Segmented silicon carbide liner

A silicon carbide, segment technology, applied in the design of bonding materials and joints, in the field of silicon carbide materials, can solve problems such as material contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

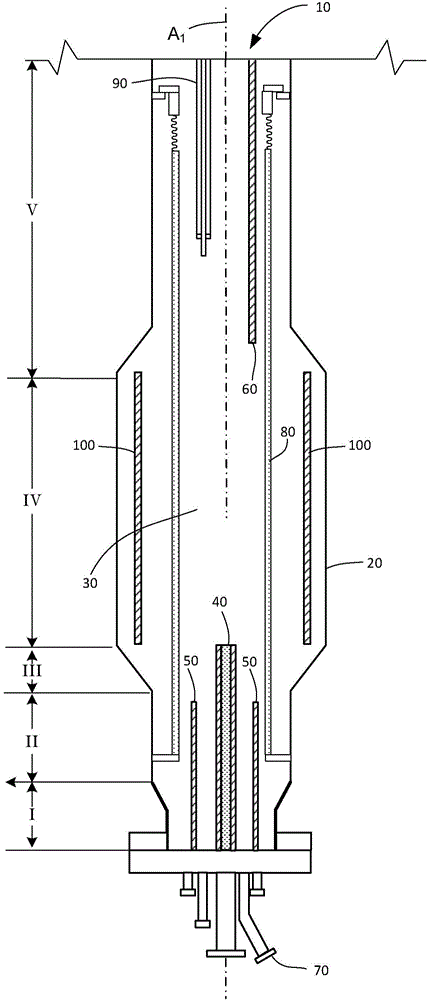

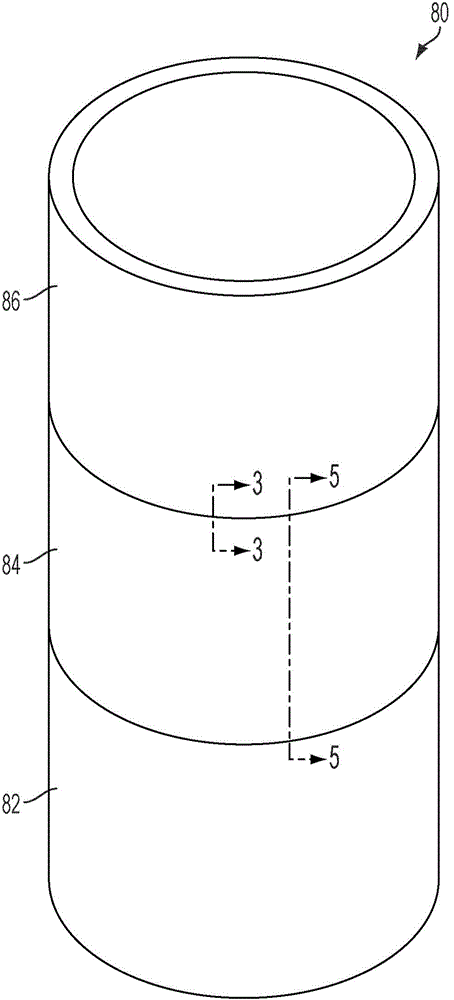

Method used

Image

Examples

Embodiment 1

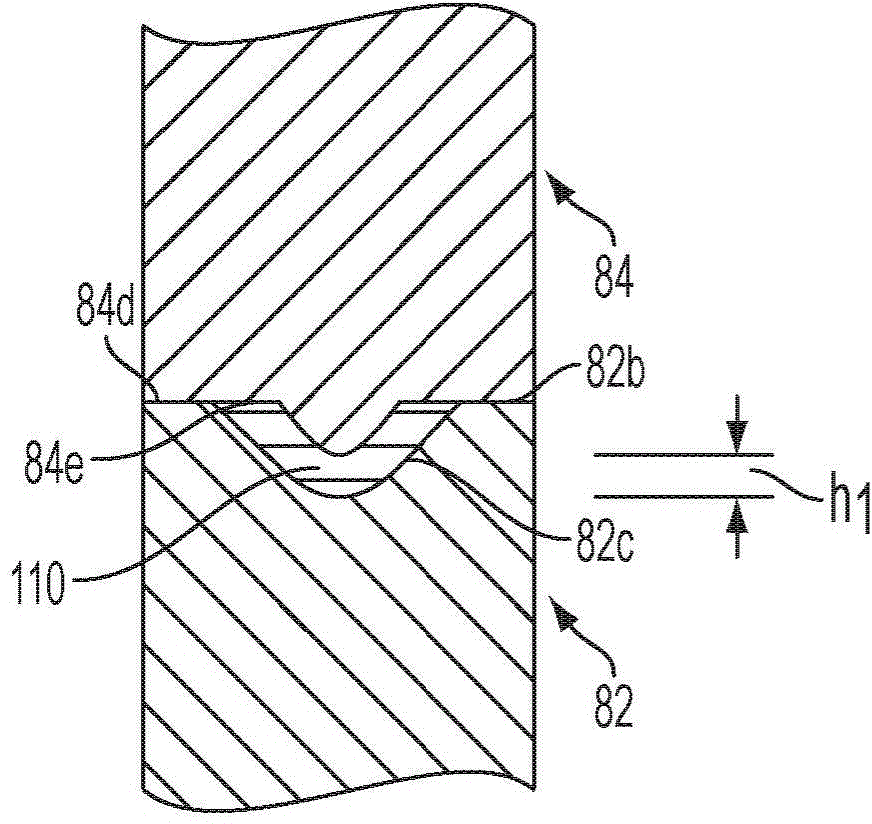

[0122] Evaluation of Adhesive Materials

[0123] Bonding materials based on potassium and lithium silicates are commercially available, such as Ceramabond 890-K and 890-L, where K and L refer to potassium and lithium, respectively (Aremco Products, Inc., Valley Cottage, NY). Both bonding materials include fine silicon carbide particles as filler and aluminosilicate as thickener. Adhesive materials are available as pre-mixed slurries.

[0124] Mix each bonding material well before use by shaking for 5 minutes or stirring with a mechanical stirrer. Clean the surface of the silicon carbide joint with a metal brush and wipe it with a clean cloth. Use a spatula to apply the bonding material to the mating pin and box (ie tongue and groove joint). Wipe off excess adhesive material. Typically, 3 pairs of silicon carbide segments (5-8 cm long) were tested per set of conditions to ensure repeatability. Press and clamp the male and female fittings together. The clamped joints were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com