Polishing pad and multi-layer polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

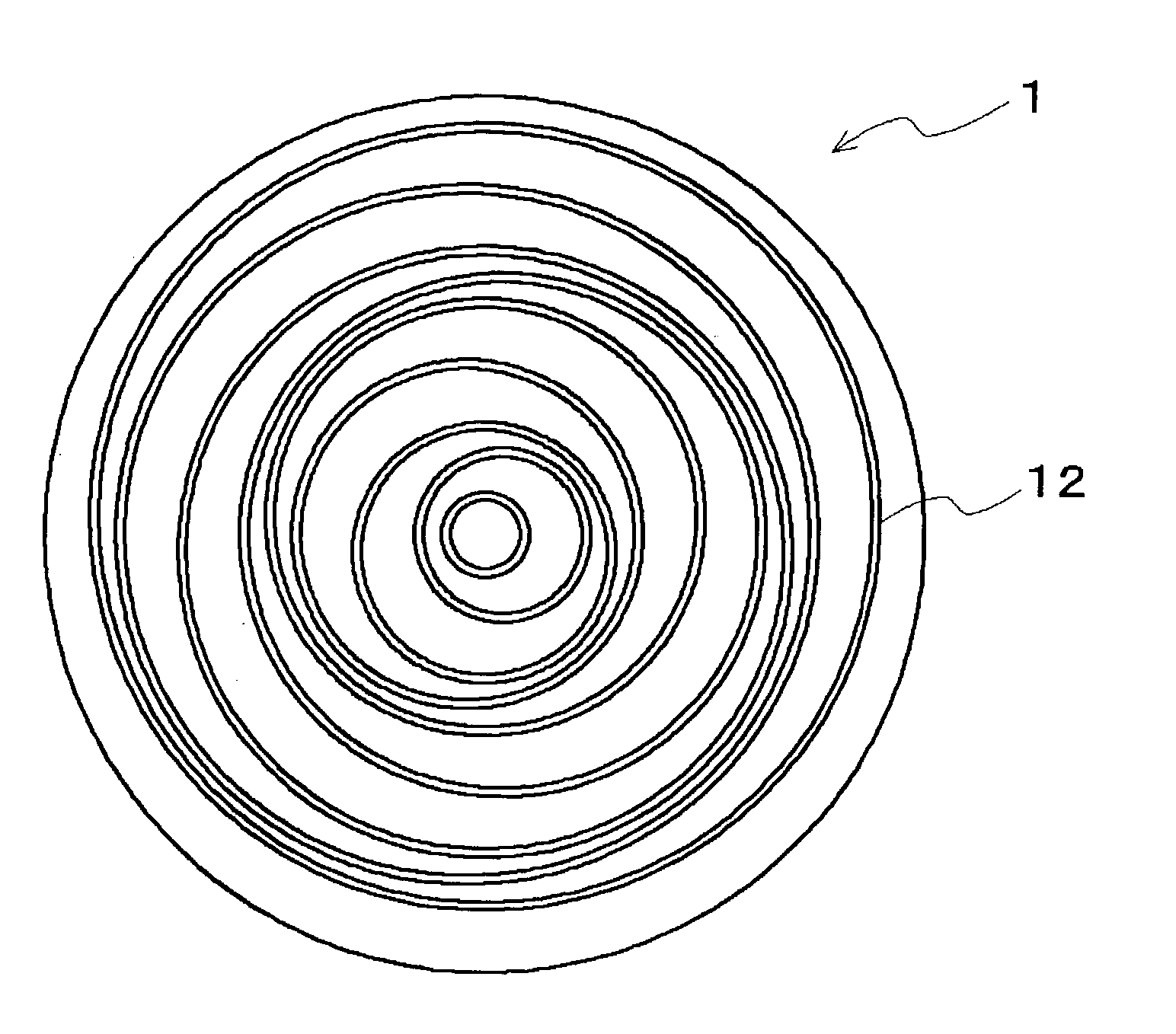

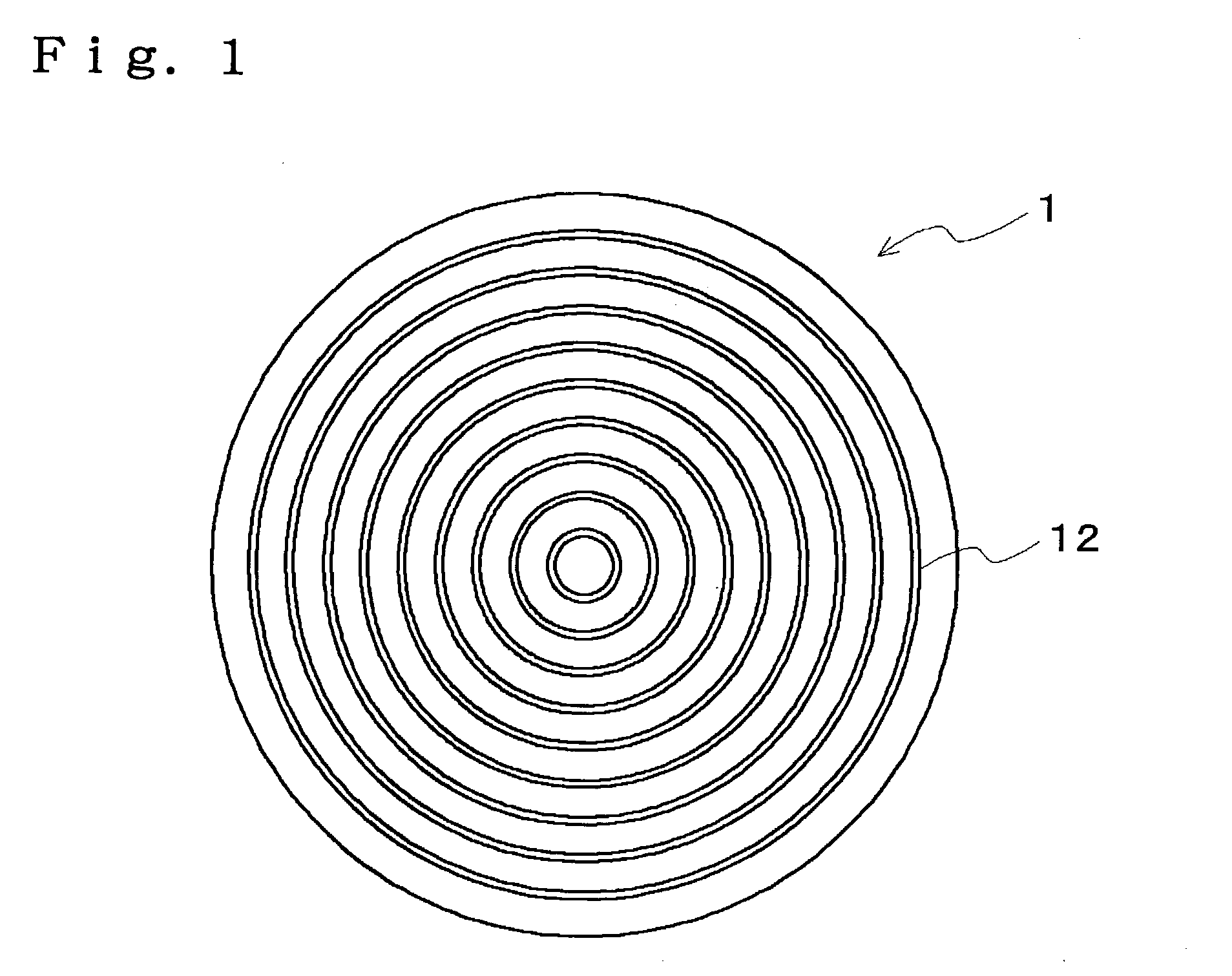

example 1-1

[0133] 80 parts by volume of 1,2-polybutadiene (Trade name "JSR RB830" manufactured by JSR Corp.) that becomes a water-insoluble matrix by crosslinking and 20 parts by volume of .beta.-cyclodextrin (Trade name "Dexipearl .beta.-100" manufactured by Bio Research Corporation of Yokohama, average particle diameter; 20 .mu.m) that as a water-soluble particle were kneaded with a screw extruder that is temperature-controlled at 160.degree. C., and thereby white pellet was obtained. Thereafter, 0.3 parts by volume of organic peroxide (Trade name "Percumyl D-40" manufactured by NOF Corp.) were compounded and further kneaded at 120.degree. C.; the kneaded material was extruded into a die and heated at 170.degree. C. for 18 minutes to crosslink; and thereby a disc-like molded body having a diameter of 60 cm and a thickness of 2.5 mm was obtained. Thereafter, concentric circle-like grooves in which a width is 0.5 mm, a depth is 1 mm, a pitch is 1.5 mm and a length between adjacent grooves is 1...

example 1-2

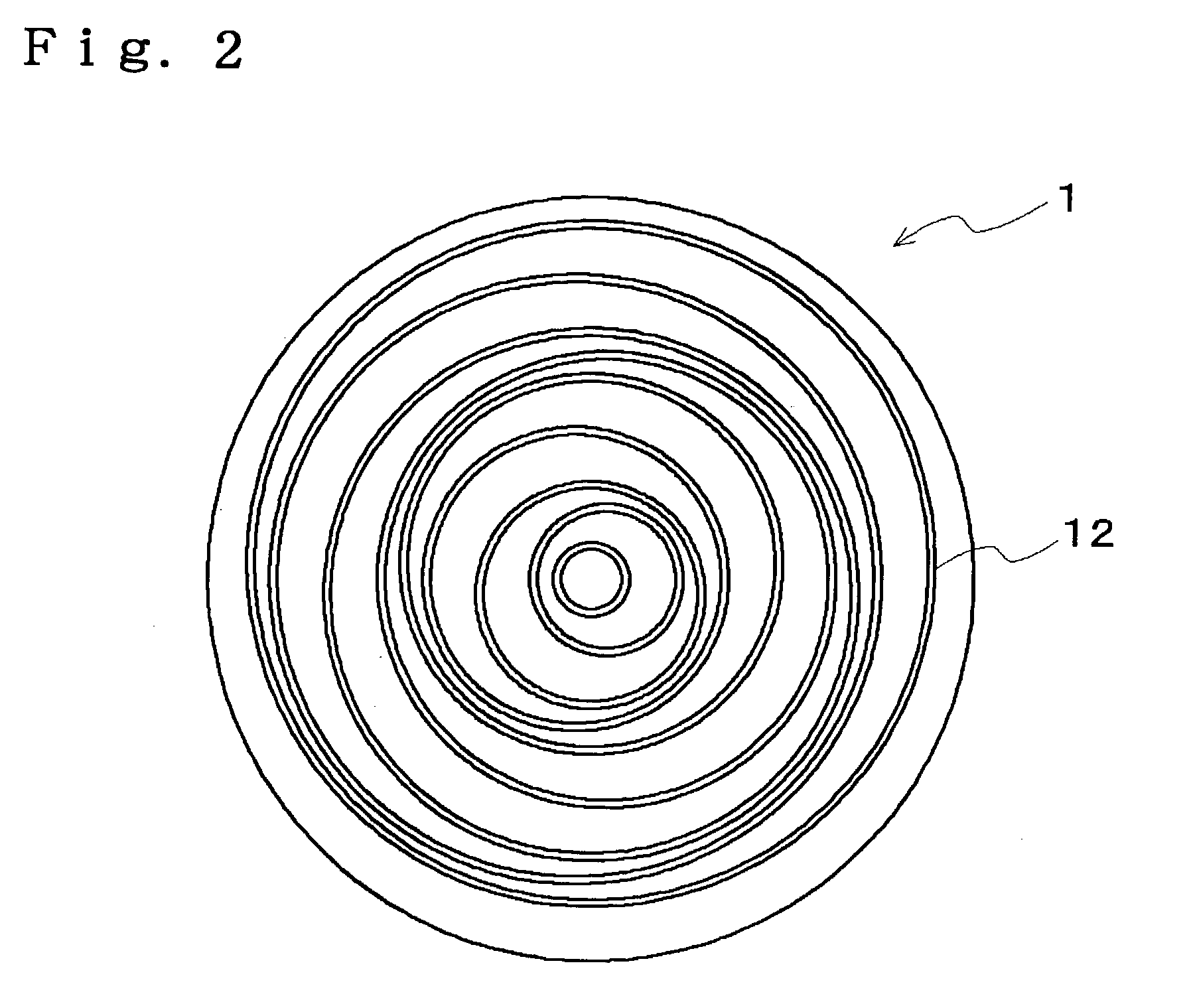

[0136] 100 parts by volume of 1,2-polybutadiene (Trade name "JSR RB840" manufactured by JSR Corp.) that becomes a water-insoluble matrix by crosslinking and 100 parts by volume of a water-soluble particle (average particle diameter: 20 .mu.m) obtained by coating polypeptide on .beta.-cyclodextrin (Trade name "Dexipearl .beta.-100" manufactured by Bio Research Corporation of Yokohama) were kneaded with a screw extruder that is temperature-controlled at 160.degree. C., and thereby white pellet was obtained. Thereafter, 0.3 parts by volume of organic peroxide (Trade name "Perhexine 25B" manufactured by NOF Corp.) were compounded with the white pellet and further kneaded at 120.degree. C., and thereby white pellet was obtained. In the next place, the organic peroxide-added white pellet was introduced into a die and heated at 190.degree. C. for 10 minutes to crosslink; and thereby a disc-like molded body having a diameter of 60 cm and a thickness of 2.5 mm was obtained. Thereafter, on on...

example 2-1

[0153] On one surface side of the disc-like molded body that was obtained in Example 1-1 and had a diameter of 60 cm and a thickness of 2.5 mm, lattice-like grooves in which a width is 0.5 mm, a depth is 1 mm, a longitudinal pitch is 5 mm and a transverse pitch is 5 mm, and a planar shape of one pattern that forms a lattice is a square shown in FIG. 4 were formed with a cutting machine manufactured by Kato Kikai Co., Ltd.

[0154] In the next place, from the obtained polishing pad, a slice for use in surface roughness measurement was cut so that a groove might be included in a width direction. Thereafter, the surface roughness Ra of an inner surface of the groove was measured in three different view fields of the slice with the above-mentioned three-dimensional surface structure analytic microscope. As a result, the surface roughness Ra was 2.5 .mu.m.

[0155] A section of a part of the groove for the polishing pad was enlarged and observed with an optical microscope. The obtained microgr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com