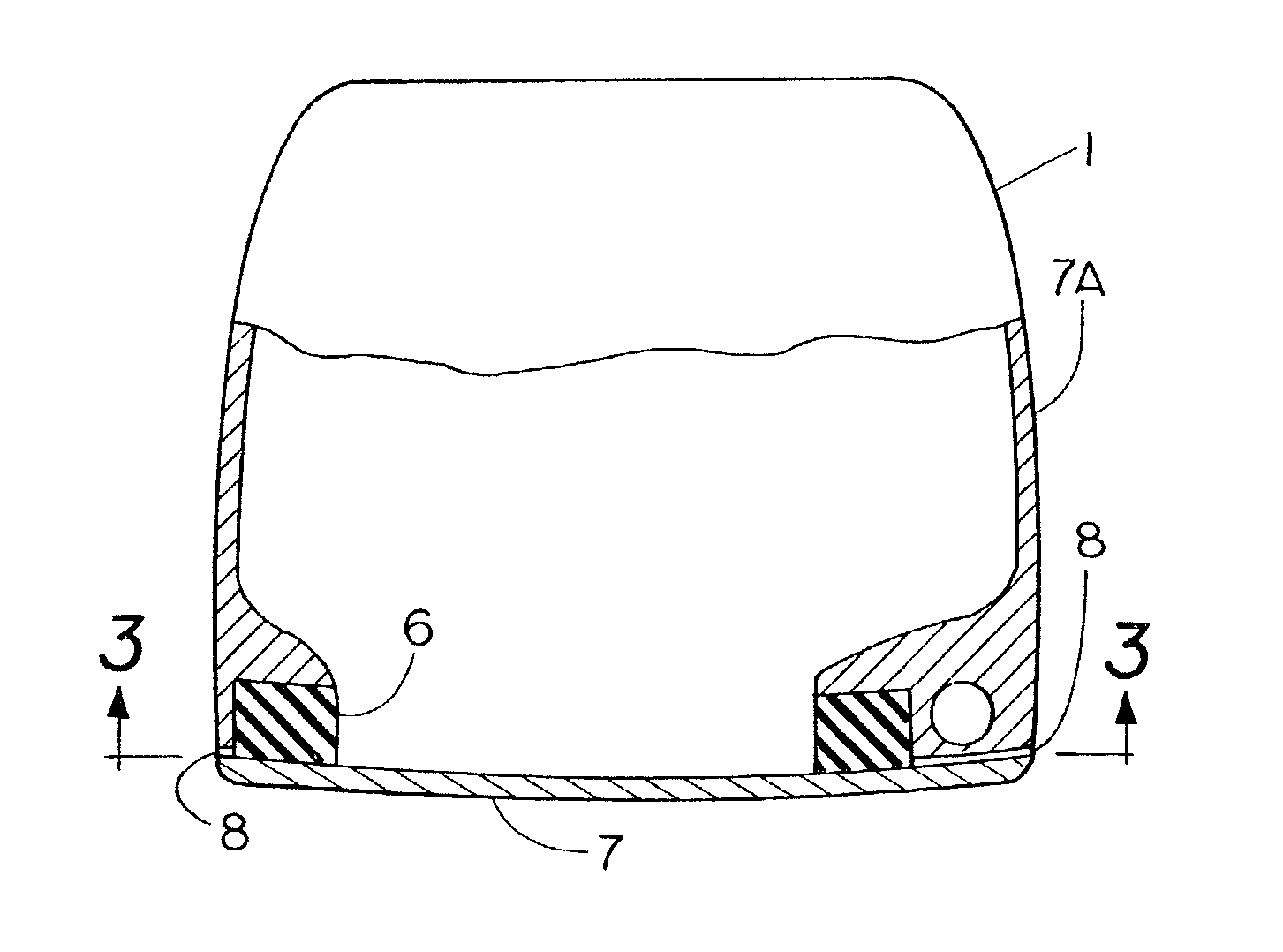

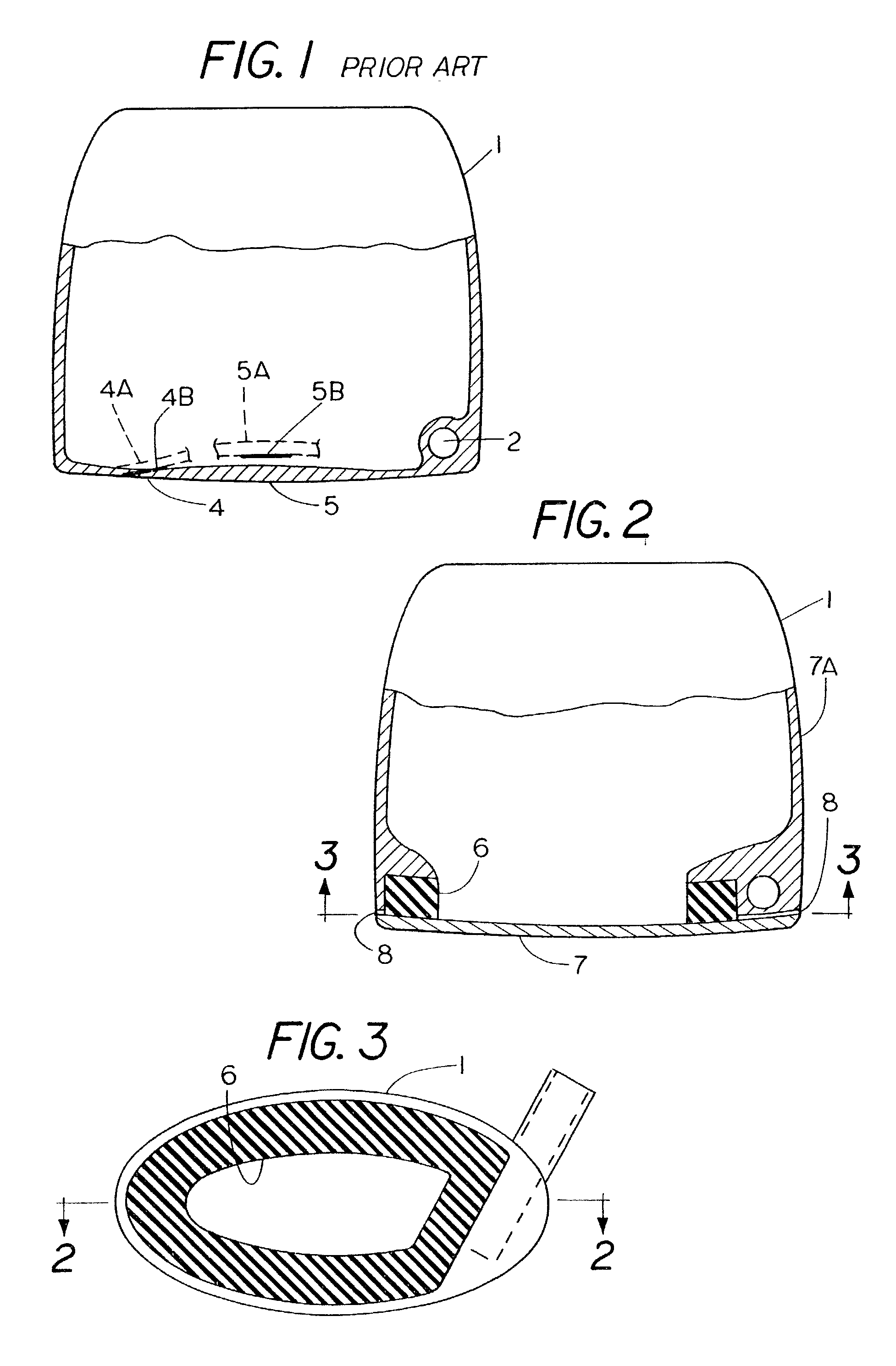

Embodiment Construction

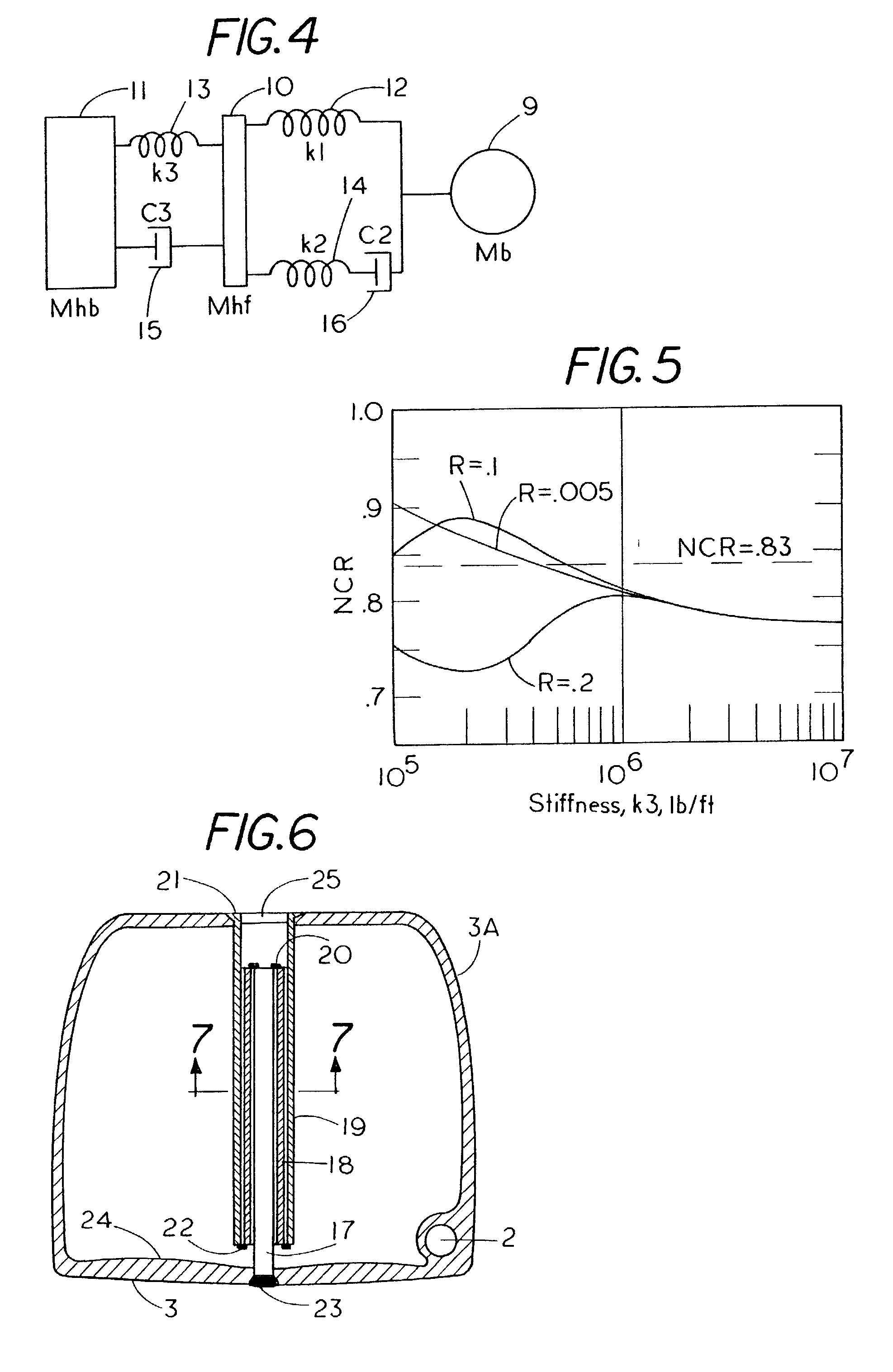

[0080] When stiffness, mass, and internal damping characteristics of the face have suitable values, the result is commonly called the "spring effect" or the "trampoline effect", and this can add 5 to 20 yards to a golfer's hit.

[0081] Off-center hits have basic differences from center hits. They must be studied by much more complicated analysis and / or evaluated experimentally. Off-center hits ordinarily give much less distance and altered launch direction of the ball for drives as compared to center hits. The design problem is generally to minimize this change of launch direction and this loss of distance. The stiffness, moment of inertia of the head, its face curvature, the amount of the off-center distance, the shear coefficient of restitution (or an equivalent), and other factors must be considered in addition to the concept of NCR.

[0082] The present inventors used computer-based analysis to study the face stiffness problem with a model of club head-ball impact which is illustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com