Production process for cover plate silicon-aluminum glass with capacitance touch function

A technology of silicon-alumina glass and touch function, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems affecting production efficiency and yield, difficult cutting, cracking, etc., to achieve finished products High efficiency, high cutting efficiency and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The production process of the cover silica-alumina glass with capacitive touch function is as follows:

[0024] (1) The silica-alumina glass is slit into the size of the base material and ground and chamfered; the silica-alumina glass substrate can be selected from Corning’s Gorilla, Asahi Glass’s DragonTrail and Schott’s Xensation. The thickness of the glass depends on the product requirements, and the general thickness is 0.4~ 3.0mm, preferably 300X400X1.1mm silica-alumina glass substrate;

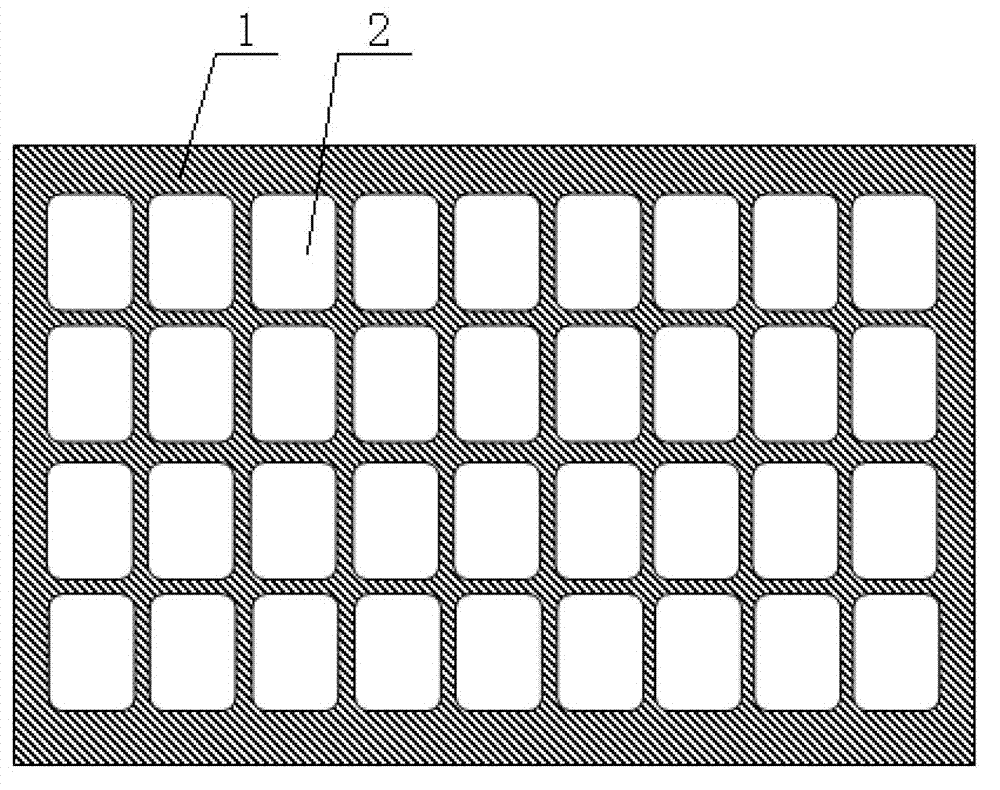

[0025] (2) Print a peelable protective film on both sides of the glass substrate by silk screen printing, see figure 1 It can be seen that the OGS product area 2 arranged in a grid shape divides the substrate into the coating area 1 and the OGS product area 2, and the protective film covers the upper and lower surfaces of the OGS product area 2. The protective film is a single-component thermosetting adhesive for screen printing. As a protective coating, it has the function of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com