Dust reduction type steel plate double-face efficient polishing device

A steel plate and double-sided technology, which is applied in the field of high-efficiency double-sided grinding of dust-reducing steel plates, can solve the problems of inconvenient steel plate double-sided grinding operation, poor steel plate grinding effect, poor steel plate turning effect, etc., and achieve good dust removal and dust reduction effects, grinding Wide-ranging, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

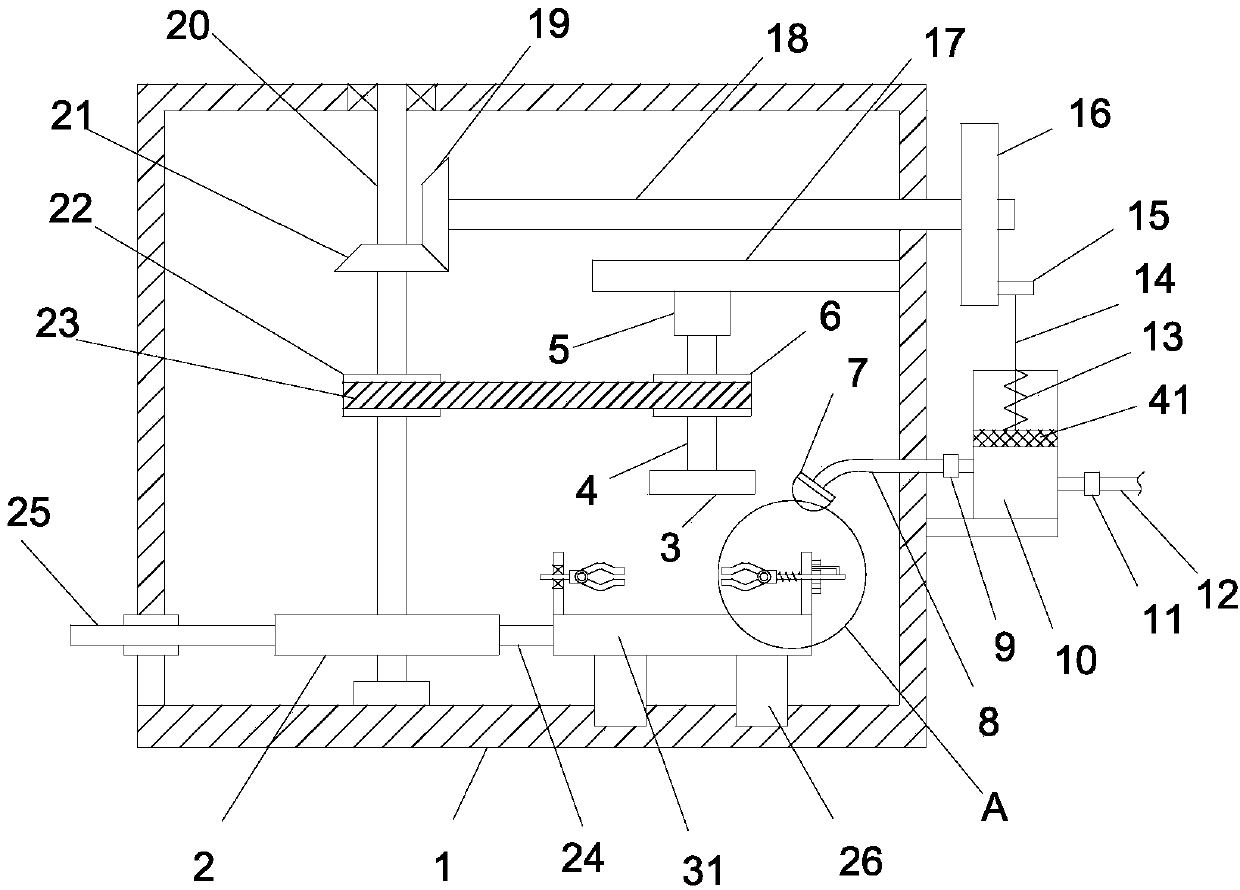

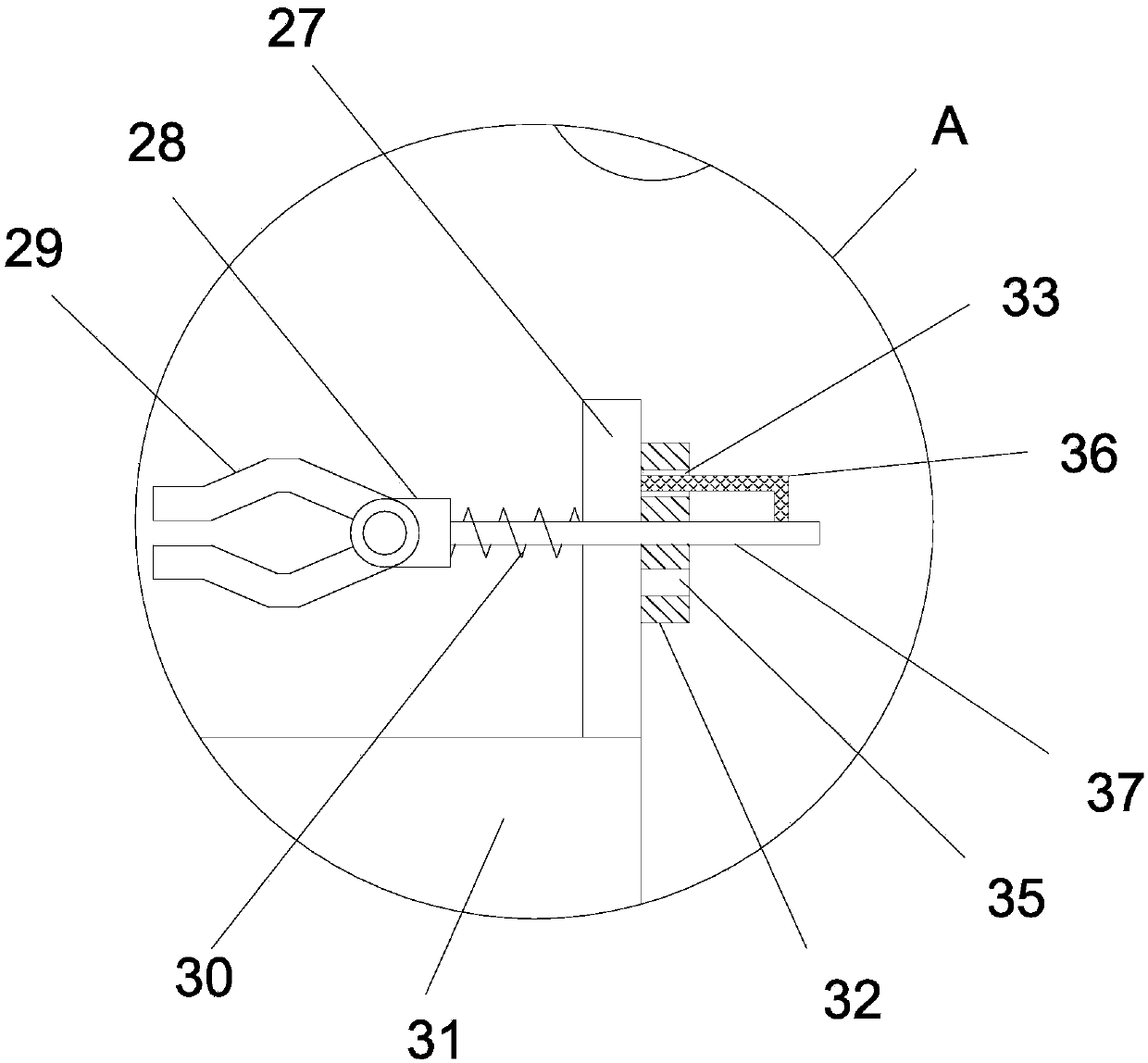

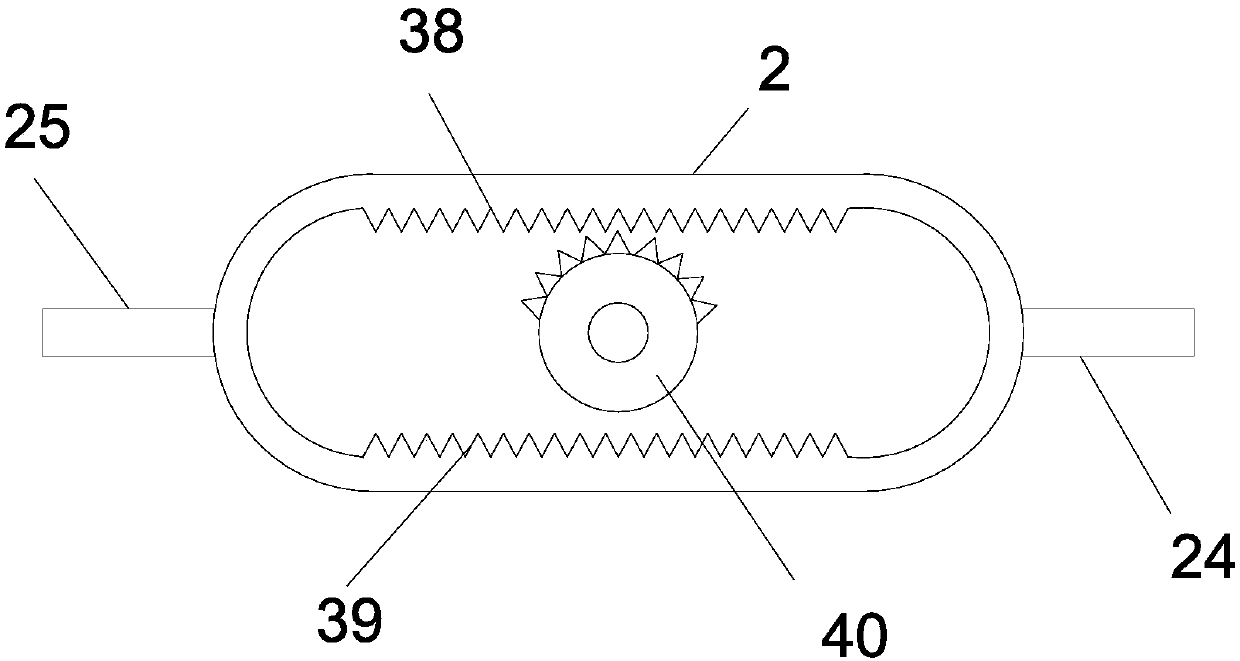

[0020] see Figure 1-4 , a double-sided high-efficiency grinding device for dust-reducing steel plates, including an operating room 1, wherein a driven shaft 20 is vertically rotated in the operating room 1, and a driven pulley 22 and a driving bevel gear are arranged on the driven shaft 20 21. In the operating room 1, there is a horizontal rotation shaft 18, and the left end of the rotating shaft 18 is coaxially fixed with a driven bevel gear 19 meshed with the driving bevel gear 21; There is an extension plate 17 extending to the left, and the bottom surface of the extension plate 17 is fixed with a driving motor 5 upside down. A drive belt 23 is wound around the driven pulley 22; a grinding plate 3 is fixedly mounted on the bottom end of the drive shaft 4; The first spur rack 38 and the second spur rack 39 are parallel to each other, and the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com